Copper Mesh Production Ramps Up in China to Meet Growing Demand

By:Admin

{Brand Name Removed} has established an enviable reputation for itself in the manufacturing and production of copper mesh. The company combines innovation, quality control, and customer satisfaction to produce an exceptional product that meets the needs of its clients.

The use of copper mesh finds relevance in several industries, ranging from electronics to medical equipment and filtration systems. It is a highly versatile material that is prized for its anti-corrosion properties and high thermal conductivity. Copper mesh is used in electroplating, cathodic protection, radio frequency shielding, and many other applications that require a high level of electrical conductivity.

{Brand Name Removed} recognized the importance of copper mesh and has over the years invested in technology and innovation to produce high-quality copper mesh products. The company's copper mesh is produced using the latest manufacturing techniques and equipment that ensures that the final product meets the highest industry standards.

One of the key advantages of using {Brand Name Removed} copper mesh is its durability. The company's copper mesh is resistant to corrosion, making it the ideal material for use in harsh environments. It is also easy to cut and shape, making it suitable for use in intricate designs.

Another feature that makes {Brand Name Removed} copper mesh stand out is its efficiency in current conduction. The mesh is highly conductive, making it ideal for use in systems that require high current flow rates. The high conductivity of the mesh ensures that current flows smoothly through the system, reducing the risk of damage due to overheating.

The company's commitment to quality also means that it conducts rigorous quality control checks to ensure that each batch of copper mesh produced meets the highest standards. Each batch is checked for consistency in thickness, conductivity, and other mechanical properties.

{Brand Name Removed} copper mesh is available in a wide range of sizes, making it easy for clients to find the perfect copper mesh for their specific needs. The company also provides customized solutions to clients who require copper mesh products that are tailored to their unique specifications.

One noteworthy application of {Brand Name Removed} copper mesh is in the medical industry. The mesh is used in wound healing and tissue engineering applications, thanks to its biocompatibility and flexibility. The copper mesh can be molded into complex shapes, making it ideal for use in reconstructive surgeries.

In conclusion, {Brand Name Removed} has set the standard for high-quality copper mesh production in China and beyond. The company's commitment to innovation, quality control, and customer satisfaction have earned it a reputation as a trusted partner in the manufacturing industry. With its wide range of sizes and customized solutions, {Brand Name Removed} copper mesh is the go-to material for clients looking for high quality, dependable copper mesh products.

Company News & Blog

Top-quality Square Mesh: Unleashing the Potential of Stainless Steel

Stainless Steel Square Mesh Revolutionizes Industrial ApplicationsInnovation has always been at the forefront of industrial progress, and one company is at the helm of introducing a ground-breaking solution that is set to revolutionize industrial applications. In this era of technological advancements, Stainless Steel Square Mesh (name removed for confidentiality) has emerged as a leading provider of high-quality stainless steel mesh products, catering to various industries worldwide.With over a decade of experience, Stainless Steel Square Mesh prides itself on its commitment to excellence and customer satisfaction. Renowned for its ability to deliver customized solutions, the company has successfully established itself as a trusted partner for businesses seeking durable and reliable stainless steel mesh products.The stainless steel square mesh offered by the company is a true game-changer, offering a multitude of applications across industries such as construction, filtration, agriculture, and mining. The unique fabrication process ensures that each mesh is of premium quality, exhibiting exceptional strength, durability, and resistance to corrosion - making it a reliable choice for even the most demanding environments.One of the key advantages of Stainless Steel Square Mesh is its versatility. The product can be tailored to meet specific requirements, offering various mesh sizes, wire thicknesses, and dimensions to suit diverse applications. This flexibility allows businesses to optimize their operations while minimizing costs and maximizing efficiency.In the construction industry, Stainless Steel Square Mesh finds numerous applications. From reinforcing concrete structures to providing support for tiles and flooring, the mesh excels at improving the strength and stability of various construction projects. With its anti-rust properties, it ensures that these structures stand the test of time, even in challenging environments.Furthermore, the filtration industry can greatly benefit from the stainless steel square mesh. By providing an excellent medium for sieving and filtering processes, it allows for efficient separation of particles, ensuring the purity and quality of end products. Whether it is water treatment, oil filtration, or food processing, the mesh guarantees optimal performance and longevity, reducing maintenance and replacement costs.In the agricultural sector, Stainless Steel Square Mesh has proven to be an indispensable tool. It serves as an effective barrier against pests, allowing ventilation and sunlight to reach crops while preventing unwanted intrusions. The durability of the mesh ensures that it remains intact amidst harsh weather conditions, protecting crops and maximizing yields.The mining industry also stands to benefit from the superior characteristics of Stainless Steel Square Mesh. Used as screens for mineral separation, the mesh ensures precise and efficient sorting, leading to increased productivity and profitability. Its durability and resistance to corrosion make it an ideal choice in this demanding and abrasive environment.Stainless Steel Square Mesh's commitment to delivering quality products extends beyond the manufacturing process. The company's customer service is recognized for its professionalism and efficiency. With a dedicated team of experts, they provide technical support and guidance, ensuring that clients receive tailored solutions that meet their specific needs.The industry is taking notice of Stainless Steel Square Mesh's contributions and advancements. Its products have achieved significant recognition, garnering prestigious awards for their quality, innovation, and environmental sustainability.As industries continue to evolve, Stainless Steel Square Mesh remains dedicated to pushing boundaries and setting new standards. With a steadfast commitment to excellence, the company stands as a catalyst for progress, enabling businesses to thrive and achieve new levels of success in their respective industries.In conclusion, Stainless Steel Square Mesh (name removed for confidentiality) has emerged as a leading provider of stainless steel mesh products that are transforming industrial applications. Through its commitment to quality, customization, and innovation, the company has established itself as a trusted partner for businesses worldwide. With its versatile applications and exceptional durability, Stainless Steel Square Mesh is poised to redefine standards, shape industries, and drive global progress.

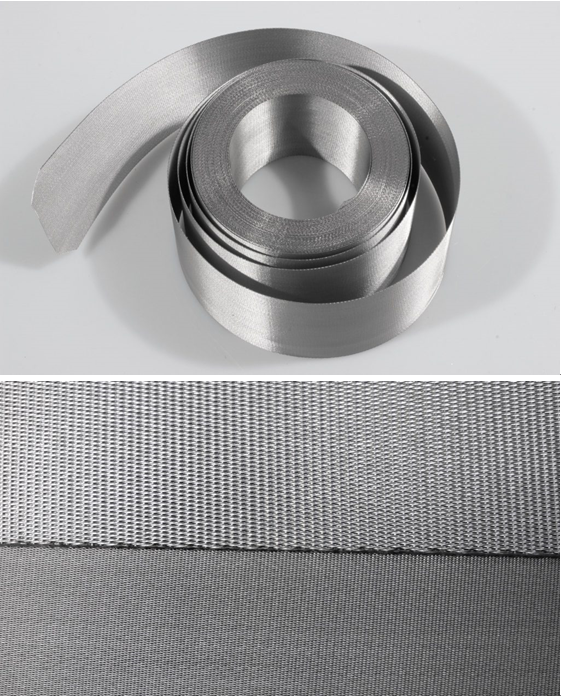

Introduction to Plain Weave: A Versatile and Widely Used Wire Mesh

Plain weave wire mesh is a versatile and widely used material in a variety of industries. Its unique construction and properties make it an ideal option for a range of applications, making it a popular and reliable choice for many different purposes. Whether you are looking for a material that is durable, flexible, or easy to work with, plain weave wire mesh is a great option to consider.One of the main benefits of plain weave wire mesh is its simplicity. The weave is made by running wires parallel to each other in one direction, and then weaving other wires perpendicular to them. This creates a mesh pattern that is uniform and consistent, with each wire evenly distributed throughout the fabric. This simple construction makes the material easy to work with, and allows it to be used in a variety of different ways.One of the most common uses for plain weave wire mesh is in the construction of screens and filters. Its fine mesh pattern allows air and liquid to pass through, while keeping out larger particles and debris. This makes it a popular choice for applications such as window screens, dust covers, and HVAC systems.In addition to its use as a filter or screen, plain weave wire mesh is also frequently used for reinforcement and support. Its strong construction makes it ideal for use in industrial settings, where it can help to add strength and stability to machinery and other equipment. It is also commonly used in construction, where it can serve as a reinforcing material for building materials such as concrete and plaster.Plain weave wire mesh is also a popular option for decorative purposes. Its uniform, grid-like pattern can be visually appealing, and it is often used for decorative accents or to add texture to surfaces such as walls and ceilings. It can also be used in art and design, where its unique properties can be used to create interesting and dynamic pieces.Overall, plain weave wire mesh is a highly versatile and useful material that can be used in a variety of different applications. Whether you are looking for a material that is strong, flexible, or visually appealing, plain weave wire mesh is a great option to consider. So if you are in need of a reliable and high-quality material for your next project, be sure to check out plain weave wire mesh and see how it can work for you.

Stylish Copper Kitchen Cabinet Hardware Pulls with Hammered Texture

Hammered Kitchen Pulls, Copper Hardware Cloth, Satin Copper Kitchen Hardware Pulls, Copper Kitchen Cabinet Hardware PullsWhen it comes to designing and upgrading your kitchen, the smallest details can often make the biggest impact. One such detail that can instantly elevate the aesthetic of your kitchen is the choice of hardware pulls. And if you're looking for something unique and stylish, copper hardware pulls might just be the perfect option for you.Copper hardware pulls have been gaining popularity in recent years, and it's easy to see why. With their warm and rich color, they add a touch of elegance and sophistication to any kitchen. Whether you have a traditional or modern kitchen, copper pulls can seamlessly blend in and complement your existing decor.One type of copper hardware pull that stands out is the hammered kitchen pull. With its textured surface, it adds a rustic and handcrafted feel to your cabinets or drawers. The hammered finish gives it a unique and one-of-a-kind look that can't be replicated with other materials. If you're aiming for a farmhouse or industrial style kitchen, hammered copper pulls are the perfect choice.Besides the aesthetic appeal, copper hardware pulls also offer practical benefits. Copper is known for its antimicrobial properties, which means it naturally inhibits the growth of bacteria and other harmful microorganisms. In a kitchen where hygiene is crucial, copper pulls can help keep your space clean and safe.When choosing copper hardware pulls for your kitchen, there are different finishes to consider. Satin copper pulls have a smooth and brushed appearance, offering a more contemporary and refined look. They work well in modern kitchens and can add a touch of luxury to your space. On the other hand, if you prefer a more vintage or antique feel, you can opt for polished copper pulls. The shiny and reflective surface adds a nostalgic charm to your cabinets and drawers.Copper hardware pulls are versatile and can be paired with various cabinet and drawer styles. They can effortlessly complement white cabinets, creating a stunning contrast and adding warmth to the overall design. Whether you have a sleek and minimalist kitchen or a traditional and cozy one, copper pulls can enhance the overall aesthetic and tie the whole look together.If you're concerned about the durability of copper pulls, rest assured that they are built to last. Copper is a sturdy and resilient material that can withstand everyday wear and tear. Over time, it develops a beautiful patina that only adds to its charm and character. However, if you prefer to maintain the shiny appearance, regular polishing can easily restore its original luster.In conclusion, copper hardware pulls, particularly hammered kitchen pulls, are an excellent choice for adding style and elegance to your kitchen. The unique texture and warm color of copper can instantly enhance the aesthetic of your cabinets and drawers. Whether you prefer a contemporary or vintage look, copper pulls come in different finishes to suit your personal style. Not only are they visually appealing, but copper pulls also offer practical benefits with their antimicrobial properties. So, if you're looking to make a statement in your kitchen, consider investing in copper hardware pulls for a touch of timeless beauty.

High-Pressure Filter Elements: Enhancing Filtering Efficiency

Title: Cutting-Edge High Pressure Filter Element Revolutionizes Filtration TechnologyIntroduction:In today's rapidly advancing industrial sector, businesses are constantly searching for innovative solutions to enhance operational efficiency, productivity, and environmental sustainability. Strengthening this quest further, an industry-leading company has recently unveiled its groundbreaking High Pressure Filter Element, poised to revolutionize the filtration technology landscape. By effectively removing contaminants from fluids under high-pressure circumstances, this cutting-edge filter element promises to deliver superior performance, exceptional quality, and unparalleled reliability across a wide range of industries.Main Body:1. The Need for Advanced Filtration Technology (100 words)In industries dealing with high-pressure fluid systems, such as oil and gas, automotive, manufacturing, and aerospace, the demand for robust and efficient filtration technology is paramount. Contaminants, such as particles, oil varnish, water, and other impurities, can greatly impact the performance and longevity of critical components. Hence, the introduction of the High Pressure Filter Element is a significant development, as it addresses these challenges with its advanced filtration capabilities.2. Unveiling the High Pressure Filter Element (150 words)Manufactured by a globally recognized company committed to technological advancements and customer satisfaction, the High Pressure Filter Element incorporates state-of-the-art design principles and cutting-edge materials. Its unique construction ensures exceptional strength, longevity, and unrivaled filtering performance, making it the ideal choice for high-pressure filtration applications. The innovative design consists of multiple layers of advanced filtration media that allow for efficient removal of contaminants without compromising fluid flow rates.3. Superior Performance and Efficiency (150 words)The High Pressure Filter Element has been extensively tested and validated to provide remarkable filtration efficiency, capable of removing particles as small as a few microns. This ensures that the filtered fluid meets or exceeds industry cleanliness specifications, safeguarding the integrity of vital equipment and reducing maintenance costs. The filter element's high dirt-holding capacity prolongs service intervals, resulting in improved operational uptime and reduced downtime. Moreover, its robust construction enables reliable operation even under extreme pressures and fluctuating conditions, ensuring consistent and high-quality filtration performance.4. Versatility and Customization Options (150 words)Recognizing the diverse needs of various industries, the High Pressure Filter Element offers a wide array of options and customization possibilities. Clients can choose from a range of filtration ratings, sizes, and configurations to match their specific requirements. With compatibility across multiple fluids, including hydraulic oils, lubricants, coolants, and process fluids, this versatile filter element caters to a broad range of applications. Additionally, advanced monitoring features such as pressure differential indicators and bypass valves can be incorporated to enhance the system's functionality and provide improved filter element change-out timelines.5. Environmental Sustainability and Cost Savings (150 words)Apart from its exceptional performance and versatility, the High Pressure Filter Element contributes significantly to environmental sustainability efforts. By effectively removing contaminants, it helps extend the service life of equipment, reducing the need for frequent component replacements, and minimizing waste generated from maintenance activities. As a result, businesses can experience substantial cost savings in terms of replacement parts, downtime, and disposal. Furthermore, the filter element's optimized design and advanced materials promote energy efficiency, ensuring that the filtration process consumes minimal power, which aligns with the company's commitment to reducing carbon footprints.Conclusion:The introduction of the High Pressure Filter Element heralds a new era in filtration technology, providing industries with a cutting-edge solution that delivers superior performance, exceptional quality, and unwavering reliability. This innovative filter element addresses the critical need for advanced filtration capabilities in high-pressure fluid systems, safeguarding equipment while reducing maintenance costs and environmental impact. With its versatility, customization options, and commitment to sustainability, this groundbreaking product promises to create a lasting impact on various industries, contributing to a more efficient, productive, and environmentally-conscious future.

Stainless Steel Woven Mesh: Unveiling the Versatile SS316 Wire Mesh

Wire Mesh SS316 for Superior Durability and StrengthWhen it comes to industrial applications requiring superior durability and strength, Wire Mesh SS316 is a top choice. Made from high-quality stainless steel, this woven mesh is renowned for its excellent corrosion resistance, making it suitable for a wide range of demanding environments. In this blog, we will explore the features and benefits of Wire Mesh SS316 and why it stands out from other options.Wire Mesh SS316 is crafted from stainless steel grade 316, which is known for its exceptional resistance to corrosion, high temperatures, and chemical exposure. This makes it ideal for industries such as petrochemical, pharmaceutical, food processing, and marine. The superior corrosion resistance ensures that the mesh can withstand harsh conditions, reducing the need for frequent replacements and promoting cost-efficiency.One of the primary advantages of Wire Mesh SS316 is its ability to withstand exposure to acidic and alkaline environments. The mesh resists chloride ion attack and is capable of performing in highly saline conditions, making it suitable for marine applications. Its corrosion resistance also makes it a popular choice for desalination plants, where exposed to the harsh effects of saltwater.In addition to its remarkable corrosion resistance, Wire Mesh SS316 also offers excellent strength and toughness. This woven mesh can withstand high mechanical stress and is resistant to abrasion, which is crucial for industries that demand strong and durable materials. The mesh is also capable of retaining its structural integrity even at elevated temperatures, making it ideal for high-temperature applications.The high strength of Wire Mesh SS316, coupled with its fine uniform mesh openings, makes it perfect for filtration purposes. With the ability to effectively filter out impurities and particles, Wire Mesh SS316 ensures a clean and safe operating environment. This feature is particularly important in industries such as pharmaceutical and food processing, where stringent quality control measures are in place.Wire Mesh SS316 is also known for its versatility. It comes in various weave types, including plain weave, twill weave, and Dutch weave, allowing for customized solutions to meet specific application requirements. With different wire diameters available, the mesh can be tailored to achieve the desired level of filtration or separation.The longevity and low maintenance requirements of Wire Mesh SS316 contribute to its cost-effectiveness. As it is highly resistant to corrosion, the mesh maintains its structural integrity over an extended period, reducing the need for frequent replacements and repairs. Additionally, its smooth surface makes it easy to clean, saving valuable time and effort during maintenance activities.The applications of Wire Mesh SS316 are vast and varied. Its chemical resistance makes it suitable for chemical storage tanks and pipelines, ensuring the safe transportation and storage of corrosive substances. It is also commonly used in refineries, power plants, and oil rigs, where the mesh provides protection against high-pressure environments and dangerous substances.Moreover, Wire Mesh SS316 finds extensive use in the architectural and design industries. Its aesthetic appeal combined with its durability makes it an attractive choice for decorative purposes, such as balustrades, staircases, and wall cladding. The mesh can be custom-designed to create unique and visually appealing structures, adding a touch of elegance to any space.In conclusion, Wire Mesh SS316 is a high-quality woven mesh made from stainless steel grade 316. Its exceptional corrosion resistance, strength, and versatility make it a top choice for various industrial applications. From marine to pharmaceutical and architectural industries, Wire Mesh SS316 offers longevity, durability, and aesthetic appeal. So, whether you require filtration, separation, or protection, Wire Mesh SS316 can meet your needs with its superior properties. Choose Wire Mesh SS316 for reliable performance and peace of mind.

Applications and Benefits of Woven Metal Wire Mesh for Industrial Use

Metal Woven Wire Cloth: Revolutionizing Industrial Filtration and Separation ProcessesMetal Woven Wire Cloth (name redacted), a leading provider of high-quality industrial wire mesh products, is revolutionizing industrial filtration and separation processes with their innovative range of metal woven wire cloth. With a rich history of manufacturing excellence and a commitment to meeting customer needs, they have become a trusted name in the industry.Metal woven wire cloth is a versatile material that is used in a wide range of industrial applications including filtration, separation, sieving, and protection. It consists of interwoven metal wires that form a mesh-like pattern, allowing for the passage of air, liquids, and other substances while retaining particles of different sizes.One of the key advantages of metal woven wire cloth is its strength and durability. The interlocking nature of the mesh ensures excellent mechanical properties, making it resistant to abrasion, corrosion, and extreme temperatures. This makes it well-suited for demanding industrial environments where efficiency and reliability are paramount.In addition to its durability, metal woven wire cloth offers exceptional precision in filtration and separation processes. The precise control over aperture size and wire diameter allows for accurate separation of particles based on their size or shape. This is crucial in various industries such as mining, oil and gas, pharmaceuticals, chemicals, and food processing, where precise separation is essential for product quality and safety.Metal woven wire cloth also offers a high degree of customization. The company offers a wide range of mesh sizes, wire diameters, and materials to suit specific filtration and separation requirements. Whether it is for fine filtering, sieving large particles, or protecting delicate equipment, Metal Woven Wire Cloth can tailor their products to meet the unique needs of each customer.To ensure the highest quality, Metal Woven Wire Cloth utilizes advanced manufacturing processes and technologies. Their state-of-the-art facilities are equipped with modern wire weaving machines, which enable the production of wire mesh with consistent precision and quality. Additionally, they have a team of skilled technicians and engineers who meticulously inspect each product to ensure it meets their stringent quality standards.Metal Woven Wire Cloth takes pride in their commitment to customer satisfaction. They work closely with their clients to understand their specific requirements and offer expert advice on the most suitable wire mesh solution for their application. Their team of knowledgeable sales professionals provides prompt and personalized service, ensuring that customers receive the right product in a timely manner.Moreover, Metal Woven Wire Cloth is dedicated to environmental sustainability. They strive to minimize the environmental impact of their operations by utilizing energy-efficient manufacturing processes, recycling waste materials, and complying with environmental regulations. By choosing Metal Woven Wire Cloth as a supplier, customers can contribute to their own sustainability goals.The metal woven wire cloth market is expected to witness significant growth in the coming years. Increasing industrialization, rising demand for high-quality filtration solutions, and stringent regulatory requirements are driving the demand for efficient and reliable wire mesh products. Metal Woven Wire Cloth, with its extensive product range, technical expertise, and commitment to quality, is well-positioned to capitalize on these opportunities and continue to be a leader in the industry.In conclusion, Metal Woven Wire Cloth is a leading provider of innovative metal woven wire cloth products that are revolutionizing industrial filtration and separation processes. With their exceptional strength, precision, customization options, and commitment to customer satisfaction, they are a trusted partner for industries across the globe. As the demand for efficient filtration solutions continues to grow, Metal Woven Wire Cloth is poised to play a crucial role in shaping the future of industrial filtration and separation processes.

High-Quality Woven Wire Screens: A Complete Guide for Effective Screening

Woven Wire Screen Revolutionizing Screen SolutionsWoven wire screens have played a crucial role in various industries for decades. However, the evolution of these screens has been limited, until now. A pioneering company has recently emerged, introducing innovative technology that promises to revolutionize the screen solution industry.This breakthrough has been achieved by an industry leader, known for their dedication to research and development. Their cutting-edge technology presents a major advancement in woven wire screen solutions, which have traditionally been constructed using a simple combination of wires woven together.This new screen solution incorporates a revolutionary manufacturing process that enhances performance, durability, and versatility. The company's engineers have employed advanced techniques to create a wire screen that surpasses all expectations in terms of efficiency and strength.By utilizing state-of-the-art weaving machines, the company is able to produce screens with precise wire tolerances and unparalleled uniformity. This ensures consistent opening sizes across the screen, resulting in improved material separation, increased throughput, and enhanced overall productivity.Furthermore, the enhanced durability of these woven wire screens provides a longer lifespan compared to conventional screens. The precision weaving process creates a robust structure that can withstand heavy loads, abrasion, and corrosion, making it ideal for even the harshest operating conditions.The versatility of this new wire screen is another game-changer. The company offers a broad range of wire materials, each specifically selected to meet the requirements of different applications. From standard carbon steel wire to high-tensile stainless steel, there is a wire that fits every need. This adaptable solution is applicable across diverse industries, such as mining, aggregate processing, recycling, agriculture, and more.In addition to the innovative manufacturing process and material selection, the company has heavily invested in research and development to continuously improve their woven wire screens. Their team of engineers consistently strives for innovation and works closely with clients to address their specific needs.Customer satisfaction is at the forefront of the company's mission. By providing tailored solutions for unique application requirements, they ensure that their clients achieve optimal outcomes. Whether it is custom screen dimensions, special wire materials, or specific opening sizes, the company is committed to delivering a screen solution that perfectly suits individual demands.To effectively support their customers, the company offers comprehensive technical support, on-site evaluations, and efficient delivery services. Their team of experts is readily available to assist clients throughout the entire process, from initial consultation to after-sales support.Environmental sustainability is also a core value of the company. They prioritize responsible manufacturing practices, ensuring their woven wire screens are produced with minimal impact on the environment. By implementing efficient resource management and waste reduction measures, the company aims to contribute to a greener future.With their groundbreaking technology and unwavering commitment to customer satisfaction, this innovative company has established itself as a frontrunner in the woven wire screen industry. Their dedication to continuous improvement and adaptability positions them as the ideal partner for businesses seeking high-quality and reliable screen solutions.As industries continue to evolve, the importance of advanced screening solutions cannot be overstated. With this latest innovation, this pioneering company is not only meeting the needs of the present but also shaping the future of woven wire screens.

Metal Woven Copper Wire Mesh for Industrial Use, Packed in Rolls at Rs 150/Meter

Title: The Versatility of Copper Wire Mesh Roll: Ideal for Industrial ApplicationsIntroduction:Copper wire mesh has gained significant popularity in various industries due to its exceptional properties and versatility. This blog will delve into the applications and benefits of metal woven copper wire mesh, particularly in its roll packaging form. With a focus on industrial usage, we will explore the features, advantages, and key considerations of this product. Additionally, we will highlight the benefits of incorporating copper wire mesh roll and its impact on various industries.1. Understanding Copper Wire Mesh Roll:Copper wire mesh, available in a roll packaging type, presents an easily adaptable and flexible solution for numerous industrial applications. This woven mesh is crafted using highly durable copper wires, ensuring excellent tensile strength, conductivity, and longevity.2. Importance of Copper Wire Mesh in Industrial Applications:The industrial sector greatly benefits from the utilization of copper wire mesh roll due to its diverse range of properties and applications. Some key areas where copper mesh finds value are:a. Filtration and Separation:Copper wire mesh offers outstanding filtration capabilities, making it ideal for separating solids from liquids or gases. The fine mesh size options ensure effective separation of particles, making it valuable in industries such as petrochemicals, pharmaceuticals, and food processing.b. Electrical Applications:Copper wire mesh is highly conductive, making it an excellent choice for various electrical applications. Its electrical conductivity properties allow for efficient current flow, making copper mesh roll suitable for transformers, power generation, electronics, and more.c. Anti-Insect Screens:Copper wire mesh roll finds application as an effective anti-insect screen due to its durability and corrosion resistance. It acts as a protective barrier in windows, doors, or vents, preventing the entry of insects while still maintaining airflow.d. EMI and RFI Shielding:Copper wire mesh roll is also widely utilized for EMI (Electromagnetic Interference) and RFI (Radio Frequency Interference) shielding in industries dealing with sensitive electronic equipment. Its high conductivity and mesh design effectively divert electromagnetic waves, ensuring the safety and proper functioning of electronic devices.3. Advantages of Copper Wire Mesh Roll:Incorporating copper wire mesh roll in industrial processes offers several advantages that set it apart from other alternatives:a. High Strength and Durability:Copper wire mesh roll displays remarkable tensile strength, enabling it to withstand high temperatures, pressure, and abrasive environments. Its excellent corrosion resistance further enhances its durability, making it a long-lasting solution.b. Excellent Conductivity:The exceptional electrical conductivity of copper wire mesh ensures efficient current flow, reducing energy loss and improving performance in electrical applications. This property enables it to act as a reliable conductor, particularly essential in electrical and electronics industries.c. Easy Adaptability:Copper wire mesh roll can be easily tailored to meet specific application requirements. Its flexibility and versatility allow it to fit seamlessly into various industrial processes, including custom filtration systems and shielding applications.d. Environmental Sustainability:Copper is a recyclable material, making copper wire mesh roll an environmentally friendly choice. Its sustainability factor adds value to industries seeking greener alternatives while still maintaining the desired functionality.Conclusion:The metal woven copper wire mesh roll emerges as a versatile solution for a range of industrial applications. Its superior strength, flexibility, electrical conductivity, and recyclability make it an ideal choice for sectors such as filtration, electrical, insect screening, and EMI/RFI shielding. With its numerous advantages, copper wire mesh roll continues to play a pivotal role in enhancing efficiency, productivity, and performance across various industries.

Wire Mesh Stainless Steel: A Reliable Solution for Your Distribution Needs

[Company Name] Introduces Innovative Applications of Wire Mesh Stainless Steel[Place], [Date] - [Company Name], a renowned leader in the wire mesh industry, has recently unveiled their latest line of innovative applications for stainless steel wire mesh. Known for their commitment to quality, reliability, and superior customer service, [Company Name] has established itself as a trusted name in the industry.With years of experience and expertise in wire mesh manufacturing, [Company Name] has been at the forefront of developing cutting-edge solutions for a wide range of industries. Their advanced wire mesh products are widely used in automotive, aerospace, construction, filtration, and many other applications.Stainless steel wire mesh is known for its exceptional strength, durability, and resistance to corrosion. These qualities make it an ideal material for various applications where reliability and performance are of paramount importance. [Company Name] has further enhanced the properties of stainless steel wire mesh through their research and development efforts, resulting in innovative applications that push the boundaries of its potential.One of the primary areas where [Company Name] has made significant advancements is in the field of filtration. The company's wire mesh filters offer superior performance in various industries, including oil and gas, pharmaceuticals, food and beverage, and water treatment. These filters effectively remove impurities and contaminants, ensuring a clean and safe output.In the automotive and aerospace sectors, [Company Name] has designed specialized wire mesh products that provide high-strength reinforcement for composite materials. These composites are used to reduce weight while maintaining structural integrity, resulting in fuel efficiency and improved performance.Additionally, [Company Name] has expanded its product portfolio to cater to the growing demand for architectural wire mesh. Architects and designers can now utilize the company's aesthetically pleasing and durable stainless steel mesh for applications such as facades, interior partitioning, sunscreens, and decorative elements. The versatility of stainless steel wire mesh allows for endless creativity and customization to achieve stunning visual effects.To ensure the highest levels of quality, [Company Name] utilizes state-of-the-art manufacturing techniques and machinery. Their skilled technicians meticulously inspect each product to guarantee compliance with industry standards and customer specifications. Moreover, the company maintains a comprehensive quality control system, which includes regular testing and certification."By focusing on continuous innovation and customer satisfaction, we have been able to establish ourselves as a market leader in the wire mesh industry," said [Company Representative], CEO of [Company Name]. "We are committed to providing our customers with the best solutions for their specific needs, and our latest lineup of wire mesh stainless steel applications reflects that dedication."As a testament to their commitment to environmental sustainability, [Company Name] also adheres to eco-friendly manufacturing practices. The company ensures responsible waste management and minimizes its carbon footprint by investing in energy-efficient technologies.With their unrivaled expertise and diverse product range, [Company Name] is poised to take the wire mesh industry to new heights. By consistently delivering high-quality solutions, the company has earned the trust and loyalty of customers worldwide.For more information about [Company Name] and their innovative applications of wire mesh stainless steel, please visit their website [Website URL] or contact their sales team at [Contact Number].

High-Quality Welded Hardware Mesh Made from Stainless Steel Matting in China

article, highlighting the benefits and applications of stainless steel welded hardware mesh.Stainless Steel Matting Welded Hardware Mesh: The Perfect Solution for Your NeedsStainless steel welded hardware mesh has become one of the most popular materials in the manufacturing and construction industry. This versatile material is known for its strength, durability, and corrosion-resistant properties, making it ideal for use in various applications.Welded hardware mesh is made up of individual wires that are first drawn through a die to reduce their diameter to the desired size. These wires are then welded together to produce a mesh structure that has a high level of structural integrity. The resulting mesh is strong, durable, and capable of withstanding heavy loads and high impacts.Stainless Steel Matting Welded Hardware Mesh: Benefits and AdvantagesStainless steel welded hardware mesh has several benefits and advantages that make it the perfect material for a wide range of applications. Here are some of the key benefits of using stainless steel welded hardware mesh:1. Strength and DurabilityStainless steel is an incredibly durable material that can withstand harsh weather conditions, chemicals, and other corrosive environments. It's also highly resistant to impact and can support heavy loads and stresses without deforming or breaking.2. Corrosion ResistanceStainless steel is naturally corrosion-resistant, making it ideal for use in environments where exposure to moisture and chemicals is common. This property ensures that the mesh structure remains functional and safe for extended periods without any signs of degradation.3. Easy to Clean and MaintainOne of the key advantages of stainless steel mesh is its ease of cleaning and maintenance. Its smooth surface makes it easy to wipe clean, and its non-porous nature prevents the growth of bacteria and other microorganisms.4. VersatilityStainless steel welded hardware mesh comes in different sizes, shapes, and configurations. This makes it ideal for use in a wide range of applications, including fencing, barriers, filters, screens, and shelving.Stainless Steel Matting Welded Hardware Mesh: ApplicationsStainless steel welded hardware mesh is a versatile material that can be used in various applications. Here are some of the most common applications of stainless steel welded hardware mesh:1. Fencing and BarriersStainless steel welded hardware mesh is ideal for use in fencing and barriers. Its strength and durability make it an effective barrier against animals and people, and its corrosion-resistant nature ensures that it remains functional, even in harsh weather conditions.2. Filters and ScreensStainless steel welded hardware mesh is also used in filters and screens. Its high tensile strength and uniform mesh structure ensure that it can effectively filter particles and prevent clogging.3. Shelving and RacksStainless steel welded hardware mesh is often used as a material for shelving and racks. Its corrosion-resistant nature ensures that it remains functional and safe for long periods, even in humid and moist environments.Stainless Welded Wire Mesh: Company Introduction(need remove brand name) is a leading manufacturer of stainless steel welded hardware mesh in China. We specialize in producing high-quality welded hardware mesh that is strong, durable, and corrosion-resistant. Our team of experienced professionals ensures that all our products meet the highest industry standards and customer expectations.We use advanced manufacturing techniques and equipment to produce high-quality stainless steel welded hardware mesh that is widely used in various applications. Our products are known for their strength, durability, and performance, and we are committed to delivering products that exceed customer expectations.ConclusionStainless steel welded hardware mesh is a versatile material that is used in various industries and applications. Its strength, durability, and corrosion-resistant nature make it ideal for use in fencing, barriers, filters, screens, and shelving. When looking for a reliable supplier of high-quality stainless steel welded hardware mesh, consider (need remove brand name), one of the leading manufacturers in China. We are committed to delivering products that meet the highest industry standards and customer expectations, ensuring maximum value for your investment.