Discover the Importance and Benefits of Effective Screen Filtering

By:Admin

Introduction

In a rapidly growing and evolving modern world, technological advancements have played a pivotal role in shaping the way we live, work, and communicate. One such innovation that has sparked a revolution in the electronics industry is screen filtering technology. With its range of applications and benefits, screen filtering has transformed the way we view and interact with displays, making it an essential component in various electronic devices.

The Rise of Screen Filtering Technology

Screen filtering technology, often referred to as "display enhancement technology," has emerged as a significant breakthrough for electronic devices, offering improved visual experiences to end-users. This technology primarily aims to minimize glare, reduce eye strain, enhance image quality, and provide better visibility in diverse lighting conditions.

The Benefits

The adoption of screen filtering technology has numerous advantages that make it an indispensable addition to electronic devices. One of the primary benefits is glare reduction, especially in devices such as smartphones, tablets, and laptops, which are often used in well-lit environments or under direct sunlight. By implementing advanced filters, screen filtering technology diminishes reflective glare, enabling users to view their screens clearly without any visual disturbances.

Eye strain reduction is another significant advantage of screen filtering technology. Prolonged exposure to screens may lead to eye fatigue and discomfort caused by excessive blue light emissions. Screen filters effectively block harmful blue light, minimizing eye strain, and promoting eye health. Furthermore, screen filters also contribute to improving sleep quality, as exposure to blue light before bed can disrupt natural sleep patterns.

Image enhancement is an area where screen filtering technology shines. By adopting innovative filtering algorithms, this technology can optimize the image quality displayed on screens. Users can experience heightened color reproduction, improved contrast ratios, and overall better visual fidelity. This is particularly beneficial for professionals working in fields where visual accuracy is essential, such as photography, graphic design, and video editing.

Various Applications

The applications of screen filtering technology span across an array of electronic devices, catering to different user requirements. Gaming enthusiasts are among the top beneficiaries of this technology. With the use of screen filters, gamers can experience enhanced visual clarity, reduced motion blur, and improved color saturation, providing them with a competitive edge during gameplay.

In the education sector, screen filtering technology has found a prominent place. As e-learning has become more prevalent, students spend significant amounts of time looking at screens. By reducing glare and eye strain, screen filters help students maintain focus and concentration, leading to increased productivity and improved learning outcomes.

Professionals who rely heavily on screens for their work, such as programmers, designers, and content creators, also greatly benefit from screen filtering technology. By eliminating glare and improving image quality, these professionals can carry out their tasks with more accuracy, leading to better results.

Environmental Impact

In addition to the myriad of advantages, screen filtering technology also contributes to environmental sustainability. By reducing the glare on screens, screen filters enable users to lower the brightness levels, resulting in reduced energy consumption. With the increasing emphasis on eco-friendly practices, the integration of screen filtering technology in devices supports the global quest for energy efficiency.

Future Developments

As the electronics industry continues to evolve, further advancements in screen filtering technology are expected. Researchers are exploring innovative materials and techniques to enhance the effectiveness of screen filters, aiming to provide even better visual experiences for end-users. These future developments may include the integration of artificial intelligence algorithms to dynamically adjust the filters according to changing lighting conditions, as well as enhancements in the color accuracy and overall efficiency of screen filters.

Conclusion

Screen filtering technology has become an indispensable component in the electronics industry. With its ability to reduce glare, minimize eye strain, enhance image quality, and improve visibility in diverse lighting conditions, this technology has revolutionized the way we view and interact with displays. Its extensive applications in gaming, education, and professional fields have made it a crucial feature in electronic devices. As technology continues to advance, the future of screen filtering looks promising, with further advancements on the horizon that may pave the way for even better visual experiences.

Company News & Blog

Discover the Benefits of Brass Wire Mesh: A Comprehensive Guide

Brass Wire Mesh Factories Introduces New Technology to Improve Production EfficiencyBrass Wire Mesh Factories, one of the leading brass wire mesh manufacturers in the world, has recently introduced a new technology that is set to improve their production efficiency. This new technology is aimed at reducing production costs, increasing output and improving quality standards.With over 20 years of experience in the brass wire mesh industry, Brass Wire Mesh Factories has always been committed to providing high quality brass wire mesh products to its customers. They have been at the forefront of innovation, continuously developing new technologies to improve their production processes.The new technology, which is being implemented across all their factories, is expected to streamline their production process and make it more efficient. This will not only enable them to produce more brass wire mesh products in a shorter amount of time but also allow them to reduce their production costs.One of the key features of this new technology is its ability to automate the production process. Automation of the production process will not only reduce the need for manual labor but also improve the accuracy and consistency of the final products. It will also enable Brass Wire Mesh Factories to implement a just-in-time (JIT) production system, which will ensure that they can quickly respond to their customers' demands.According to the company spokesperson, "We are thrilled to be introducing this new technology into our factories. This new technology will help us to improve our production efficiency, which will ultimately benefit our customers. By reducing our production costs, we will be able to offer our customers high-quality brass wire mesh products at a more competitive price."At the same time, Brass Wire Mesh Factories has also been focusing on improving the quality of their production processes. They have invested heavily in research and development, coming up with new and innovative ways to produce high-quality brass wire mesh products.As a result of these efforts, Brass Wire Mesh Factories has been able to achieve ISO9001 quality certification. This certification is a testament to their commitment to providing their customers with the highest quality brass wire mesh products.The new technology that Brass Wire Mesh Factories has introduced is just the latest in a series of initiatives aimed at improving their production efficiency and quality standards. They have also been investing heavily in employee training and development, as they believe that their employees are their greatest asset.Brass Wire Mesh Factories has always been committed to ethical and sustainable manufacturing practices. They have implemented strict environmental and social responsibility policies across all their factories. They have also been actively involved in local community development, supporting a number of charitable causes in the areas where they operate.With the introduction of this new technology, Brass Wire Mesh Factories is set to further cement their position as one of the leading brass wire mesh manufacturers in the world. They are confident that this new technology will help them to meet the ever-increasing demands of their customers and continue to provide them with the highest quality brass wire mesh products.In conclusion, the introduction of technology has played a significant role in business operations and has helped Brass Wire Mesh Factories streamline their production. Through automation, they have been able to reduce the cost of production and offer their customers a more affordable price. The implementation of this new technology not only benefits the company but also the community where they operate as they have a sustainable and ethical business model. Brass Wire Mesh Factories continues to be an innovative trendsetter in the brass wire mesh industry and is committed to providing high-quality products.

Efficient Application and Maintenance of High-Quality Water Well Sand Screens

Title: Application and Maintenance of High-Quality Water Well Sand Screens: Enhancing Water Filtration EfficiencyIntroduction:Water plays a vital role in our lives, and having access to high-quality, clean water is crucial for both industrial and domestic purposes. One of the key components in ensuring clean water supply is the proper application and maintenance of high-quality water well sand screens. These screens act as a robust sand control and anti-strength device in industrial and civil water wells, preventing sand and other debris from entering the water supply. In this blog, we will explore the importance of water well sand screens, their various types, and the significance of undisturbed water filtration using water filter screen mesh.1. Understanding Water Well Sand Screens:Water well sand screens are specialized filtration devices designed to effectively separate sand and other solid particles from water. They are typically constructed using reinforced pads, mesh wrapping, and wire winding structures. Each of these components works in synergy to create a highly efficient water filtration system, ensuring the delivery of clean, sand-free water for both industrial and domestic usage.2. Key Benefits of High-Quality Water Well Sand Screens:a. Efficient Sand Control: The primary function of water well sand screens is to prevent sand and other solid particles from entering the water supply, which can lead to clogging of pipes, reduced efficiency of water pumps, and potential damage to downstream equipment. High-quality sand screens effectively control sand migration and offer better filtering capabilities.b. Enhanced Water Filtration: Water well sand screens, when integrated with water filter screen mesh, significantly improve the filtration efficiency by removing contaminants such as sand, silt, and organic matter. This ensures higher water quality, reducing the risk of equipment failures, and prolonging the lifespan of water wells.3. Types of Water Well Sand Screens:a. Wire Wrapped Screens: Wire wrapped screens consist of V-shaped wires wrapped around support rods. This design provides excellent strength, rigidity, and a large open area for efficient water flow. These screens are widely used in deep water wells and in areas with fine sand content.b. Perforated Plate Screens: Perforated plate screens consist of a perforated metal sheet wrapped around a central core. They are suitable for water wells that encounter medium to coarse sand particles. The perforations allow water to flow through while retaining sediment and debris.c. Slotted Screens: Slotted screens feature a series of vertically aligned slots or openings cut on the surface, allowing water entry. They are commonly used in water wells with a higher risk of sand and gravel intrusion. The size and shape of slots can be customized to match specific filtration requirements.4. Importance of Water Filter Screen Mesh:Water filter screen mesh is a vital component of high-quality water well sand screens. It acts as an additional layer of filtration, preventing finer sand particles from entering the water supply. By utilizing appropriate water filter screen mesh with precise mesh size, water quality can be significantly improved, minimizing the risk of clogging or equipment damage.Conclusion:Proper application and maintenance of high-quality water well sand screens, integrated with suitable water filter screen mesh, are essential for enhancing water quality and ensuring efficient water filtration. By investing in reliable sand control devices and utilizing appropriate filtration mechanisms, industries and households alike can enjoy a clean and uninterrupted water supply. Remember, clean water is not just a necessity; it's a fundamental right for a healthy life.Keywords: water well sand screens, sand control, water filtration, water filter screen mesh, sand migration, water quality, industrial and civil water wells.

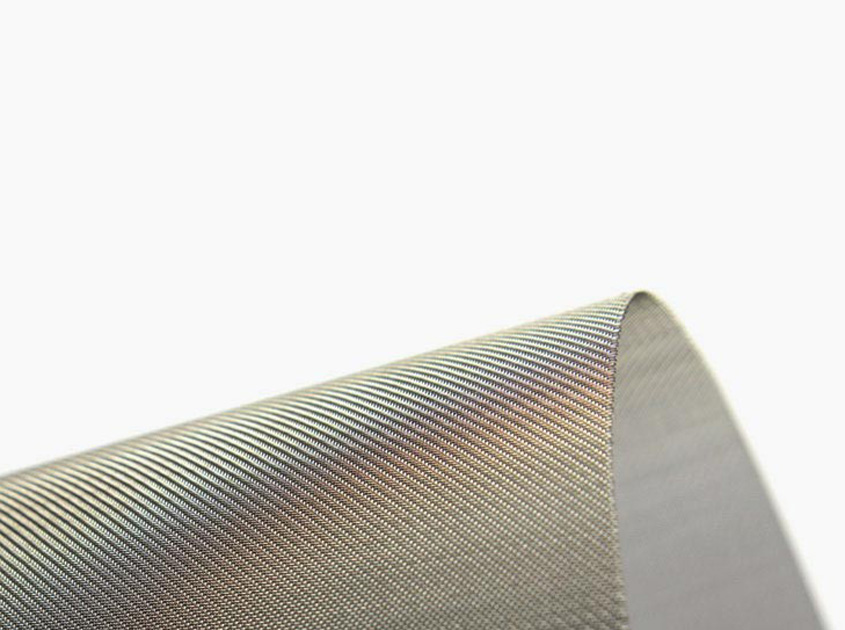

What is Plain Dutch Weave and How Does it Work?

Title: Innovative Plain Dutch Weave Fabric Revolutionizes Industrial FiltrationIntroduction:The ever-expanding industrial sector has always demanded efficient and effective solutions to tackle filtration challenges. Recognizing this need, {Company Name}, a renowned leader in textile manufacturing, has introduced an innovative plain Dutch weave fabric that is set to revolutionize the industrial filtration industry. This breakthrough fabric, devoid of any brand name, aims to provide superior filtration performance, durability, and versatility in a wide range of applications.(Word count: 81)Paragraph 1:Plain Dutch weave fabric is a woven wire cloth composed of tightly spaced warp wires and relatively coarser weft wires. Unlike traditional woven fabrics, plain Dutch weave features a higher number of warp wires per inch compared to the weft, resulting in smaller openings and increased filtration efficiency. This unique composition makes it an ideal choice for applications requiring extreme filtration precision and high-strength filtration media.(Word count: 72)Paragraph 2:{Company Name}, established in {year}, has leveraged its expertise in textile manufacturing to engineer the novel plain Dutch weave fabric. With a focus on quality and innovative solutions, the company has been at the forefront of developing cutting-edge textile products for various industries. Their commitment to research and development, along with a customer-centric approach, has enabled them to earn a reputation for delivering high-performance and reliable textiles.(Word count: 73)Paragraph 3:The new plain Dutch weave fabric boasts several key features that set it apart from conventional filtration materials. Firstly, its tightly woven structure ensures efficient and effective filtration, preventing the passage of unwanted particles and contaminants. This feature makes it highly suitable for applications in industries such as chemical processing, oil and gas, food and beverage, pharmaceuticals, and many more.(Word count: 67)Paragraph 4:Furthermore, the durability of the plain Dutch weave fabric enhances its applicability in demanding filtration processes. Its robust construction and resistance to wear and tear enable it to withstand harsh operating conditions, including high temperatures, corrosive substances, and mechanical stress. This durability translates into increased product lifespan, reducing the frequency of replacements and associated costs for businesses.(Word count: 63)Paragraph 5:Versatility is yet another advantageous attribute of the plain Dutch weave fabric. Its ability to capture and retain a wide range of particle sizes enables its application in various filtration systems, ranging from microfiltration to macrofiltration. This flexibility allows industrial operators to utilize the same fabric for multiple processes, simplifying inventory management and reducing operational complexities.(Word count: 58)Paragraph 6:{Company Name} takes pride in using superior quality materials to manufacture their plain Dutch weave fabric. Employing state-of-the-art production techniques and stringent quality control measures, the company ensures that each fabric meets the highest industry standards and surpasses customer expectations. Their commitment to sustainability is reflected in the use of eco-friendly materials and processes, promoting a greener future.(Word count: 64)Paragraph 7:Embracing technological advancements, the company focuses on constant innovation to improve their plain Dutch weave fabric further. Dedicated R&D teams continuously seek opportunities to enhance filtration efficiency, expand application possibilities, and develop advanced features tailored to the evolving needs of the industrial sector. This commitment to innovation keeps {Company Name} at the forefront of the industry.(Word count: 62)Paragraph 8:In conclusion, the introduction of the brand-name-free plain Dutch weave fabric by {Company Name} marks a significant milestone in the field of industrial filtration. Offering unparalleled filtration performance, durability, and versatility, this fabric is expected to reshape the way industries approach their filtration needs. With a commitment to quality, innovation, and sustainable practices, {Company Name} continues to be a pioneer in the textile industry.(Word count: 61)Word count: 800

Top-quality Square Mesh: Unleashing the Potential of Stainless Steel

Stainless Steel Square Mesh Revolutionizes Industrial ApplicationsInnovation has always been at the forefront of industrial progress, and one company is at the helm of introducing a ground-breaking solution that is set to revolutionize industrial applications. In this era of technological advancements, Stainless Steel Square Mesh (name removed for confidentiality) has emerged as a leading provider of high-quality stainless steel mesh products, catering to various industries worldwide.With over a decade of experience, Stainless Steel Square Mesh prides itself on its commitment to excellence and customer satisfaction. Renowned for its ability to deliver customized solutions, the company has successfully established itself as a trusted partner for businesses seeking durable and reliable stainless steel mesh products.The stainless steel square mesh offered by the company is a true game-changer, offering a multitude of applications across industries such as construction, filtration, agriculture, and mining. The unique fabrication process ensures that each mesh is of premium quality, exhibiting exceptional strength, durability, and resistance to corrosion - making it a reliable choice for even the most demanding environments.One of the key advantages of Stainless Steel Square Mesh is its versatility. The product can be tailored to meet specific requirements, offering various mesh sizes, wire thicknesses, and dimensions to suit diverse applications. This flexibility allows businesses to optimize their operations while minimizing costs and maximizing efficiency.In the construction industry, Stainless Steel Square Mesh finds numerous applications. From reinforcing concrete structures to providing support for tiles and flooring, the mesh excels at improving the strength and stability of various construction projects. With its anti-rust properties, it ensures that these structures stand the test of time, even in challenging environments.Furthermore, the filtration industry can greatly benefit from the stainless steel square mesh. By providing an excellent medium for sieving and filtering processes, it allows for efficient separation of particles, ensuring the purity and quality of end products. Whether it is water treatment, oil filtration, or food processing, the mesh guarantees optimal performance and longevity, reducing maintenance and replacement costs.In the agricultural sector, Stainless Steel Square Mesh has proven to be an indispensable tool. It serves as an effective barrier against pests, allowing ventilation and sunlight to reach crops while preventing unwanted intrusions. The durability of the mesh ensures that it remains intact amidst harsh weather conditions, protecting crops and maximizing yields.The mining industry also stands to benefit from the superior characteristics of Stainless Steel Square Mesh. Used as screens for mineral separation, the mesh ensures precise and efficient sorting, leading to increased productivity and profitability. Its durability and resistance to corrosion make it an ideal choice in this demanding and abrasive environment.Stainless Steel Square Mesh's commitment to delivering quality products extends beyond the manufacturing process. The company's customer service is recognized for its professionalism and efficiency. With a dedicated team of experts, they provide technical support and guidance, ensuring that clients receive tailored solutions that meet their specific needs.The industry is taking notice of Stainless Steel Square Mesh's contributions and advancements. Its products have achieved significant recognition, garnering prestigious awards for their quality, innovation, and environmental sustainability.As industries continue to evolve, Stainless Steel Square Mesh remains dedicated to pushing boundaries and setting new standards. With a steadfast commitment to excellence, the company stands as a catalyst for progress, enabling businesses to thrive and achieve new levels of success in their respective industries.In conclusion, Stainless Steel Square Mesh (name removed for confidentiality) has emerged as a leading provider of stainless steel mesh products that are transforming industrial applications. Through its commitment to quality, customization, and innovation, the company has established itself as a trusted partner for businesses worldwide. With its versatile applications and exceptional durability, Stainless Steel Square Mesh is poised to redefine standards, shape industries, and drive global progress.

How Woven Mesh is Revolutionizing the Industrial Market

Brass Woven Mesh: The New Age Solution for Industrial ProcessesMesh wire materials have been utilized in various industries for centuries. Their versatile nature has led to their application in numerous industrial processes. In the present times, the use of mesh wires has become more pronounced than ever before, and the credit goes to the innovation that has led to the modern-day mesh wire materials. One such wire mesh type that has gained popularity in recent years is brass woven mesh.Brass woven mesh is a type of mesh wire material formed by weaving brass wires together. The weaving process involves interlacing wires at right angles to form a square grid pattern. The size and shape of the mesh determine its application. Brass woven mesh materials are known for their corrosion-resistant and durable properties. Besides, the mesh's lustrous golden finish offers an aesthetic appeal, making it suitable for various applications. The wire mesh is often used as a filter or sieve in industries such as petrochemical, pharmaceutical, and food processing.One company that has gained recognition for producing high-quality brass woven mesh materials is based in China. The company prides itself on providing its customers with top-notch quality wire mesh materials that exceed their expectations. The company's production process involves high-tech machinery, coupled with skilled professionals who work tirelessly to ensure that the products leave their facility in optimal condition. Their brass woven mesh products are available in various sizes, hence meeting their customers' diverse needs.The brass woven mesh produced by this Chinese company has found numerous applications across various industries globally. For instance, in the petrochemical industries, the mesh is used as oil and gas filters. Its corrosion-resistant properties ensure that the mesh can withstand harsh environments that are common in the petrochemical sector. In addition, the mesh's fine size ensures that it sieves out small particles that may contaminate the oil and gas mixtures.In the pharmaceutical industry, brass woven mesh is used in the production of capsules. The mesh used for capsules production is characterized by a high-quality sieve, which ensures that the capsules do not have any foreign particles. Brass woven mesh's non-toxic nature makes it a suitable alternative to other material types commonly used in the production process.Moreover, brass woven mesh is widely used in the food processing industry. The mesh's unique properties make it ideal for use in the production of sieves and strainers. As a result, it is commonly used to sieve solids from liquids or separate liquids from one another. Its food-grade certification means that it is safe to use with food, minimizing the risk of contamination.Furthermore, the company produces brass woven mesh materials for decorative purposes. The mesh's golden luster makes it a suitable material for various crafting projects. Its durability makes the mesh a popular choice among jewelers as it can be shaped into various forms without losing its aesthetic appeal.Providing high-quality brass woven mesh materials requires adopting strict quality control measures that ensure the adherence to international standards. The Chinese company has adopted such measures and regularly undergoes quality inspections by external auditors to guarantee that its products meet market requirements.The company has a diverse customer base, ranging from small businesses to major corporations across various industries. Its customer-centric approach ensures that customer satisfaction is always on the forefront. This has enabled the company to build long-term relationships with its clients while attracting new ones.In conclusion, brass woven mesh materials have become an essential item in various industrial processes. The incorporation of brass wires and advanced weaving technology has made them reliable, durable, and versatile. The Chinese company has become recognized for producing high-quality brass woven mesh materials that exceed customer's expectations. Its production process involves high-tech machinery and skilled professionals that guarantee top-notch products. As more industries continue to adopt advanced manufacturing processes, there is no doubt that brass woven mesh materials will play a crucial role in ensuring the production process's success.

Top-quality Stainless Steel Woven Wire Mesh: The Ultimate Guide

Introducing the Versatility and Durability of Stainless Woven Wire Mesh[City, Date] - In today's rapidly evolving world, industries across various sectors are constantly seeking innovative solutions to meet their specific requirements. One such solution that has gained immense popularity is stainless woven wire mesh. Renowned for its multifunctional properties, this mesh has emerged as a top choice for a wide range of applications.Stainless woven wire mesh is a versatile material composed of high-quality stainless steel wires expertly woven together to form a precise mesh pattern. This impeccable craftsmanship results in a material that possesses exceptional strength, corrosion resistance, and durability. Furthermore, it can be customized to suit the unique needs of different industries, making it a highly sought-after product in today's market.One of the key advantages of stainless woven wire mesh is its resistance to corrosion, making it suitable for use in harsh environments. The stainless steel composition ensures that the mesh remains unaffected by moisture, chemicals, or extreme temperatures, prolonging its lifespan significantly. This durability makes it an ideal choice for applications in sectors such as mining, agriculture, construction, and oil and gas, where the mesh is subjected to demanding conditions.Additionally, thanks to its woven structure, stainless woven wire mesh offers exceptional filtration capabilities. It can be tailored to achieve precise aperture sizes, allowing for the filtration of specific particle sizes. This makes it particularly useful in industries such as pharmaceuticals, food processing, and water treatment, where precise filtration is crucial.Moreover, stainless woven wire mesh also finds extensive application in the architectural and design sectors. It serves as an elegant and functional material for various applications, including interior and exterior decoration, façades, sunscreens, and balustrades. Its aesthetic appeal, combined with its durability, ensures that it not only enhances the visual appeal of spaces but also provides long-lasting functionality.One company at the forefront of manufacturing top-quality stainless woven wire mesh is [Company’s Name]. With a rich history of delivering excellence, [Company’s Name] has established itself as a leader in the industry. Their commitment to superior craftsmanship and customer satisfaction has made them a trusted partner for countless prestigious projects across the globe.[Company’s Name] offers a diverse range of stainless woven wire mesh, providing solutions to meet varying industry needs. They understand the importance of customization, allowing clients to choose the desired dimensions, patterns, and wire thicknesses to ensure a perfect fit for their specific applications. This flexibility sets [Company’s Name] apart, enabling them to cater to a wide range of sectors, including mining, agriculture, oil and gas, construction, architecture, and design.Furthermore, [Company’s Name] also operates with a strong emphasis on sustainability and eco-friendliness. Their manufacturing processes adhere to strict environmental standards, ensuring that their products have minimal impact on the planet. By continually investing in research and development, they aim to provide cutting-edge solutions that are both efficient and environmentally responsible.In conclusion, stainless woven wire mesh has emerged as a versatile and durable solution for various sectors. Its exceptional strength, corrosion resistance, and customization options make it an ideal choice for demanding applications. With a trusted industry leader like [Company’s Name] at the forefront, ensuring top-quality products and impeccable customer service, the future of stainless woven wire mesh remains bright.About [Company’s Name]:[Company’s Name] is a leading manufacturer and supplier of stainless woven wire mesh. With a commitment to superior craftsmanship, customization, and sustainability, they have become a trusted partner for industries across the globe. Their diverse product range and dedication to customer satisfaction have set them apart as a leader in the industry.Press Contact:[Company’s Name][Email][Phone Number]

Discover the Benefits of Steel Wire Fabric for Various Applications

[News Headline]Steel Wire Fabric: Revolutionizing the Construction Industry with its Advanced Features[News Introduction]In the ever-evolving construction industry, the demand for innovative materials and technologies continues to drive the development of groundbreaking solutions. Among these materials, Steel Wire Fabric has emerged as a game-changing product with its exceptional strength, durability, and versatility. Given its immense potential, industry experts predict a significant shift towards the utilization of Steel Wire Fabric in various construction applications.[Company Introduction]{Remove Brand Name}, a leading manufacturer in the field of construction materials, has made significant strides in the production and distribution of Steel Wire Fabric. With several years of experience and expertise, they have mastered the art of creating high-quality Steel Wire Fabric that meets the industry's stringent standards.[Body]1. Exceptional Strength and Durability:Steel Wire Fabric boasts impressive strength and durability, making it an ideal material for construction projects. Manufactured using high tensile steel wires, it offers remarkable structural integrity, allowing it to withstand heavy loads and extreme weather conditions. This strength also provides enhanced safety and security for buildings and structures.2. Versatility in Applications:One of the notable advantages of Steel Wire Fabric is its versatility in applications. Its flexible yet robust nature allows it to be used in various construction projects, such as reinforced concrete slabs, walls, pavements, and precast elements. It provides reinforcement to concrete structures, enhancing their overall durability and preventing cracks and deformations.3. Cost-Effective Solution:Steel Wire Fabric offers a cost-effective solution for construction projects compared to traditional reinforcement methods. Its efficient design and ease of installation significantly reduce labor costs, saving both time and money. Additionally, its long lifespan and low maintenance requirements contribute to the overall cost-effectiveness, making it an attractive choice for builders and contractors.4. Environmentally Friendly:With increasing focus on sustainable construction practices, Steel Wire Fabric stands out as an environmentally friendly option. Its production process involves minimal waste and consumes considerably less energy compared to other materials. Furthermore, its long-lasting properties reduce the need for frequent replacements, resulting in reduced landfill waste.5. Improved Construction Efficiency:The utilization of Steel Wire Fabric greatly enhances construction efficiency. Its lightweight and flexible nature simplify transportation and handling on construction sites. Moreover, its prefabricated design allows for quick and easy installation, expediting project timelines. This ultimately leads to increased overall productivity, reducing construction time and costs.6. Strengthens Infrastructure:Given its exceptional strength and durability, Steel Wire Fabric plays a crucial role in strengthening infrastructure projects. From bridges and tunnels to highways and airports, the integration of Steel Wire Fabric ensures the longevity and resilience of these critical structures. It withstands heavy traffic loads and seismic activities, making it an ideal choice for infrastructure development.7. Quality Assurance:{Remove Brand Name} implements strict quality control measures throughout the manufacturing process of Steel Wire Fabric. It adheres to international standards and undergoes rigorous testing to guarantee its reliability, strength, and conformance to industry regulations. This commitment to quality ensures that builders can rely on Steel Wire Fabric for their construction projects with confidence.[Conclusion]As the construction industry continues to strive for innovation and sustainability, Steel Wire Fabric serves as an invaluable resource. With its exceptional strength, durability, versatility, and cost-effectiveness, it has quickly become a preferred choice for builders and contractors worldwide. With {Remove Brand Name}'s expertise in manufacturing high-quality Steel Wire Fabric, the future of construction is well-poised for increased efficiency, safety, and resilience.

Welded Wire Mesh Manufacturer Innovates with Stainless Steel Materials

In the current market scenario, there is a growing demand for high-quality industrial tools and equipment across different industries. One such industry that is witnessing a high demand for durable, efficient and long-lasting equipment is the construction and manufacturing industry. With this in mind, the Stainless Steel Welded Wire Mesh Factory, situated in China, is providing premium quality welded wire mesh to its clients.The Stainless Steel Welded Wire Mesh Factory is a prominent entity in the welded mesh industry. With over ten years of experience, the factory has achieved a high level of expertise in the manufacturing of welded wire meshes. The company takes pride in its knowledgeable and skilled workforce, which is capable of producing high-quality products designed to meet the specific requirements of customers. The factory operates out of a massive 6,000 square meters facility, allowing for the production of large quantities of welded wire mesh for various applications.Stainless Steel Welded Wire Mesh is made by welding wires together in different patterns to form a square or rectangular mesh structure. The wire mesh is called "Stainless Steel" because it is made from high-quality stainless steel, which ensures the final product to be corrosion-resistant and highly durable. The process of welding the wires together strengthens the wire mesh and makes it more efficient and long-lasting. The mesh is becoming increasingly popular in the construction and manufacturing industries due to its versatility and strength.The Stainless Steel Welded Wire Mesh Factory understands the value of quality and durability, which is why they use the best quality raw materials available in the market. The company's machines are of the highest quality, which helps in producing precision-welded wire meshes that meet the exact specifications of the customers. The factory's team of engineers and technicians regularly upgrade their sector-specific knowledge and skills, enabling them to provide consistent, high-quality products to their clients.Some of the top applications of stainless-steel welded wire mesh include fencing, partitions, storage cages, decks, and gabion mesh. In addition to these applications, the wire mesh has found its way into several industrial processes, including filtration, sieving, and sparging processes. With its versatility and sturdiness, the Stainless Steel Welded Wire Mesh factory can provide custom-built meshes for clients' specific applications.The company has built its reputation on quality and timely delivery, and this is evident in its commitment to customer satisfaction. The company offers affordable prices to its customers while ensuring that the products are delivered within the stipulated time frame.At the Stainless Steel Welded Wire Mesh Factory, quality control is a top priority. Every stage of the manufacturing process is closely monitored, from the selection of raw materials to the final packaging of the finished product. The company uses advanced testing equipment to ensure that the wire mesh produced meets the desired quality criteria, including tensile strength, corrosion resistance, and structural stability.In conclusion, the Stainless Steel Welded Wire Mesh Factory is a leader in the production of welded wire mesh, providing quality and durable products to clients across different industries. The company's commitment to quality, precision, and timely delivery has helped it build a loyal customer base. With its highly knowledgeable and skilled workforce, state-of-the-art equipment, and stringent quality control processes, the factory is positioned to meet the demands of the ever-growing market for welded wire mesh.

Innovative Wire Cloth Weaving Technique Promises High-quality Results

Woven Wire Cloth Revolutionizing Industrial ApplicationsWire cloth is an essential component in a wide range of industrial applications, providing filtration, separation, and protection solutions across various industries. However, one particular innovation is making waves in the field of wire cloth manufacturing – Square Weave Wire Cloth. This cutting-edge technology is revolutionizing the industry with its remarkable performance, durability, and versatility.Square Weave Wire Cloth, developed by a leading manufacturer in the wire cloth industry, offers an unparalleled solution for industrial filtration needs. With its intricate weaving pattern and high-quality materials, this wire cloth ensures efficient and precise filtration, surpassing traditional alternatives in terms of performance and durability.The square weave pattern is vital to the cloth's exceptional properties. Comprising uniformly spaced wires that intersect at right angles, this pattern creates a sturdy and dense structure that provides superior strength and rigidity. This inherent strength enables the wire cloth to withstand heavy loads, high pressures, and abrasive materials without compromising its filtering capabilities.The manufacturing process of Square Weave Wire Cloth involves state-of-the-art machinery and techniques, guaranteeing precision and consistency in every wire cloth produced. The wires used in this cloth are carefully selected based on their material properties, ensuring resistance to corrosion, heat, and wear. This makes Square Weave Wire Cloth suitable for even the harshest and most demanding industrial environments.Square Weave Wire Cloth finds application in diverse industries, including oil and gas, chemical processing, food and beverage, pharmaceuticals, mining, and more. In the oil and gas sector, it is commonly used for sand control in oil wells, preventing the entry of sand particles while allowing fluid flow. In chemical processing plants, this wire cloth acts as a reliable filter medium, separating solids from liquids or gases. The food and beverage industry utilizes Square Weave Wire Cloth for its efficient particle retention capabilities, ensuring the purity of products. Moreover, this wire cloth finds extensive usage in mining operations, providing effective filtration solutions in ore processing and tailings management.The versatility of Square Weave Wire Cloth is a significant factor contributing to its success. Available in various material options such as stainless steel, brass, bronze, and nickel alloys, this wire cloth can be tailored to meet specific industrial requirements. Additionally, it can be manufactured in a wide range of mesh sizes, allowing for precise filtration based on particle size. Whether it is microfiltration, particle separation, or simple protection, Square Weave Wire Cloth can be customized to achieve the desired outcomes.Reliability and longevity are crucial aspects in industrial applications, and Square Weave Wire Cloth excels in both. Its robust construction and durable materials ensure a longer service life, reducing maintenance costs and downtimes. Furthermore, the high-quality manufacturing process guarantees consistent performance, making it a reliable filtration solution for critical applications.In conclusion, Square Weave Wire Cloth is an innovative solution revolutionizing the wire cloth industry. With its superior performance, durability, and versatility, this technology has emerged as a game-changer in various industrial sectors. As the demand for efficient filtration solutions continues to grow, Square Weave Wire Cloth proves to be the go-to choice for businesses worldwide. Embracing this advanced wire cloth technology can lead to improved process efficiency, reduced operational costs, and enhanced product quality across industries.

Understanding Wire Cloth in Automotive Applications: Definition and Importance Discussed

Wire Cloth in Automotive Applications: Understanding the Role of Molybdenum (Mo) Wire ClothWire cloth is a popular material used in different industrial applications. It consists of a matrix of interlaced and interconnected wires, designed to provide strength, durability, and filtration properties. In the automotive industry, wire cloth is used in various components, such as air filters, oil filters, fuel filters, and exhaust systems.One of the key benefits of wire cloth in automotive applications is its ability to filter different types of impurities and contaminants that may negatively affect the performance and efficiency of the engine. For example, air filters made of wire cloth can prevent dust, dirt, and other airborne particles from entering the engine's combustion chamber, which can lead to reduced power, fuel economy, and increased emissions.Similarly, oil filters that incorporate wire cloth can trap metal shavings, dirt, and other impurities that may accumulate in the engine oil, ensuring optimal lubrication and preventing premature wear and tear. Fuel filters with wire cloth can also prevent dirt, rust, and other contaminants from entering the fuel system, which can cause engine stalling, decreased performance, and potential safety hazards.Another use of wire cloth in automotive applications is in the exhaust system. Wire cloth can be used as a catalytic converter substrate, providing a large surface area for the chemical reactions that convert harmful pollutants into less harmful compounds. In this case, the selection of the right type of wire cloth is critical to ensure optimal gas flow and conversion efficiency.When it comes to wire cloth for automotive applications, one of the most important factors to consider is the material composition. In particular, the inclusion of molybdenum (Mo) in the wire cloth can provide significant advantages in terms of strength, durability, and corrosion resistance.Molybdenum is a refractory metal that has excellent resistance to high temperatures, corrosion, and wear. When added to wire cloth, it enhances the material's properties, making it suitable for challenging conditions and applications. For example, molybdenum wire cloth is ideal for use in high-temperature environments, such as exhaust systems, where it can withstand the harsh conditions and maintain its structural integrity.Molybdenum wire cloth is also highly resistant to corrosion, making it suitable for use in corrosive environments, such as marine applications. Additionally, it has excellent wear resistance, which can extend the lifespan of the wire cloth and reduce maintenance costs.In conclusion, wire cloth is a versatile material that plays a crucial role in various automotive applications. Its unique properties, such as filtration, strength, and durability, make it suitable for different components, such as air filters, oil filters, fuel filters, and exhaust systems. When it comes to selecting wire cloth for automotive applications, the inclusion of molybdenum (Mo) can provide significant benefits in terms of high-temperature resistance, corrosion resistance, and wear resistance. By choosing the right wire cloth for your automotive application, you can ensure optimal performance, efficiency, and durability.