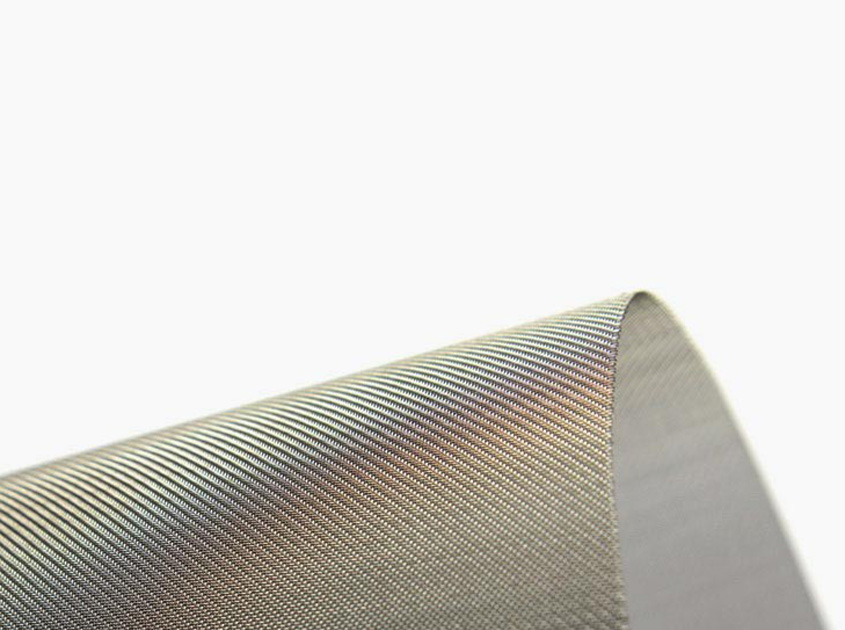

High-Quality Copper Wire Mesh Cloth for Various Applications

By:Admin

{Company} is a leading manufacturer and supplier of copper wire mesh cloth, providing high-quality products to customers worldwide. With years of experience and expertise in the industry, {Company} has established itself as a trusted and reliable source for copper wire mesh cloth, offering a wide range of specifications and customization options to meet the unique needs of different industries.

The unique properties of copper wire mesh cloth make it an ideal material for many applications. Its high conductivity, corrosion resistance, and durability make it suitable for use in electrical and electronic applications. It is commonly used in RF shielding, grounding, and as a conductive material in various electronic devices. In addition, its antimicrobial properties make it an excellent choice for use in air filtration and medical equipment, where a clean and sterile environment is essential.

Furthermore, copper wire mesh cloth is also widely used in architectural and decorative applications. Its malleability and aesthetic appeal make it an attractive choice for interior and exterior design elements. It can be used in decorative panels, wall cladding, and furniture to add a touch of elegance and sophistication to any space.

{Company} offers a wide range of copper wire mesh cloth products to meet the diverse needs of its customers. From fine and ultra-fine mesh for filtration and separation applications to coarser mesh for architectural and decorative purposes, {Company} provides a comprehensive range of options to suit various needs. In addition, {Company} also offers customization services to provide customers with tailored solutions to meet their specific requirements.

With a commitment to quality and customer satisfaction, {Company} ensures that its copper wire mesh cloth products meet the highest standards of performance and reliability. Utilizing advanced manufacturing processes and stringent quality control measures, {Company} delivers products that consistently meet and exceed customer expectations.

As a global leader in the industry, {Company} not only provides high-quality products but also offers exceptional customer service and technical support. Its team of experienced professionals is dedicated to helping customers find the right solutions for their specific needs, offering expert advice and guidance throughout the process. Whether it's product selection, customization, or technical specifications, {Company} is committed to providing comprehensive support to ensure customer success.

In addition to its dedication to quality and customer satisfaction, {Company} also prioritizes environmental sustainability in its manufacturing processes. By adopting eco-friendly practices and utilizing renewable resources, {Company} strives to minimize its environmental footprint and contribute to a greener and more sustainable future.

With its extensive range of high-quality products, commitment to customer satisfaction, and dedication to environmental sustainability, {Company} has established itself as a trusted and reliable partner for copper wire mesh cloth solutions. As the demand for this versatile and essential material continues to grow across different industries, {Company} is well-positioned to meet the needs of its customers and drive innovation in the field.

In conclusion, copper wire mesh cloth is a valuable material with a wide range of applications, and {Company} is a leading manufacturer and supplier that provides high-quality products and exceptional customer support. With its commitment to quality, customization options, and sustainability, {Company} is dedicated to meeting the diverse needs of its customers and driving continued growth and innovation in the industry.

Company News & Blog

Hydraulic Oil Filter Element for Effective Filtration

Title: Langfang Weierda Filtration Equipment Co. LTD Introduces Advanced Hydraulic Oil Filter Element 8231046410Introduction:Langfang Weierda Filtration Equipment Co. LTD, a leading filtration solutions provider based in China, takes pride in announcing the launch of their advanced hydraulic oil filter element 8231046410. This cutting-edge product aims to enhance filtration efficiency and overall system performance by effectively removing impurities and maintaining oil cleanliness. With a commitment to delivering superior quality filtration systems, Weierda Filtration Equipment continues to be a trusted manufacturer and supplier in the industry.Hydraulic Oil Filter Element 8231046410: Highlighting Superior Filtration CapabilitiesThe hydraulic oil filter element 8231046410, developed by Langfang Weierda Filtration Equipment Co. LTD, is a breakthrough product that meets the evolving needs of customers in the hydraulic oil filtration industry. With its exceptional design and high-quality materials, this filtration element offers unparalleled performance and reliability.The importance of efficient oil filtration cannot be overstated. Impurities such as dirt, debris, and particulate matter can significantly impact the performance and longevity of hydraulic systems. The hydraulic oil filter element 8231046410 effectively removes these contaminants, ensuring optimal oil cleanliness within the system. This, in turn, prevents the wear and tear of expensive hydraulic components, reducing maintenance costs and enhancing the lifespan of the equipment.Advanced Features and Benefits:1. Superior Filtration Efficiency: The hydraulic oil filter element 8231046410 integrates advanced filtration technologies, enabling it to efficiently capture and remove even the smallest particles. With an impressive filtration efficiency, it delivers impeccable performance, ensuring the hydraulic system operates at its full potential.2. Enhanced Durability: Weierda Filtration Equipment Co. LTD utilizes high-quality materials in the manufacturing process of the hydraulic oil filter element, resulting in a durable product that can withstand harsh operating conditions. It ensures longevity even in demanding applications, providing customers with a cost-effective filtration solution.3. Easy Maintenance: The design of the hydraulic oil filter element 8231046410 facilitates convenient maintenance processes. With its user-friendly features, replacing the filter element is a hassle-free task, ensuring minimal downtime and uninterrupted system operation.4. Customization Options: Langfang Weierda Filtration Equipment Co. LTD understands the diverse requirements of their customers. As a result, they offer customizable options for the hydraulic oil filter element 8231046410, catering to specific filtration needs. This flexibility allows customers to tailor the product to suit various applications, ensuring optimum filtration performance.Company Introduction: Weierda Filtration Equipment Co. LTDWeierda Filtration Equipment Co. LTD is a renowned manufacturer of filtration systems, specializing in hydraulic oil filtration. With years of industry experience and a team of skilled professionals, the company has gained a reputation for delivering innovative solutions and exceptional customer service. Committed to quality, Weierda Filtration Equipment prioritizes continuous research and development to meet the evolving demands of the filtration industry.Conclusion:Langfang Weierda Filtration Equipment Co. LTD's launch of the hydraulic oil filter element 8231046410 represents a significant advancement in hydraulic oil filtration technology. With its superior filtration efficiency, durability, easy maintenance, and customization options, this product reaffirms Weierda Filtration Equipment's commitment to providing cutting-edge solutions to customers worldwide. By opting for the hydraulic oil filter element 8231046410, customers can enjoy improved system performance, extended equipment lifespan, reduced maintenance costs, and peace of mind knowing their hydraulic systems are in reliable hands.

Crimped Wire Mesh: An Essential Guide to Understanding its Applications and Benefits

Title: Innovative Crimped Wire Mesh Revolutionizing Various IndustriesIntroduction:Wire mesh has long been recognized as one of the most versatile and widely used materials, finding applications in numerous industries. One particular innovation that is quickly gaining prominence is Crimped Wire Mesh, an advanced technology that offers enhanced durability, strength, and flexibility. This revolutionary product has opened up new possibilities in industries such as construction, mining, agriculture, and filtration, making it an increasingly popular choice across various sectors.1. Crimped Wire Mesh in the Construction Industry:With its unique crimping pattern and interlocking design, Crimped Wire Mesh has become an indispensable component in the construction industry. It is extensively used in reinforcement applications, concrete slabs, precast panels, and retaining walls. The robust and flexible nature of the mesh ensures structural integrity, while allowing for adequate ventilation and even distribution of stress. Additionally, its corrosion-resistant properties make it suitable for both interior and exterior applications, ensuring longevity and durability.2. Industrial Applications of Crimped Wire Mesh:The mining and quarrying industry greatly benefits from the use of Crimped Wire Mesh. It is utilized in screens for vibrating equipment, providing efficient separation and classification of various materials. The mesh's high tensile strength and resistance to abrasion make it ideal for demanding environments, where it can endure extreme temperatures and harsh operating conditions. Crimped Wire Mesh also finds application in heavy-duty shaker screens, sand control screens, and quarry meshing processes, ensuring efficient productivity and minimizing downtime.3. Agricultural Implementations of Crimped Wire Mesh:In the agricultural sector, Crimped Wire Mesh plays a vital role in maintaining productivity and protecting crops. It is widely used in livestock fencing, poultry cages, trellises, and fruit tree support systems. The mesh's corrosion resistance and robust construction allow for reliable and long-lasting use, with minimal maintenance requirements. Additionally, Crimped Wire Mesh provides excellent protection against pests and predators, ensuring the safety and well-being of animals and crops alike.4. Filtration and Sieving Applications:Crimped Wire Mesh is an essential component in various filtration and sieving processes across different industries. Its precise woven pattern allows for efficient particle separation and filtering, making it an ideal choice for water treatment facilities, pharmaceutical manufacturing, and food processing industries. The mesh can be customized to meet specific requirements, ensuring precise filtration, particle retention, and improved overall production quality.Conclusion:The innovation of Crimped Wire Mesh has revolutionized multiple industries by offering superior durability, strength, and flexibility. Its diverse applications in construction, mining, agriculture, and filtration have reshaped industry standards, allowing for improved efficiency and productivity. As the demand for this versatile material continues to grow, it is expected to find even more applications in emerging fields. With its many benefits, Crimped Wire Mesh is set to become a cornerstone in various industries, contributing to enhanced performance and long-term sustainability.

Welded Wire Mesh Manufacturer Innovates with Stainless Steel Materials

In the current market scenario, there is a growing demand for high-quality industrial tools and equipment across different industries. One such industry that is witnessing a high demand for durable, efficient and long-lasting equipment is the construction and manufacturing industry. With this in mind, the Stainless Steel Welded Wire Mesh Factory, situated in China, is providing premium quality welded wire mesh to its clients.The Stainless Steel Welded Wire Mesh Factory is a prominent entity in the welded mesh industry. With over ten years of experience, the factory has achieved a high level of expertise in the manufacturing of welded wire meshes. The company takes pride in its knowledgeable and skilled workforce, which is capable of producing high-quality products designed to meet the specific requirements of customers. The factory operates out of a massive 6,000 square meters facility, allowing for the production of large quantities of welded wire mesh for various applications.Stainless Steel Welded Wire Mesh is made by welding wires together in different patterns to form a square or rectangular mesh structure. The wire mesh is called "Stainless Steel" because it is made from high-quality stainless steel, which ensures the final product to be corrosion-resistant and highly durable. The process of welding the wires together strengthens the wire mesh and makes it more efficient and long-lasting. The mesh is becoming increasingly popular in the construction and manufacturing industries due to its versatility and strength.The Stainless Steel Welded Wire Mesh Factory understands the value of quality and durability, which is why they use the best quality raw materials available in the market. The company's machines are of the highest quality, which helps in producing precision-welded wire meshes that meet the exact specifications of the customers. The factory's team of engineers and technicians regularly upgrade their sector-specific knowledge and skills, enabling them to provide consistent, high-quality products to their clients.Some of the top applications of stainless-steel welded wire mesh include fencing, partitions, storage cages, decks, and gabion mesh. In addition to these applications, the wire mesh has found its way into several industrial processes, including filtration, sieving, and sparging processes. With its versatility and sturdiness, the Stainless Steel Welded Wire Mesh factory can provide custom-built meshes for clients' specific applications.The company has built its reputation on quality and timely delivery, and this is evident in its commitment to customer satisfaction. The company offers affordable prices to its customers while ensuring that the products are delivered within the stipulated time frame.At the Stainless Steel Welded Wire Mesh Factory, quality control is a top priority. Every stage of the manufacturing process is closely monitored, from the selection of raw materials to the final packaging of the finished product. The company uses advanced testing equipment to ensure that the wire mesh produced meets the desired quality criteria, including tensile strength, corrosion resistance, and structural stability.In conclusion, the Stainless Steel Welded Wire Mesh Factory is a leader in the production of welded wire mesh, providing quality and durable products to clients across different industries. The company's commitment to quality, precision, and timely delivery has helped it build a loyal customer base. With its highly knowledgeable and skilled workforce, state-of-the-art equipment, and stringent quality control processes, the factory is positioned to meet the demands of the ever-growing market for welded wire mesh.

Top Manufacturers in the Industry Offering High-Quality Crimped Wire Mesh

Title: Crimped Wire Mesh Manufacturers Innovate with New Solutions to Cater to Diverse Industry NeedsIntroduction:In today's rapidly evolving industrial landscape, businesses are continuously seeking reliable and innovative solutions to meet their specific requirements. One such sector that has witnessed substantial growth is the wire mesh industry. Renowned Crimped Wire Mesh Manufacturers, known for their excellence in providing premium wire products, have recently introduced a range of groundbreaking solutions tailored to meet the diverse demands of various industries.Crimped Wire Mesh: A Versatile SolutionCrimped wire mesh is widely recognized for its versatility and strength. It is a popular choice in industries such as mining, construction, agriculture, automotive, and more. Manufacturers have long utilized the crimping technique to increase the mesh's rigidity and resistance, making it suitable for high-stress applications, ranging from filtration and separation to reinforcement and protection.Understanding the constant need for innovative products, Crimped Wire Mesh Manufacturers have gone a step further by expanding their product range and incorporating cutting-edge technologies, ensuring enhanced performance and durability.Advanced Engineering Techniques Redefine Wire Mesh StandardsTo stay ahead in the ever-competitive market, manufacturers have invested in advanced engineering techniques that redefine industry standards. By utilizing state-of-the-art machinery and technology, they can produce wire mesh products that offer superior quality, precision, and customization.One such technique gaining prominence is computer numerical control (CNC) wire mesh manufacturing. Through CNC technology, manufacturers can create intricate and complex wire mesh designs, enabling precise customization according to client specifications. This flexibility allows businesses to optimize their operations for maximum efficiency and productivity.Innovations in Materials: Expanding the PossibilitiesCrimped Wire Mesh Manufacturers have also turned their attention to exploring alternative materials for mesh production. By harnessing the potential of new alloys and composites, they aim to enhance the material properties needed for specific applications.For example, manufacturers have developed stainless steel wire mesh variants that exhibit increased resistance to corrosion. This innovation makes them ideal for demanding environments, such as marine applications, chemical processing plants, and oil refineries.Similarly, the development of high-tensile wire mesh has revolutionized industries that require robust solutions. Providing superior strength-to-weight ratios, these meshes are used in construction, agriculture, and transportation sectors, enabling businesses to optimize resources without compromising on safety or performance.Addressing Environmental Concerns: Sustainable SolutionsIn addition to product advancements, Crimped Wire Mesh Manufacturers are actively addressing environmental concerns. For instance, they have introduced eco-friendly coatings that reduce carbon emissions and minimize ecological footprints. By adopting greener manufacturing practices, these manufacturers ensure that their products contribute to sustainable development efforts.Furthermore, manufacturers are actively promoting recycling programs to responsibly manage their products' end-of-life cycle. By encouraging customers to return used wire mesh for recycling, they contribute to the circular economy, reducing waste and conserving natural resources.Expanding Global Footprint: Strengthening PartnershipsCrimped Wire Mesh Manufacturers are also focusing on expanding their global footprint by forging strategic partnerships. Collaborative efforts with distributors, suppliers, and end-users across various industries enable them to understand market dynamics better and cater to specific regional requirements.Through these partnerships, they can gather valuable feedback, enabling continuous product improvements and staying at the forefront of industry trends. Moreover, these alliances foster knowledge exchange, paving the way for future innovations and sustainable growth.Conclusion:Crimped Wire Mesh Manufacturers continue to redefine industry standards through their commitment to innovation, advanced engineering techniques, and sustainable practices. By adapting to the evolving needs of diverse industries, they provide solutions that excel in strength, versatility, and customization. As the demands of the market grow, the industry can expect further advancements and collaborations that will shape the future of wire mesh applications.

Global Analysis of Woven Cloth For Copper Market 2020: Market Size by Types, Applications, Regions, and Manufacturers Revealed - a2z Press Release

Woven Copper Cloth: A Versatile Material for Various ApplicationsCopper has been used for centuries due to its excellent electrical conductivity, heat resistance, and corrosion resistance. It finds applications in various industries, ranging from electronics and electricals to automotive, aerospace, and construction. To enhance the properties of copper and make it suitable for diverse applications, woven copper cloth has emerged as a versatile material. In this blog post, we will explore the global market for woven copper cloth, its types, applications, and key manufacturers.Woven copper cloth, as the name suggests, is a fabric created by interweaving copper wires. This process produces a durable and flexible cloth that exhibits exceptional electrical conductivity, electromagnetic shielding, and thermal conductivity properties. The interlocking structure of the woven cloth ensures its strength and integrity, making it suitable for a range of industrial applications.One of the key applications of woven copper cloth is in the electronics and electricals industry. It is widely used as a grounding material in electronic circuitry, providing a low-resistance pathway for the flow of electric current. Its ability to effectively shield electromagnetic radiation makes it an ideal material for creating Faraday cages and shielding enclosures that protect sensitive electrical equipment from interference.The automotive industry also benefits from the use of woven copper cloth. It is employed in various car components, including gaskets, seals, and automotive wiring harnesses, where its high electrical conductivity helps in maintaining efficient electrical connections and preventing signal loss. Moreover, its corrosion-resistant properties make woven copper cloth an excellent choice for automotive applications, ensuring longevity and reliability.In the aerospace sector, woven copper cloth finds applications in the construction of aircraft parts and components. Its lightweight yet robust nature makes it an ideal material for manufacturing lightweight yet durable aircraft structures. Additionally, woven copper cloth's thermal conductivity properties enable effective heat dissipation in aerospace equipment, preventing overheating and enhancing overall performance.The construction industry also recognizes the benefits of woven copper cloth. It is utilized in various architectural applications, such as roofing, façades, and decorative elements. Woven copper cloth's natural patina gives it an aesthetically pleasing appearance, making it a popular choice for architectural designs. Furthermore, its antimicrobial properties make it a suitable material for healthcare facilities and other environments where cleanliness and hygiene are vital.The global market for woven copper cloth is witnessing significant growth due to the increasing demand for copper-based products across industries. Several key manufacturers contribute to this market, including (remove brand names). These companies focus on producing high-quality woven copper cloth to meet the diverse needs of their customers.In conclusion, woven copper cloth has emerged as a versatile material with numerous applications in various industries. With its exceptional electrical conductivity, electromagnetic shielding, and thermal conductivity properties, it provides an excellent solution for enhancing the performance and durability of various products. The global market for woven copper cloth is expanding rapidly, driven by increasing demand and technological advancements. As industries continue to innovate, woven copper cloth will play a crucial role in shaping a sustainable and advanced future.

New Content Filter Provides Enhanced Online Experience for Users

In the era of fast-paced technological advancements, Filter Elements have emerged as one of the most sought-after industries, catering to the needs of multiple sectors, including Automotive, Pharmaceutical, Food & Beverage, and many more. One such company which has been revolutionizing the filtration industry is the Germany-based Filter Elements.Filter Elements, established in 1992, is a leading manufacturer of high-quality filters, providing innovative solutions in air, liquid, and gas filtration. With its focus on customer satisfaction, technology-driven approach, and high-quality products, Filter Elements has been successful in carving a niche for itself in the global filtration market.The company caters to various sectors such as Automotive, Industrial, Marine, Petrochemical, Power Generation, and many more. It offers a wide range of products, including Hydraulic Filters, Air Filters, Oil Filters, Fuel Filters, and other functional filters, which meet the industry's requirements and ensure maximum efficiency. With its advanced research and development facilities, Filter Elements has been able to come up with innovative and customized filtering solutions that cater to the specific needs of its clients.Quality is of utmost importance to Filter Elements, and it ensures that all its products undergo strict quality checks and adhere to international standards. The company has a state-of-the-art manufacturing facility, which employs advanced technologies and techniques to produce high-quality filters. With its team of skilled professionals, Filter Elements has been able to maintain its position as a leading brand in the filtration industry.In addition to its focus on quality, the company also places great emphasis on sustainability. Filter Elements recognizes the importance of environment-friendly practices, and hence, it has adopted green manufacturing processes. It ensures that its products are free from harmful chemicals and materials, thereby contributing to a cleaner and safer environment.Filter Elements has a global presence, with its products being distributed in over 80 countries worldwide. The company has collaborations and partnerships with leading organizations in the filtration industry, which have helped it to stay ahead of the competition. With its dedication to innovation, quality, and sustainability, Filter Elements is poised for growth and success in the filtration industry.Filter Elements has recently launched a new range of filters that caters to the automotive industry. The Automotive Filters range includes air filters, oil filters, fuel filters, and cabin air filters, which are designed to provide maximum protection to the vehicle's engine, ensuring its longevity and efficiency. The new range of filters has been designed using advanced technologies and materials, which enhance its overall performance.The Automotive Filters range has been specifically designed to meet the requirements of vehicles in various regions. The filters cater to the needs of vehicles in extreme conditions, such as high temperatures, dusty environments, and polluted areas. The filters ensure that the vehicle's engine performs optimally, providing an excellent driving experience.The new range of filters has been well-received by the automotive industry, with many vehicle manufacturers opting for Filter Elements' Automotive Filters to ensure the highest level of protection for their vehicles' engines.Filter Elements' commitment to customer satisfaction and quality products has been recognized by various industry experts, who have awarded the company with numerous accolades. In 2020, Filter Elements was awarded the GHP Environmental Award for its eco-friendly practices. The company has also been recognized for its outstanding contributions to the filtration industry by various industry associations, including the Association of the Nonwoven Fabrics Industry (INDA).In conclusion, Filter Elements is a leading brand in the filtration industry, providing innovative and customized solutions to various sectors. With its focus on quality, sustainability, and customer satisfaction, the company has been able to carve a niche for itself in the global market. The launch of the new Automotive Filters range is a testament to the company's commitment to innovation and excellence. As the world continues to progress towards sustainable practices, Filter Elements is well-positioned to be at the forefront of the filtration industry.

How to Clean Stainless Steel Mesh with a Reliable Cleaning Cloth

Stainless Steel Mesh Cleaning Cloth - The Ultimate Solution for All Your Cleaning NeedsCleaning is an essential part of our daily routine, be it at home, office, or any other commercial space. It not only helps us maintain hygiene but also prevents the spread of diseases and infections. With the increasing awareness of the importance of hygiene, the demand for cleaning tools has also increased. One such essential tool is a stainless steel mesh cleaning cloth that has become the ultimate solution for all your cleaning needs.Stainless Steel Mesh Cleaning Cloth – The Perfect Cleaning SolutionStainless steel mesh cleaning cloths are made from high-quality stainless steel mesh and are designed to clean thoroughly without scratching or damaging surfaces. Whether it's cleaning dishes, kitchen appliances, bathroom fixtures, or any other surface, these cloths do an excellent job of removing dirt, grime, and stains, leaving the surface sparkling clean.The unique design of the stainless steel mesh cleaning cloth makes it stand out from other cleaning cloths in the market. The tightly-woven mesh construction ensures that the cloth does not scratch or damage delicate surfaces, making it perfect for cleaning expensive appliances, cookware, glass, and mirrors. It is also strong enough to remove stubborn stains and dirt with ease, making it the perfect cleaning tool for any surface.Easy to Use and MaintainOne of the primary reasons stainless steel mesh cleaning cloths are so popular is that they are incredibly easy to use and maintain. They don't require any special equipment or cleaning supplies, and they can be washed and reused multiple times. Simply wet the cloth with water, wring out the excess water, and start cleaning. Rinse the cloth with clean water after use, and it's ready to be used again.Another significant advantage of stainless steel mesh cleaning cloths is that they are machine washable. However, it is important to note that they should be washed separately from other fabrics to avoid damage to delicate surfaces.Bringing You the Best Quality Stainless Steel Mesh Cleaning ClothsThere are many brands of stainless steel mesh cleaning cloths available in the market. However, choosing the right brand can be challenging. At our company, we strive to bring you the best quality stainless steel mesh cleaning cloths that not only meet but exceed your expectations.Our stainless steel mesh cleaning cloths are made from high-quality stainless steel mesh and are designed to last longer than other brands in the market. The tightly-woven mesh construction ensures the cloths do not leave behind any scratches or marks on delicate surfaces, making them ideal for cleaning expensive appliances and other surfaces.We understand that every customer has unique cleaning needs, and that is why we offer a range of stainless steel mesh cleaning cloths to suit different purposes. Whether you need a cloth to clean your kitchen, bathroom, or any other surface, we have a solution for you. Our cloths are available in different sizes and designs to make cleaning more comfortable and efficient for you.Our commitment to quality and customer satisfaction is reflected in the positive feedback we've received from our customers. We believe in providing the best value for your money, and that is why we offer our stainless steel mesh cleaning cloths at competitive prices.Conclusion:Stainless steel mesh cleaning cloths have become an essential tool for maintaining hygiene and cleanliness in our daily lives. They are strong, durable, and gentle on delicate surfaces, making them ideal for cleaning all kinds of surfaces. Our company brings you the best quality stainless steel mesh cleaning cloths that are designed to last longer than other brands in the market. We offer a range of cloths to suit different cleaning needs and are committed to providing the best value for your money. Try our cleaning cloths today, and experience the difference for yourself!

Metal Woven Copper Wire Mesh for Industrial Use, Packed in Rolls at Rs 150/Meter

Title: The Versatility of Copper Wire Mesh Roll: Ideal for Industrial ApplicationsIntroduction:Copper wire mesh has gained significant popularity in various industries due to its exceptional properties and versatility. This blog will delve into the applications and benefits of metal woven copper wire mesh, particularly in its roll packaging form. With a focus on industrial usage, we will explore the features, advantages, and key considerations of this product. Additionally, we will highlight the benefits of incorporating copper wire mesh roll and its impact on various industries.1. Understanding Copper Wire Mesh Roll:Copper wire mesh, available in a roll packaging type, presents an easily adaptable and flexible solution for numerous industrial applications. This woven mesh is crafted using highly durable copper wires, ensuring excellent tensile strength, conductivity, and longevity.2. Importance of Copper Wire Mesh in Industrial Applications:The industrial sector greatly benefits from the utilization of copper wire mesh roll due to its diverse range of properties and applications. Some key areas where copper mesh finds value are:a. Filtration and Separation:Copper wire mesh offers outstanding filtration capabilities, making it ideal for separating solids from liquids or gases. The fine mesh size options ensure effective separation of particles, making it valuable in industries such as petrochemicals, pharmaceuticals, and food processing.b. Electrical Applications:Copper wire mesh is highly conductive, making it an excellent choice for various electrical applications. Its electrical conductivity properties allow for efficient current flow, making copper mesh roll suitable for transformers, power generation, electronics, and more.c. Anti-Insect Screens:Copper wire mesh roll finds application as an effective anti-insect screen due to its durability and corrosion resistance. It acts as a protective barrier in windows, doors, or vents, preventing the entry of insects while still maintaining airflow.d. EMI and RFI Shielding:Copper wire mesh roll is also widely utilized for EMI (Electromagnetic Interference) and RFI (Radio Frequency Interference) shielding in industries dealing with sensitive electronic equipment. Its high conductivity and mesh design effectively divert electromagnetic waves, ensuring the safety and proper functioning of electronic devices.3. Advantages of Copper Wire Mesh Roll:Incorporating copper wire mesh roll in industrial processes offers several advantages that set it apart from other alternatives:a. High Strength and Durability:Copper wire mesh roll displays remarkable tensile strength, enabling it to withstand high temperatures, pressure, and abrasive environments. Its excellent corrosion resistance further enhances its durability, making it a long-lasting solution.b. Excellent Conductivity:The exceptional electrical conductivity of copper wire mesh ensures efficient current flow, reducing energy loss and improving performance in electrical applications. This property enables it to act as a reliable conductor, particularly essential in electrical and electronics industries.c. Easy Adaptability:Copper wire mesh roll can be easily tailored to meet specific application requirements. Its flexibility and versatility allow it to fit seamlessly into various industrial processes, including custom filtration systems and shielding applications.d. Environmental Sustainability:Copper is a recyclable material, making copper wire mesh roll an environmentally friendly choice. Its sustainability factor adds value to industries seeking greener alternatives while still maintaining the desired functionality.Conclusion:The metal woven copper wire mesh roll emerges as a versatile solution for a range of industrial applications. Its superior strength, flexibility, electrical conductivity, and recyclability make it an ideal choice for sectors such as filtration, electrical, insect screening, and EMI/RFI shielding. With its numerous advantages, copper wire mesh roll continues to play a pivotal role in enhancing efficiency, productivity, and performance across various industries.

Discover a Comprehensive Directory of Woven Taffeta and Other Textile Fabrics

The world of textiles is a vast and diverse one, covering a multitude of fabrics used in a variety of industries. Among these fabrics is woven metal fabric, a material that has gained increasing popularity in recent times. In this article, we will take a closer look at woven metal fabric, its properties, applications, and the textile manufacturing industry as a whole.Woven metal fabric is a material made by weaving metal wires together. These wires can be made from a variety of metals such as stainless steel, bronze, and aluminum, among others. The weaving process can be done using traditional methods or advanced machinery, depending on the desired outcome and purpose of the fabric.One of the most notable properties of woven metal fabric is its durability and strength. Due to its metal composition, this fabric can withstand high temperatures, harsh weather conditions, and resist corrosion. Its strength makes it ideal for use in various applications such as architectural, industrial, and even in fashion.In architecture, woven metal fabric is used for its decorative properties as well as its functionality. It can be used to create stunning facades and as cladding for buildings, adding an elegant and modern touch to any structure. It can also be used for sun control, providing shade while allowing natural light to filter through.In industrial settings, woven metal fabric is used for filtration, where it can be used in the creation of filters for gas and liquid processing and separation. It is also used in conveyor systems, as it can withstand heavy loads and resist wear and tear.In fashion, woven metal fabric has been used for a variety of purposes, including clothing, jewelry, and accessories. It can be woven into intricate patterns and shapes and used to create stunning pieces that are both functional and stylish.The textile manufacturing industry is a vast and complex one, covering a multitude of fabrics used in various industries such as fashion, architecture, and industrial applications. In textile manufacturing, fabrics are created using a variety of methods such as weaving, knitting, and finishing.The woven metal fabric is created using a weaving method, where metal wires are interlaced together to form a pattern. The weaving process can be done using traditional methods or advanced machinery, depending on the desired outcome and purpose of the fabric.The textile manufacturing industry also covers a multitude of fabrics, including taffeta and other woven and knit fabrics. These fabrics are used for various applications and purposes, from clothing to home decor to industrial uses.In conclusion, woven metal fabric is a unique and versatile material that has gained increasing popularity in recent times due to its durability, strength, and versatility. Its use in architecture, industrial applications, and even in fashion has made it a sought-after material. As the textile manufacturing industry continues to evolve and expand, the use of fabrics such as taffeta, knit, and woven metal fabric will continue to be essential in various applications and industries.