High-Quality Wire Mesh Insect Screen for Ultimate Protection

By:Admin

In today's world, where comfort and cleanliness are valued more than ever, keeping insects out of our homes and buildings has become a top priority. The prevalence of flying insects and bugs not only poses a threat to hygiene but also disrupts the peaceful ambiance of our living and working spaces. Fortunately, there is a reliable solution to this common problem - wire mesh insect screens.

One of the leading providers of high-quality wire mesh insect screens is {Company Name}. Established in the early 2000s, the company has been dedicated to manufacturing and supplying premium insect screens to meet the demands of both residential and commercial markets. With a commitment to quality and customer satisfaction, {Company Name} has become a trusted name in the industry, known for its durable and effective insect screening solutions.

The wire mesh insect screens offered by {Company Name} are designed to provide protection against a wide range of insects, including mosquitoes, flies, bees, and other unwanted pests. Made from high-grade materials, these screens are not only effective in keeping insects out but also provide ventilation and natural light, without compromising the aesthetics of the surrounding environment.

One of the key features of {Company Name}'s wire mesh insect screens is their durability. Constructed with precision and attention to detail, these screens are built to withstand harsh weather conditions and constant use, making them a long-term investment for any property. The screens are also available in a variety of sizes, colors, and designs, catering to the diverse needs of customers.

In addition to their functionality, the wire mesh insect screens from {Company Name} are easy to install and maintain. Customers can choose from different mounting options, including fixed, hinged, and sliding screens, to suit their specific requirements. Moreover, the screens are designed to be easily cleaned, ensuring that they remain hygienic and free from dust and debris.

{Company Name} takes pride in its commitment to innovation and continuous improvement. In line with this, the company's research and development team is constantly exploring new technologies and materials to enhance the performance and efficiency of its insect screens. This dedication to advancement ensures that customers receive cutting-edge solutions that provide maximum protection and comfort.

As the demand for insect screening solutions continues to grow, {Company Name} remains steadfast in its mission to deliver top-quality products and exceptional customer service. The company's team of experts is readily available to provide advice and assistance to customers, from choosing the right type of wire mesh insect screen to installation and after-sales support.

With a proven track record of reliability and performance, it's no wonder that {Company Name} has become the go-to choice for many when it comes to wire mesh insect screens. Whether it's a residential property, a commercial establishment, or an industrial facility, {Company Name} has the expertise and resources to cater to the needs of all clients, providing them with peace of mind and a bug-free environment.

In conclusion, wire mesh insect screens from {Company Name} offer a reliable and effective solution to keep pesky insects at bay. With their durability, ease of installation, and innovative features, these screens are a must-have for any property looking to maintain hygiene, comfort, and an insect-free environment. As the leading provider of insect screening solutions, {Company Name} continues to set the standard for quality and excellence in the industry.

Company News & Blog

Understanding the Application and Benefits of 5 Micron Filters: An Insightful Article by Brian Farno

Innovative Filtering Solutions Offer Enhanced Performance for Various Industries[City], [Date] - As industries continue to evolve and demand higher efficiency standards, companies are constantly seeking cutting-edge solutions to meet their filtration needs. One such company, specializing in filter elements, has introduced a ground-breaking product designed to address the diverse challenges faced by various industries. This novel solution, with a filtration level as low as 5 microns, ensures optimal performance and surpasses traditional filtering methods in terms of efficiency and reliability.With an extensive research and development process, the filter element industry has made significant strides in revolutionizing filtration technology. By reducing the filtration level to as low as 5 microns, manufacturers have crafted a product that offers unparalleled precision in its performance. The new filter element can effectively remove contaminants and impurities that were previously difficult to eliminate, thereby enhancing the overall quality of the output.One of the industries that stands to benefit greatly from this breakthrough is the automotive sector. Engines, especially those in high-performance vehicles, require meticulous filtration to maintain optimum performance. A 5-micron filter element provides a higher level of protection, preventing fine particles and impediments from clogging engines and reducing their efficiency. This newly introduced technology ensures enhanced engine performance and extends the lifespan of critical components, resulting in greater customer satisfaction and cost savings.The refining and chemical industries also rely heavily on efficient filtration systems to maintain product integrity and prevent equipment damage. Traditional filtration methods often fall short in capturing contaminants smaller than 5 microns, leading to compromised product quality and equipment issues. However, the introduction of an advanced 5-micron filter element mitigates these concerns by reliably removing these minute impurities, safeguarding both the product quality and the long-term health of the equipment.Another sector that greatly benefits from this cutting-edge technology is the pharmaceutical industry, where maintaining purity is of paramount importance. As pharmaceutical manufacturing processes require stringent quality control measures, employing a 5-micron filtration system guarantees the removal of even the smallest particulates, bacteria, and other impurities. This ensures the delivery of safe and effective medications, meeting the stringent regulatory requirements set forth by global health authorities.In addition to the direct advantages provided by this exceptional filtration system, its innovative features also yield long-term benefits. The enhanced efficiency of the 5-micron filter element translates to reduced maintenance costs and downtime for businesses. By effectively filtering out particles and contaminants, companies can prevent costly equipment malfunctions and breakdowns, thereby increasing productivity and profitability.To accommodate diverse industry needs, the 5-micron filter element is available in various configurations, including standard cartridges and high-capacity systems. This adaptability ensures compatibility across a wide range of applications and makes it easier for industries to seamlessly integrate the new technology into their existing operations.As the demand for enhanced performance and reliability continues to grow across industries, the introduction of the 5-micron filter element represents a significant advancement in filtration technology. By effectively removing contaminants down to this microscopic level, businesses can now achieve improved outcomes, greater product integrity, increased durability, and reduced maintenance costs. This innovative filtration solution is set to revolutionize the industry and pave the way for a more efficient and sustainable future.

Exploring the Features and Applications of Woven Wire Mesh: An In-depth Look

article as follows:Brass Woven Wire Mesh A Major Breakthrough In Metal FabricationWire mesh fabrication technology has come a long way in recent years. Today, producers can develop a wide array of wire mesh products that meet different customer needs. Among the wire mesh products that have taken the industry by storm is the brass woven wire mesh.Brass woven wire mesh (we will remove the brand name for this purpose) is made from high-quality brass materials that have undergone a series of manufacturing processes. The result is a unique mesh product that is strong, durable, and highly versatile.The innovative brass woven wire mesh is a major breakthrough in the metal fabrication industry. It is a flexible, lightweight, and highly modifiable product that weaves together different strands of brass wires into various mesh shapes and sizes. The design of the brass woven wire mesh allows for easy customization of mesh specifications based on unique application requirements.The attributes of brass woven wire mesh make it an ideal material for use in various industries. Businesses that require high-quality wire mesh products can use this mesh for filtration purposes, as a decorative element, and for applications requiring a barrier. This versatility has made brass woven wire mesh a popular choice among manufacturers in the automotive industry, construction industry, and even the arts and crafts sector.The brass woven wire mesh is an excellent choice for filtration purposes. Its intricate weaving pattern allows for the passage of fluids without allowing debris or other particles to pass through. This quality makes it an ideal material for use in industries that require filtration of air and liquids, such as the pharmaceutical and food industries.Brass woven wire mesh is also a popular choice in the automotive industry where it is often used for airbags. Its strength and durability make it an ideal choice for this application.In the construction industry, brass woven wire mesh is used to reinforce metal fabrication products, such as steel structures. Its unique attributes make it a reliable option for providing support and enhancing the structural integrity of large structures.Brass woven wire mesh is also a widely used decorative element in both commercial and residential applications. Its versatility allows it to be easily modified, making it possible to create unique and original designs that enhance the aesthetics of the space.Manufacturers of brass woven wire mesh employ state-of-the-art technology, high-quality raw materials, and rigorous quality control measures to ensure that their products meet industry standards. This commitment to quality and innovation has set companies that produce this mesh apart from their competitors.Our temporary pared-down mention of a brand name also underscores the importance of choosing the right supplier in this industry. When selecting a supplier, manufacturers should consider the supplier's experience, cost, and quality of products. The right supplier should be able to work with manufacturers to provide customized mesh solutions that meet their specific application needs.In conclusion, brass woven wire mesh is a groundbreaking mesh product that has revolutionized the metal fabrication industry. Its unique attributes make it an ideal material for use in various industries, including filtration, automotive, construction, decorative, and art applications. Manufacturers need to work with reliable suppliers of brass woven wire mesh to ensure that they get high-quality products that meet their specific industry requirements.

High-Quality Woven Wire Screens: A Complete Guide for Effective Screening

Woven Wire Screen Revolutionizing Screen SolutionsWoven wire screens have played a crucial role in various industries for decades. However, the evolution of these screens has been limited, until now. A pioneering company has recently emerged, introducing innovative technology that promises to revolutionize the screen solution industry.This breakthrough has been achieved by an industry leader, known for their dedication to research and development. Their cutting-edge technology presents a major advancement in woven wire screen solutions, which have traditionally been constructed using a simple combination of wires woven together.This new screen solution incorporates a revolutionary manufacturing process that enhances performance, durability, and versatility. The company's engineers have employed advanced techniques to create a wire screen that surpasses all expectations in terms of efficiency and strength.By utilizing state-of-the-art weaving machines, the company is able to produce screens with precise wire tolerances and unparalleled uniformity. This ensures consistent opening sizes across the screen, resulting in improved material separation, increased throughput, and enhanced overall productivity.Furthermore, the enhanced durability of these woven wire screens provides a longer lifespan compared to conventional screens. The precision weaving process creates a robust structure that can withstand heavy loads, abrasion, and corrosion, making it ideal for even the harshest operating conditions.The versatility of this new wire screen is another game-changer. The company offers a broad range of wire materials, each specifically selected to meet the requirements of different applications. From standard carbon steel wire to high-tensile stainless steel, there is a wire that fits every need. This adaptable solution is applicable across diverse industries, such as mining, aggregate processing, recycling, agriculture, and more.In addition to the innovative manufacturing process and material selection, the company has heavily invested in research and development to continuously improve their woven wire screens. Their team of engineers consistently strives for innovation and works closely with clients to address their specific needs.Customer satisfaction is at the forefront of the company's mission. By providing tailored solutions for unique application requirements, they ensure that their clients achieve optimal outcomes. Whether it is custom screen dimensions, special wire materials, or specific opening sizes, the company is committed to delivering a screen solution that perfectly suits individual demands.To effectively support their customers, the company offers comprehensive technical support, on-site evaluations, and efficient delivery services. Their team of experts is readily available to assist clients throughout the entire process, from initial consultation to after-sales support.Environmental sustainability is also a core value of the company. They prioritize responsible manufacturing practices, ensuring their woven wire screens are produced with minimal impact on the environment. By implementing efficient resource management and waste reduction measures, the company aims to contribute to a greener future.With their groundbreaking technology and unwavering commitment to customer satisfaction, this innovative company has established itself as a frontrunner in the woven wire screen industry. Their dedication to continuous improvement and adaptability positions them as the ideal partner for businesses seeking high-quality and reliable screen solutions.As industries continue to evolve, the importance of advanced screening solutions cannot be overstated. With this latest innovation, this pioneering company is not only meeting the needs of the present but also shaping the future of woven wire screens.

Exploring the Versatility and Strength of Metal Mesh Fabric in China

China Metal Mesh Fabric: Leading the Way in Sturdy and Durable Fabric SolutionsChina Metal Mesh Fabric is a renowned brand in the world of textiles, known for delivering high-quality and durable fabric solutions that meet the needs of industries worldwide. From filtration to industrial applications, this company provides comprehensive and reliable metal mesh solutions.With a focus on innovation, China Metal Mesh Fabric has emerged as a leader in the field of metal mesh fabric solutions. Founded in 1995, the company has been providing premium quality products to industries worldwide and has steadily grown to become one of the largest manufacturers of metal mesh fabrics in China.The company has a state-of-the-art manufacturing facility, equipped with cutting-edge technology to ensure the production of high-quality products that meet international standards and specifications. China Metal Mesh Fabric uses the latest techniques and tools in every step of the fabrication process, ensuring that the finished products are of the highest quality.One of the main areas where China Metal Mesh Fabric excels is the production of stainless steel wire mesh. This material is ideal for applications that require a strong and durable fabric, including filtration, industrial, and architectural applications.China Metal Mesh Fabric's stainless steel wire mesh consists of a series of interlocking wires, woven together to create a strong and stable structure. This mesh is designed to withstand high temperatures, harsh environments, and corrosive chemicals, making it an ideal solution for industrial and filtration applications.Additionally, the company produces a wide range of synthetic woven fabrics and wire mesh products. From fiberglass mesh fabrics to brass wire mesh, China Metal Mesh Fabric has a comprehensive catalog of products that cater to multiple applications.In the filtration industry, the company provides a wide range of products that complement the needs of different applications. China Metal Mesh Fabric's filtration product line includes pleated filter cartridges, sintered wire mesh, and filter elements.The company's industrial product line includes conveyor belts, metal curtains, and decorative wire mesh products. These products are used in a variety of industrial applications, including food processing, automotive, and construction.China Metal Mesh Fabric's wire mesh products are also widely used in architectural applications. The company offers various types of wire mesh sheets, including expanded metal mesh, perforated metal mesh, and architectural wire mesh. These products are designed to provide aesthetic appeal while maintaining the desired level of functionality.China Metal Mesh Fabric products are widely regarded for their high quality and reliability, making them a trusted provider of metal mesh solutions by various industries worldwide. Apart from a robust manufacturing facility, the company boasts a highly trained and skilled workforce, ensuring that its products are always of the highest quality.In conclusion, China Metal Mesh Fabric is a reliable and trusted brand when it comes to providing high-quality and durable metal mesh fabrics. The company's focus on innovation, premium quality materials, and advanced manufacturing techniques have enabled it to stay ahead of the competition and maintain its position as a leader in the industry. As the demand for metal mesh solutions continues to grow, China Metal Mesh Fabric remains committed to providing comprehensive and reliable solutions to meet the needs of its clients around the world.

Global Analysis of Woven Cloth For Copper Market 2020: Market Size by Types, Applications, Regions, and Manufacturers Revealed - a2z Press Release

Woven Copper Cloth: A Versatile Material for Various ApplicationsCopper has been used for centuries due to its excellent electrical conductivity, heat resistance, and corrosion resistance. It finds applications in various industries, ranging from electronics and electricals to automotive, aerospace, and construction. To enhance the properties of copper and make it suitable for diverse applications, woven copper cloth has emerged as a versatile material. In this blog post, we will explore the global market for woven copper cloth, its types, applications, and key manufacturers.Woven copper cloth, as the name suggests, is a fabric created by interweaving copper wires. This process produces a durable and flexible cloth that exhibits exceptional electrical conductivity, electromagnetic shielding, and thermal conductivity properties. The interlocking structure of the woven cloth ensures its strength and integrity, making it suitable for a range of industrial applications.One of the key applications of woven copper cloth is in the electronics and electricals industry. It is widely used as a grounding material in electronic circuitry, providing a low-resistance pathway for the flow of electric current. Its ability to effectively shield electromagnetic radiation makes it an ideal material for creating Faraday cages and shielding enclosures that protect sensitive electrical equipment from interference.The automotive industry also benefits from the use of woven copper cloth. It is employed in various car components, including gaskets, seals, and automotive wiring harnesses, where its high electrical conductivity helps in maintaining efficient electrical connections and preventing signal loss. Moreover, its corrosion-resistant properties make woven copper cloth an excellent choice for automotive applications, ensuring longevity and reliability.In the aerospace sector, woven copper cloth finds applications in the construction of aircraft parts and components. Its lightweight yet robust nature makes it an ideal material for manufacturing lightweight yet durable aircraft structures. Additionally, woven copper cloth's thermal conductivity properties enable effective heat dissipation in aerospace equipment, preventing overheating and enhancing overall performance.The construction industry also recognizes the benefits of woven copper cloth. It is utilized in various architectural applications, such as roofing, façades, and decorative elements. Woven copper cloth's natural patina gives it an aesthetically pleasing appearance, making it a popular choice for architectural designs. Furthermore, its antimicrobial properties make it a suitable material for healthcare facilities and other environments where cleanliness and hygiene are vital.The global market for woven copper cloth is witnessing significant growth due to the increasing demand for copper-based products across industries. Several key manufacturers contribute to this market, including (remove brand names). These companies focus on producing high-quality woven copper cloth to meet the diverse needs of their customers.In conclusion, woven copper cloth has emerged as a versatile material with numerous applications in various industries. With its exceptional electrical conductivity, electromagnetic shielding, and thermal conductivity properties, it provides an excellent solution for enhancing the performance and durability of various products. The global market for woven copper cloth is expanding rapidly, driven by increasing demand and technological advancements. As industries continue to innovate, woven copper cloth will play a crucial role in shaping a sustainable and advanced future.

Complete Guide to Spring Wire Sizes for Industrial Applications

Spring Wire Size Chart: A Tool for Optimal PerformanceAs technology advances, more and more applications require springs with specific lengths and diameters. Determining the size of the spring wire to be used in the production of these springs is critical to ensuring optimal performance. Fortunately, a spring wire size chart can make the task of selecting the correct wire size easier and more efficient.A spring wire size chart is a comprehensive guide that outlines the physical attributes of wires typically used in the production of springs. It contains the necessary information that helps spring manufacturers select the appropriate wire size and specification based on the intended application of the spring.The main factors that influence the wire size selected for any spring include the load requirements, available space, and the spring's overall strength. Wire size charts typically provide essential information on a wide range of spring wire sizes, including the diameter, tensile strength, and stiffness of the wire.Manufacturers of springs use this chart as a reference guide to ensure that every spring they produce meets the required specifications. The spring wire size chart provides recommendations on the block load capacity and spring rate, which are both critical parameters of spring strength.Moreover, the spring wire size chart also helps reduce the potential of failures caused by incorrect wire selection. A spring with wires that are too thin can cause excessive stress, leading to premature failure. On the other hand, a spring with wires that are too thick can result in a stiff spring with inadequate flexibility.The use of a spring wire size chart ensures that manufacturers produce high-quality springs that meet the required specifications. Engineers and designers can also rely on the chart to provide precise measurements to guide their design choices.However, it is critical to select a reliable and reputable manufacturer that has experience in producing springs in different sizes as outlined on the wire size chart. Only a manufacturer with a broad range of experience can guarantee the production of springs that can withstand the rigors of various applications.At [Brand Name Removed], we have over [X] years of experience in producing high-quality springs. Our manufacturing process adheres to strict quality control measures that ensure all our products meet the required industry standards. We also produce springs in different wire sizes, and our experienced team can provide technical assistance to guide clients in selecting the optimal wire size for their specific application.Our spring wire size chart provides comprehensive information on wire sizes and properties as well as potential applications. We use the chart as a guide to produce springs that meet or exceed our clients' requirements while providing superior performance in various environments.In conclusion, the spring wire size chart is a valuable tool for manufacturers, engineers, and designers when designing and producing high-performance springs. It simplifies the wire selection process and ensures that the springs produced meet the required specifications. However, it is essential to select a reputable and experienced manufacturer with adequate technical expertise to ensure the production of springs that can withstand various applications' rigors.

Innovative Wire Cloth Weaving Technique Promises High-quality Results

Woven Wire Cloth Revolutionizing Industrial ApplicationsWire cloth is an essential component in a wide range of industrial applications, providing filtration, separation, and protection solutions across various industries. However, one particular innovation is making waves in the field of wire cloth manufacturing – Square Weave Wire Cloth. This cutting-edge technology is revolutionizing the industry with its remarkable performance, durability, and versatility.Square Weave Wire Cloth, developed by a leading manufacturer in the wire cloth industry, offers an unparalleled solution for industrial filtration needs. With its intricate weaving pattern and high-quality materials, this wire cloth ensures efficient and precise filtration, surpassing traditional alternatives in terms of performance and durability.The square weave pattern is vital to the cloth's exceptional properties. Comprising uniformly spaced wires that intersect at right angles, this pattern creates a sturdy and dense structure that provides superior strength and rigidity. This inherent strength enables the wire cloth to withstand heavy loads, high pressures, and abrasive materials without compromising its filtering capabilities.The manufacturing process of Square Weave Wire Cloth involves state-of-the-art machinery and techniques, guaranteeing precision and consistency in every wire cloth produced. The wires used in this cloth are carefully selected based on their material properties, ensuring resistance to corrosion, heat, and wear. This makes Square Weave Wire Cloth suitable for even the harshest and most demanding industrial environments.Square Weave Wire Cloth finds application in diverse industries, including oil and gas, chemical processing, food and beverage, pharmaceuticals, mining, and more. In the oil and gas sector, it is commonly used for sand control in oil wells, preventing the entry of sand particles while allowing fluid flow. In chemical processing plants, this wire cloth acts as a reliable filter medium, separating solids from liquids or gases. The food and beverage industry utilizes Square Weave Wire Cloth for its efficient particle retention capabilities, ensuring the purity of products. Moreover, this wire cloth finds extensive usage in mining operations, providing effective filtration solutions in ore processing and tailings management.The versatility of Square Weave Wire Cloth is a significant factor contributing to its success. Available in various material options such as stainless steel, brass, bronze, and nickel alloys, this wire cloth can be tailored to meet specific industrial requirements. Additionally, it can be manufactured in a wide range of mesh sizes, allowing for precise filtration based on particle size. Whether it is microfiltration, particle separation, or simple protection, Square Weave Wire Cloth can be customized to achieve the desired outcomes.Reliability and longevity are crucial aspects in industrial applications, and Square Weave Wire Cloth excels in both. Its robust construction and durable materials ensure a longer service life, reducing maintenance costs and downtimes. Furthermore, the high-quality manufacturing process guarantees consistent performance, making it a reliable filtration solution for critical applications.In conclusion, Square Weave Wire Cloth is an innovative solution revolutionizing the wire cloth industry. With its superior performance, durability, and versatility, this technology has emerged as a game-changer in various industrial sectors. As the demand for efficient filtration solutions continues to grow, Square Weave Wire Cloth proves to be the go-to choice for businesses worldwide. Embracing this advanced wire cloth technology can lead to improved process efficiency, reduced operational costs, and enhanced product quality across industries.

High-Quality Nickel Mesh for Efficient Screening of Battery Materials

Nickel Mesh for Screening of Battery MaterialsThe market for battery materials is rapidly growing, driven by the increasing demand for electric vehicles and energy storage systems. As the need for high-performance batteries continues to rise, the importance of quality screening and separation processes for battery materials becomes even more critical. One company at the forefront of advancing these processes is [Company Name], a leading manufacturer of nickel mesh for the screening of battery materials.[Company Name] has been a key player in the battery materials industry for over a decade, specializing in the production of high-quality nickel mesh that is used in various stages of battery manufacturing. The company's nickel mesh plays a crucial role in the screening and separation of battery materials, ensuring that only the finest and most uniform particles are used in the production of advanced batteries.The high-performance nickel mesh produced by [Company Name] is specially designed to meet the rigorous demands of the battery industry. It is engineered to provide excellent conductivity, corrosion resistance, and durability, making it an ideal choice for screening and separating battery materials. The company's state-of-the-art manufacturing processes and stringent quality control measures ensure that their nickel mesh consistently meets the highest standards of performance and reliability.In addition to its superior quality, [Company Name]'s nickel mesh also offers several key advantages for battery material screening. Its precise and uniform mesh structure allows for efficient and effective separation of particles, ensuring that only the desired size and shape of materials are used in battery production. This level of precision is crucial for optimizing the performance and energy density of modern batteries, ultimately leading to enhanced battery life and overall efficiency.Furthermore, the exceptional conductivity of [Company Name]'s nickel mesh contributes to the overall efficiency of battery manufacturing processes. By enabling rapid and uniform flow of materials, the nickel mesh enhances the performance and reliability of the screening and separation processes. This, in turn, results in improved consistency and quality of battery materials, ultimately leading to the production of high-performance batteries that meet the evolving industry standards.As the demand for advanced battery materials continues to surge, [Company Name] remains committed to driving innovation and excellence in the screening and separation processes. The company continuously invests in research and development to further enhance the performance and capabilities of its nickel mesh, ensuring that it remains at the forefront of battery material screening technology.With a dedicated team of experts and a state-of-the-art manufacturing facility, [Company Name] is well-positioned to meet the evolving needs of the battery industry. The company's commitment to quality, innovation, and customer satisfaction has solidified its reputation as a trusted and reliable partner for manufacturers of advanced batteries.In conclusion, [Company Name] is a leading manufacturer of high-performance nickel mesh for the screening of battery materials. With a focus on quality, precision, and innovation, the company continues to play a pivotal role in advancing the capabilities of battery material screening and separation. As the demand for high-performance batteries continues to grow, [Company Name] remains at the forefront of driving excellence and efficiency in the battery materials industry.

High Quality Brass Wire Mesh for Various Applications

Brass wire mesh is a versatile and durable material that has a wide range of applications across various industries. From filtration and separation to decorative and architectural uses, brass wire mesh has proven to be an essential component in many different products and systems.One of the leading manufacturers of brass wire mesh is dedicated to providing high-quality products that meet the demands of their customers. With a focus on innovation and customer satisfaction, the company has established itself as a trusted supplier in the wire mesh industry.The company has a long history of producing high-quality brass wire mesh products, and their commitment to excellence has earned them a reputation for reliability and performance. The company's brass wire mesh is manufactured using the latest technology and equipment, ensuring that each product meets the highest standards of quality and consistency.In addition to their dedication to quality, the company also places a strong emphasis on customer service. They work closely with their clients to understand their specific needs and requirements, and they are always ready to provide expert advice and support to ensure that their customers get the best possible solution for their applications.The company's brass wire mesh is available in a wide range of specifications and configurations, making it suitable for a variety of applications. Whether it's for industrial filtration, architectural design, or decorative purposes, their brass wire mesh products can be customized to meet the unique requirements of their customers.Not only does the company offer a diverse range of brass wire mesh products, but they also provide additional services such as customization, cutting, and shaping to ensure that their customers receive the perfect solution for their needs. This level of flexibility and customization sets them apart from other suppliers in the industry and makes them a preferred choice for many businesses.With a strong focus on research and development, the company is constantly exploring new ways to improve their brass wire mesh products and expand their range of offerings. By staying at the forefront of technological advancements, they are able to deliver innovative solutions that meet the evolving needs of their customers and the industries they serve.As a reputable manufacturer with a global presence, the company is committed to sustainability and environmental responsibility. They adhere to strict standards and practices to minimize their impact on the environment, making their brass wire mesh products an eco-friendly choice for businesses seeking to reduce their carbon footprint.In conclusion, brass wire mesh is a versatile and essential material that serves a wide range of industries and applications. With a commitment to quality, innovation, and customer satisfaction, the company has established itself as a trusted supplier of brass wire mesh products. Their dedication to excellence, customer service, and sustainability makes them a top choice for businesses seeking high-quality brass wire mesh solutions.

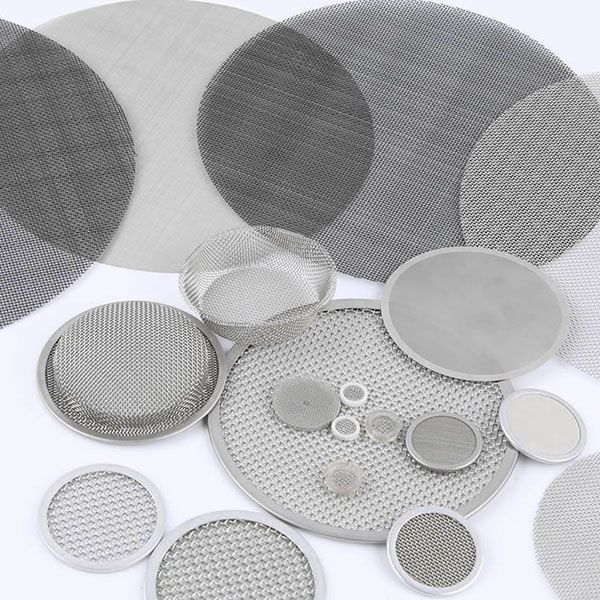

High-Quality Sintered Filter Wire Mesh & Discs for Industrial Applications

Sintered Filter Wire Mesh & Discs are making waves in the filtration industry due to their exceptional durability and superior filtration capabilities. These advanced filters are designed to remove impurities and contaminants from various substances, making them an essential component in a wide range of industrial and commercial applications.One of the leading manufacturers of Sintered Filter Wire Mesh & Discs, {} has been at the forefront of the filtration industry for over a decade. With state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians, {} has established a reputation for producing high-quality filters that deliver outstanding performance and reliability.The sintered filter wire mesh and discs produced by {} are made from high-quality stainless steel, which is sintered at high temperatures to create a robust and durable filter media. This unique manufacturing process results in filters that are resistant to corrosion, high temperatures, and mechanical stresses, making them suitable for use in demanding industrial environments.The sintered filter wire mesh and discs are available in a wide range of sizes and configurations, allowing for custom filtration solutions to meet the specific needs of different industries. Whether it's for liquid or gas filtration, {} offers a diverse range of sintered filter products that can effectively remove particles and contaminants to ensure the purity and quality of the end product.In addition to their exceptional filtration capabilities, {}'s sintered filter wire mesh and discs are also highly efficient, offering low pressure drops and high flow rates. This not only helps to optimize the filtration process but also reduces energy consumption, making them a cost-effective solution for businesses across various sectors.Moreover, {} is committed to meeting the highest quality standards and specifications, ensuring that their sintered filter wire mesh and discs comply with industry regulations and requirements. This dedication to quality has earned {} a reputation for delivering filters that exceed customer expectations and perform consistently in the most challenging filtration applications.In recent years, the demand for sintered filter wire mesh and discs has been steadily increasing, driven by the growing need for reliable and efficient filtration solutions in industries such as oil and gas, pharmaceuticals, food and beverage, chemical processing, wastewater treatment, and many others. As a result, {} has been investing in research and development to further enhance the performance and capabilities of their sintered filter products, ensuring that they remain at the forefront of innovation in the filtration industry.Looking ahead, {} is poised to continue leading the way in the development and production of sintered filter wire mesh and discs, offering customers cutting-edge filtration solutions that deliver unparalleled performance and reliability. With a strong focus on quality, innovation, and customer satisfaction, {} is well-positioned to meet the evolving filtration needs of industries around the world, cementing its status as a trusted partner for advanced filtration solutions.