Sintered Metal Filter Elements: The Best Solution for Filtration Needs

By:Admin

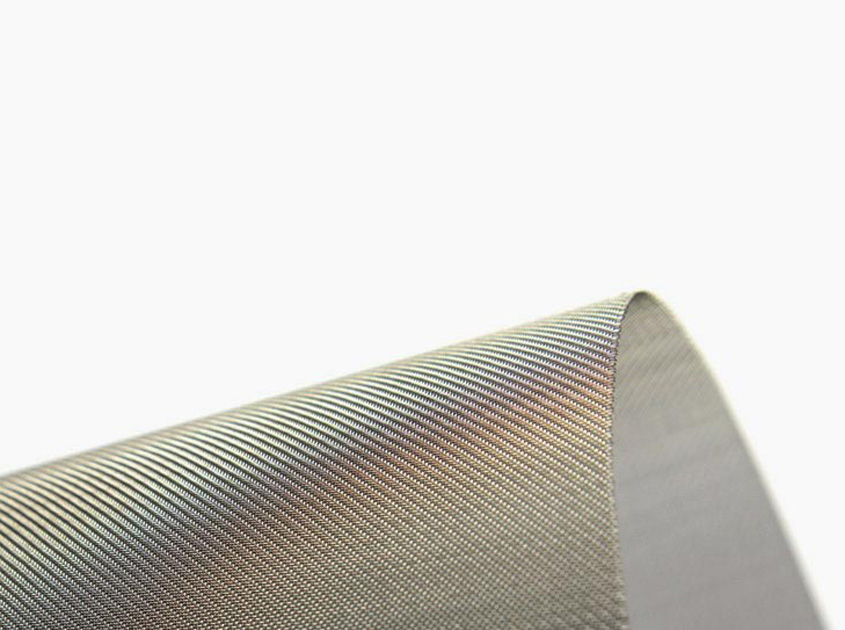

In today's industrial environment, the importance of filters cannot be overstated. Filters are an essential component of any manufacturing process as they help to prevent harmful particles from entering products during the production process. One such type of filter that has gained immense popularity in recent years is sintered metal filter elements. These elements are made up of sintered metal powders and are used in a variety of applications including liquid and gas filtration. In this article, we will discuss the benefits of using sintered metal filter elements, and introduce a company that specializes in manufacturing these high-quality products.

Benefits of Using Sintered Metal Filter Elements

One of the primary benefits of using sintered metal filter elements is their ability to withstand high temperatures. They are capable of withstanding temperatures ranging from -200 to 1000°C which makes them ideal for use in high-temperature applications. Additionally, these filter elements offer excellent resistance to corrosion and erosion. They are capable of working in harsh environments and are highly resistant to chemicals, acids, and bases.

Another advantage of sintered metal filter elements is their high filtration efficiency. They are designed to provide superior filtration and can capture even the smallest particles present in a liquid or gas medium. This makes them ideal for applications in the food and beverage industry where even the smallest impurities can cause contamination.

Sintered metal filter elements are also highly durable and long-lasting. They are made up of high-quality metal powders that are sintered together to form a strong, robust structure. This ensures that they can withstand high pressure and mechanical stress without compromising their filtration efficiency. Additionally, sintered metal filter elements are easy to clean and maintain which makes them a cost-effective solution for industrial filtration.

{} Company - A Leading Manufacturer of Sintered Metal Filter Elements

{} Company is a well-known name in the field of industrial filtration. The company has been designing and manufacturing sintered metal filter elements for over 30 years and is a leading supplier of these products worldwide.

{} Company's sintered metal filter elements are designed for high performance and are available in a variety of shapes, sizes, and materials to meet the specific needs of different industries. The company's product range includes sintered metal filter discs, filter cartridges, filter baskets, and filter plates.

{} Company has a state-of-the-art manufacturing facility equipped with advanced production equipment and technology. Their team of skilled engineers and technicians work tirelessly to ensure that each product is of the highest quality. {} Company is committed to providing its customers with the best products and services to meet their industrial filtration needs.

Conclusion

Sintered metal filter elements are an essential part of any industrial filtration process. Their ability to withstand high temperatures, resist corrosion and erosion, and provide high filtration efficiency makes them an ideal choice for a variety of industries. To ensure that you get the best quality sintered metal filter elements, it is essential to choose a reputable manufacturer like {} Company that has a proven track record of delivering high-quality products and exceptional service.

Company News & Blog

High-Pressure Filter Elements: Enhancing Filtering Efficiency

Title: Cutting-Edge High Pressure Filter Element Revolutionizes Filtration TechnologyIntroduction:In today's rapidly advancing industrial sector, businesses are constantly searching for innovative solutions to enhance operational efficiency, productivity, and environmental sustainability. Strengthening this quest further, an industry-leading company has recently unveiled its groundbreaking High Pressure Filter Element, poised to revolutionize the filtration technology landscape. By effectively removing contaminants from fluids under high-pressure circumstances, this cutting-edge filter element promises to deliver superior performance, exceptional quality, and unparalleled reliability across a wide range of industries.Main Body:1. The Need for Advanced Filtration Technology (100 words)In industries dealing with high-pressure fluid systems, such as oil and gas, automotive, manufacturing, and aerospace, the demand for robust and efficient filtration technology is paramount. Contaminants, such as particles, oil varnish, water, and other impurities, can greatly impact the performance and longevity of critical components. Hence, the introduction of the High Pressure Filter Element is a significant development, as it addresses these challenges with its advanced filtration capabilities.2. Unveiling the High Pressure Filter Element (150 words)Manufactured by a globally recognized company committed to technological advancements and customer satisfaction, the High Pressure Filter Element incorporates state-of-the-art design principles and cutting-edge materials. Its unique construction ensures exceptional strength, longevity, and unrivaled filtering performance, making it the ideal choice for high-pressure filtration applications. The innovative design consists of multiple layers of advanced filtration media that allow for efficient removal of contaminants without compromising fluid flow rates.3. Superior Performance and Efficiency (150 words)The High Pressure Filter Element has been extensively tested and validated to provide remarkable filtration efficiency, capable of removing particles as small as a few microns. This ensures that the filtered fluid meets or exceeds industry cleanliness specifications, safeguarding the integrity of vital equipment and reducing maintenance costs. The filter element's high dirt-holding capacity prolongs service intervals, resulting in improved operational uptime and reduced downtime. Moreover, its robust construction enables reliable operation even under extreme pressures and fluctuating conditions, ensuring consistent and high-quality filtration performance.4. Versatility and Customization Options (150 words)Recognizing the diverse needs of various industries, the High Pressure Filter Element offers a wide array of options and customization possibilities. Clients can choose from a range of filtration ratings, sizes, and configurations to match their specific requirements. With compatibility across multiple fluids, including hydraulic oils, lubricants, coolants, and process fluids, this versatile filter element caters to a broad range of applications. Additionally, advanced monitoring features such as pressure differential indicators and bypass valves can be incorporated to enhance the system's functionality and provide improved filter element change-out timelines.5. Environmental Sustainability and Cost Savings (150 words)Apart from its exceptional performance and versatility, the High Pressure Filter Element contributes significantly to environmental sustainability efforts. By effectively removing contaminants, it helps extend the service life of equipment, reducing the need for frequent component replacements, and minimizing waste generated from maintenance activities. As a result, businesses can experience substantial cost savings in terms of replacement parts, downtime, and disposal. Furthermore, the filter element's optimized design and advanced materials promote energy efficiency, ensuring that the filtration process consumes minimal power, which aligns with the company's commitment to reducing carbon footprints.Conclusion:The introduction of the High Pressure Filter Element heralds a new era in filtration technology, providing industries with a cutting-edge solution that delivers superior performance, exceptional quality, and unwavering reliability. This innovative filter element addresses the critical need for advanced filtration capabilities in high-pressure fluid systems, safeguarding equipment while reducing maintenance costs and environmental impact. With its versatility, customization options, and commitment to sustainability, this groundbreaking product promises to create a lasting impact on various industries, contributing to a more efficient, productive, and environmentally-conscious future.

High-Strength Brass Wire Mesh for Metal Power Filtration and Shielding

Brass Wire Mesh for Cabinets: Enhancing Metal Power Filtration and Shielding EfficiencyIn today's ever-evolving world, the importance of effective filtration and shielding solutions cannot be undermined. Whether in industrial settings or everyday household applications, ensuring that harmful particles and interference are kept at bay is crucial. In this regard, brass wire mesh has gained considerable recognition for its high strength, durability, and exceptional filtration capabilities. Moreover, when it comes to enhancing the functionality and aesthetics of cabinets, brass wire mesh emerges as an ideal choice for multiple reasons.Brass wire mesh with a 5 x 5 weave pattern has become a go-to option for many industries, including aerospace, filtration, automotive, and more. Offering an ideal balance between strength and flexibility, this mesh efficiently filters out fine particles, making it suitable for a wide range of applications. One of the primary advantages of using brass wire mesh for cabinets lies in its outstanding strength and tensile properties. This characteristic ensures that the mesh remains intact even under high pressure, providing long-lasting durability.The high strength and durability of brass wire mesh make it a reliable solution for metal power filtration. Cabinets, particularly those used in industrial settings, often encounter a variety of metallic particles, dust, and debris. These contaminants can not only impact the functionality of the enclosed equipment but can also jeopardize the safety of operators. By incorporating brass wire mesh into cabinet construction, industries can ensure a higher level of protection against such harmful elements, ultimately enhancing the overall productivity and efficiency of their operations.In addition to superior filtration capabilities, brass wire mesh also excels in shielding against electromagnetic interference (EMI). As technologies advance, EMI has become a growing concern in both industrial and residential environments. Unwanted interference can disrupt sensitive electronic equipment, leading to malfunctions, data corruption, or even critical failures. By integrating high-quality brass wire mesh into cabinet designs, manufacturers can effectively reduce EMI-related risks and enhance the reliability of the enclosed devices.From an aesthetic standpoint, brass wire mesh brings a touch of elegance and timelessness to cabinets. Its golden hue adds a unique visual appeal and blends seamlessly into various settings, whether traditional or contemporary. Moreover, brass wire mesh can be easily manipulated to fit different shapes and sizes, allowing for versatile customization options. This makes it an excellent choice for designers and architects seeking to create cabinets that not only prioritize functionality but also boast an eye-catching design.When sourcing brass wire mesh for cabinets, it is essential to ensure good quality. For this reason, it is advisable to rely on reputable suppliers who prioritize precision manufacturing and adhere to strict quality control measures. By procuring high-quality brass wire mesh, industries can be confident in the reliability and durability of their cabinets.In conclusion, brass wire mesh demonstrates immense potential in optimizing metal power filtration and shielding in cabinets. Its high strength, durability, and exceptional filtration capabilities make it an ideal choice for various industries and applications. Additionally, brass wire mesh offers aesthetic value, enhancing the visual appeal of cabinets. Incorporating brass wire mesh into cabinet designs allows for effective filtration, protection against EMI, and the creation of elegant and functional spaces. For manufacturers and designers seeking to optimize cabinet performance and aesthetics, brass wire mesh is unparalleled.

Crimped Wire Mesh: An Essential Guide to Understanding its Applications and Benefits

Title: Innovative Crimped Wire Mesh Revolutionizing Various IndustriesIntroduction:Wire mesh has long been recognized as one of the most versatile and widely used materials, finding applications in numerous industries. One particular innovation that is quickly gaining prominence is Crimped Wire Mesh, an advanced technology that offers enhanced durability, strength, and flexibility. This revolutionary product has opened up new possibilities in industries such as construction, mining, agriculture, and filtration, making it an increasingly popular choice across various sectors.1. Crimped Wire Mesh in the Construction Industry:With its unique crimping pattern and interlocking design, Crimped Wire Mesh has become an indispensable component in the construction industry. It is extensively used in reinforcement applications, concrete slabs, precast panels, and retaining walls. The robust and flexible nature of the mesh ensures structural integrity, while allowing for adequate ventilation and even distribution of stress. Additionally, its corrosion-resistant properties make it suitable for both interior and exterior applications, ensuring longevity and durability.2. Industrial Applications of Crimped Wire Mesh:The mining and quarrying industry greatly benefits from the use of Crimped Wire Mesh. It is utilized in screens for vibrating equipment, providing efficient separation and classification of various materials. The mesh's high tensile strength and resistance to abrasion make it ideal for demanding environments, where it can endure extreme temperatures and harsh operating conditions. Crimped Wire Mesh also finds application in heavy-duty shaker screens, sand control screens, and quarry meshing processes, ensuring efficient productivity and minimizing downtime.3. Agricultural Implementations of Crimped Wire Mesh:In the agricultural sector, Crimped Wire Mesh plays a vital role in maintaining productivity and protecting crops. It is widely used in livestock fencing, poultry cages, trellises, and fruit tree support systems. The mesh's corrosion resistance and robust construction allow for reliable and long-lasting use, with minimal maintenance requirements. Additionally, Crimped Wire Mesh provides excellent protection against pests and predators, ensuring the safety and well-being of animals and crops alike.4. Filtration and Sieving Applications:Crimped Wire Mesh is an essential component in various filtration and sieving processes across different industries. Its precise woven pattern allows for efficient particle separation and filtering, making it an ideal choice for water treatment facilities, pharmaceutical manufacturing, and food processing industries. The mesh can be customized to meet specific requirements, ensuring precise filtration, particle retention, and improved overall production quality.Conclusion:The innovation of Crimped Wire Mesh has revolutionized multiple industries by offering superior durability, strength, and flexibility. Its diverse applications in construction, mining, agriculture, and filtration have reshaped industry standards, allowing for improved efficiency and productivity. As the demand for this versatile material continues to grow, it is expected to find even more applications in emerging fields. With its many benefits, Crimped Wire Mesh is set to become a cornerstone in various industries, contributing to enhanced performance and long-term sustainability.

Innovative Copper Wire Mesh Enhancing Industrial Applications

Copper Wire Mesh: A Versatile Solution for Varied Industrial ApplicationsWith an increasing demand for durable and efficient materials in the industrial sector, copper wire mesh has emerged as a reliable and versatile solution. Renowned for its exceptional conductivity, corrosion resistance, and durability, copper wire mesh offers a wide range of applications across various industries.Copper wire mesh is primarily made from high-quality copper wires, intricately woven together to form a sturdy and flexible mesh. It consists of uniformly distributed square or rectangular openings, allowing for smooth airflow, filtration, and exceptional electrical conductivity. These unique properties make copper wire mesh an ideal choice for numerous industrial applications, such as filtration systems, shielding, ventilation, and many more.One of the key advantages of copper wire mesh is its exceptional corrosion resistance. Copper, being resistant to atmospheric oxidation, offers enhanced durability and long-term performance compared to other materials. This makes it a preferred choice for outdoor applications where exposure to harsh weather conditions is inevitable.Moreover, copper wire mesh possesses remarkable electrical conductivity, making it an excellent choice for electrical and electronics industries. It effectively prevents electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring smooth and uninterrupted signals in various electronic devices. This makes copper wire mesh an integral part of shielding applications, such as cables, enclosures, and housings for sensitive electronic components.Furthermore, copper wire mesh finds extensive use in the filtration industry. Its intricate weave structure allows for efficient filtration of solid particles and impurities from liquids and gases. Whether it is water filtration, oil filtration, or air purification, copper wire mesh offers excellent performance and ensures the purity and cleanliness of the filtered media.The versatility of copper wire mesh extends to the architectural and decorative industries as well. It is widely used for decorative purposes, as it adds a touch of elegance and sophistication to interiors and exteriors of buildings. Copper wire mesh can be fashioned into various shapes and forms, lending itself to artistic applications such as sculptures, wall paneling, and light fixtures.Another noteworthy application of copper wire mesh is in the agricultural industry. It finds utility in fencing applications, providing a secure boundary while allowing visibility and airflow. Its durability and corrosion resistance make it suitable for outdoor use and offer long-term protection for crops, livestock, and property.In addition to its functional applications, copper wire mesh also proves to be an eco-friendly solution. Copper is a natural resource and can be easily recycled, reducing the environmental impact caused by other synthetic materials. By choosing copper wire mesh, industries can contribute to sustainable development while enjoying its numerous benefits.As the leading provider of copper wire mesh, {Company Name} prides itself on delivering high-quality products that meet the diverse needs of industries worldwide. With state-of-the-art manufacturing facilities and a team of skilled professionals, we ensure that our copper wire mesh adheres to international quality standards and offers exceptional performance in every application.At {Company Name}, we continually strive for innovation and excellence. Our dedicated research and development team works tirelessly to enhance the durability, conductivity, and versatility of copper wire mesh, ensuring its effectiveness in various industries. Backed by our commitment to customer satisfaction and prompt delivery, we have established a solid reputation as a reliable supplier of copper wire mesh globally.In conclusion, copper wire mesh presents a multitude of benefits that make it an ideal choice for industries across the board. From its exceptional conductivity and corrosion resistance to its functional and decorative applications, copper wire mesh offers a versatile solution for a wide range of industrial needs. With the commitment to quality and customer satisfaction, {Company Name} is proud to be at the forefront of providing high-quality copper wire mesh to meet the diverse requirements of industries worldwide.

Discover a Comprehensive Directory of Woven Taffeta and Other Textile Fabrics

The world of textiles is a vast and diverse one, covering a multitude of fabrics used in a variety of industries. Among these fabrics is woven metal fabric, a material that has gained increasing popularity in recent times. In this article, we will take a closer look at woven metal fabric, its properties, applications, and the textile manufacturing industry as a whole.Woven metal fabric is a material made by weaving metal wires together. These wires can be made from a variety of metals such as stainless steel, bronze, and aluminum, among others. The weaving process can be done using traditional methods or advanced machinery, depending on the desired outcome and purpose of the fabric.One of the most notable properties of woven metal fabric is its durability and strength. Due to its metal composition, this fabric can withstand high temperatures, harsh weather conditions, and resist corrosion. Its strength makes it ideal for use in various applications such as architectural, industrial, and even in fashion.In architecture, woven metal fabric is used for its decorative properties as well as its functionality. It can be used to create stunning facades and as cladding for buildings, adding an elegant and modern touch to any structure. It can also be used for sun control, providing shade while allowing natural light to filter through.In industrial settings, woven metal fabric is used for filtration, where it can be used in the creation of filters for gas and liquid processing and separation. It is also used in conveyor systems, as it can withstand heavy loads and resist wear and tear.In fashion, woven metal fabric has been used for a variety of purposes, including clothing, jewelry, and accessories. It can be woven into intricate patterns and shapes and used to create stunning pieces that are both functional and stylish.The textile manufacturing industry is a vast and complex one, covering a multitude of fabrics used in various industries such as fashion, architecture, and industrial applications. In textile manufacturing, fabrics are created using a variety of methods such as weaving, knitting, and finishing.The woven metal fabric is created using a weaving method, where metal wires are interlaced together to form a pattern. The weaving process can be done using traditional methods or advanced machinery, depending on the desired outcome and purpose of the fabric.The textile manufacturing industry also covers a multitude of fabrics, including taffeta and other woven and knit fabrics. These fabrics are used for various applications and purposes, from clothing to home decor to industrial uses.In conclusion, woven metal fabric is a unique and versatile material that has gained increasing popularity in recent times due to its durability, strength, and versatility. Its use in architecture, industrial applications, and even in fashion has made it a sought-after material. As the textile manufacturing industry continues to evolve and expand, the use of fabrics such as taffeta, knit, and woven metal fabric will continue to be essential in various applications and industries.

Discover the Benefits of Using Stainless Steel Wire Mesh for Mosquito Netting

Title: Revolutionary Mosquito Net Design Promises Fuss-Free Protection for Better SleepSubtitle: Introducing a breakthrough in mosquito net technology that combines safety, durability, and convenience.[City, Date] - In a bid to combat the widespread issue of mosquito-borne diseases, {Company Name}, a renowned leader in the field of residential and commercial mosquito net solutions, is excited to unveil their latest innovation - the SS Wire Mesh Mosquito Net. This revolutionary product aims to revolutionize the way people protect themselves against mosquitoes, providing a convenient and effective solution for improved sleep and overall well-being.With mosquito-borne diseases posing a significant threat to public health, particularly in tropical and subtropical regions, the SS Wire Mesh Mosquito Net is set to become an essential household item. This state-of-the-art net combines cutting-edge design, high-quality materials, and advanced engineering techniques to create a formidable barrier against disease-carrying mosquitoes.At the heart of the SS Wire Mesh Mosquito Net is its superior construction. Crafted from premium stainless steel wire mesh, this net offers unparalleled durability and resistance to wear and tear. The micro-fine aperture of the mesh ensures that even the tiniest insects are effectively prevented from entering, providing users with robust protection throughout the night.One of the standout features of the SS Wire Mesh Mosquito Net is its hassle-free installation process. Designed with user convenience in mind, the net can be effortlessly fitted to a variety of windows, doors, and even beds, thanks to its customizable dimensions and user-friendly installation kit. This innovative design eliminates the need for professional assistance, making it an ideal solution for homes, hotels, guesthouses, and classrooms.Unlike traditional mosquito nets, the SS Wire Mesh Mosquito Net eliminates the constant need for readjustment and maintenance. Its sturdy frame and well-engineered fasteners ensure that once installed, the net remains securely in place, allowing for uninterrupted sleep and peace of mind. This unique design is particularly beneficial for families with young children, as it eliminates the risk of accidental entanglement.In addition to its durability and ease of installation, the SS Wire Mesh Mosquito Net also addresses the concerns of ventilation and natural light. Its high-quality mesh material provides excellent air circulation, ensuring the net does not compromise the comfort of those inside. Natural light can still filter through, creating a pleasant ambience while maintaining a barrier against mosquitoes.{Company Name} has long been a trusted provider of mosquito net solutions, known for the quality and effectiveness of their products. With the introduction of the SS Wire Mesh Mosquito Net, the company aims to further solidify its position as a leader in the industry. Their commitment to continuous improvement and customer satisfaction is a driving force behind this transformative innovation.Excited about the potential of the SS Wire Mesh Mosquito Net, {Company Name}'s spokesperson highlighted its numerous advantages: "Our new mosquito net design is a game-changer when it comes to convenience and reliability. With this innovation, we hope to encourage individuals and families to prioritize their health and safety by making mosquito protection hassle-free."As mosquito-borne diseases continue to plague communities worldwide, it's crucial to stay one step ahead. The SS Wire Mesh Mosquito Net promises to provide an effective solution to this age-old problem, ensuring a peaceful and restful environment for all. With its revolutionary design, durability, convenience, and hassle-free installation, this product offers an unparalleled level of protection, giving individuals and families the peace of mind they deserve.About {Company Name}:{Company Name} is a leading provider of premium mosquito net solutions for residential and commercial use. With a focus on continuous innovation and customer satisfaction, the company aims to improve the quality of life by offering effective protection against mosquito-borne diseases. Their range of mosquito nets is designed to be durable, easy to install, and aesthetically pleasing, catering to the diverse needs of customers worldwide.For more information about {Company Name} and its products, please visit {company website}.Contact:{Contact Name}{Designation}{Contact Number}{Email Address}{Company Website}

Understanding Wire Cloth in Automotive Applications: Definition and Importance Discussed

Wire Cloth in Automotive Applications: Understanding the Role of Molybdenum (Mo) Wire ClothWire cloth is a popular material used in different industrial applications. It consists of a matrix of interlaced and interconnected wires, designed to provide strength, durability, and filtration properties. In the automotive industry, wire cloth is used in various components, such as air filters, oil filters, fuel filters, and exhaust systems.One of the key benefits of wire cloth in automotive applications is its ability to filter different types of impurities and contaminants that may negatively affect the performance and efficiency of the engine. For example, air filters made of wire cloth can prevent dust, dirt, and other airborne particles from entering the engine's combustion chamber, which can lead to reduced power, fuel economy, and increased emissions.Similarly, oil filters that incorporate wire cloth can trap metal shavings, dirt, and other impurities that may accumulate in the engine oil, ensuring optimal lubrication and preventing premature wear and tear. Fuel filters with wire cloth can also prevent dirt, rust, and other contaminants from entering the fuel system, which can cause engine stalling, decreased performance, and potential safety hazards.Another use of wire cloth in automotive applications is in the exhaust system. Wire cloth can be used as a catalytic converter substrate, providing a large surface area for the chemical reactions that convert harmful pollutants into less harmful compounds. In this case, the selection of the right type of wire cloth is critical to ensure optimal gas flow and conversion efficiency.When it comes to wire cloth for automotive applications, one of the most important factors to consider is the material composition. In particular, the inclusion of molybdenum (Mo) in the wire cloth can provide significant advantages in terms of strength, durability, and corrosion resistance.Molybdenum is a refractory metal that has excellent resistance to high temperatures, corrosion, and wear. When added to wire cloth, it enhances the material's properties, making it suitable for challenging conditions and applications. For example, molybdenum wire cloth is ideal for use in high-temperature environments, such as exhaust systems, where it can withstand the harsh conditions and maintain its structural integrity.Molybdenum wire cloth is also highly resistant to corrosion, making it suitable for use in corrosive environments, such as marine applications. Additionally, it has excellent wear resistance, which can extend the lifespan of the wire cloth and reduce maintenance costs.In conclusion, wire cloth is a versatile material that plays a crucial role in various automotive applications. Its unique properties, such as filtration, strength, and durability, make it suitable for different components, such as air filters, oil filters, fuel filters, and exhaust systems. When it comes to selecting wire cloth for automotive applications, the inclusion of molybdenum (Mo) can provide significant benefits in terms of high-temperature resistance, corrosion resistance, and wear resistance. By choosing the right wire cloth for your automotive application, you can ensure optimal performance, efficiency, and durability.

Discover the Widest Selection of Crypto Mining Accessories for Sale in South Africa

Title: A Complete Guide to Stainless Steel Hardware Cloth for Cryptocurrency MiningIntroduction:Cryptocurrency mining has gained significant popularity in recent years. As more individuals and businesses look to profit from this digital revolution, the demand for reliable and efficient mining hardware has skyrocketed. In this blog, we will explore the significance of stainless steel hardware cloth in the realm of cryptocurrency mining. Whether you're a beginner or a seasoned miner, this comprehensive guide will provide invaluable insights into the benefits and applications of this essential accessory.Understanding the Need for Cryptocurrency Mining Hardware:Cryptocurrency mining involves the process of solving complex mathematical algorithms to verify and validate transactions on a blockchain network. This process requires powerful hardware, capable of performing intensive computations. As the mining industry continues to evolve, so does the need for advanced equipment that offers enhanced durability, efficiency, and security.Introducing Stainless Steel Hardware Cloth:Stainless steel hardware cloth, also known as wire mesh or wire netting, is a versatile accessory used in various industries. Its sturdy construction and resistance to corrosion make it an ideal choice for cryptocurrency mining hardware. Stainless steel hardware cloth acts as a protective layer, preventing unwanted intrusions while allowing optimal airflow and ventilation to maintain the temperature integrity of mining rigs.Benefits of Stainless Steel Hardware Cloth for Cryptocurrency Mining:1. Enhanced Security: The durable nature of stainless steel hardware cloth ensures that your mining rigs are adequately protected from physical damage and unauthorized access. Its small, closely spaced openings effectively deter pests and prevent them from causing disruptions.2. Optimal Airflow and Ventilation: Mining rigs generate a significant amount of heat. Stainless steel hardware cloth promotes efficient airflow, reducing the risk of overheating and prolonging the lifespan of your mining equipment. The spacious design of the cloth allows proper ventilation, preventing the accumulation of dust and debris.3. Corrosion Resistance: The high-quality stainless steel used in hardware cloth offers exceptional resistance to corrosion, ensuring long-term durability even in harsh environments. This resistance is crucial for miners operating in areas with high humidity or extreme temperatures.4. Versatility: Stainless steel hardware cloth is available in various mesh sizes, wire gauges, and dimensions, making it compatible with different mining setups. It can be custom-tailored to meet specific requirements, providing miners with flexibility and ease of installation.Applications of Stainless Steel Hardware Cloth in Cryptocurrency Mining:1. Mining Enclosures: Stainless steel hardware cloth is commonly used as a protective barrier around mining rigs, ensuring adequate airflow and ventilation while offering unparalleled security.2. Rack Covers: By using stainless steel hardware cloth as a rack cover, miners can safeguard their valuable mining equipment from unwanted contact or material accumulation.3. Air Filtration Systems: Incorporating stainless steel hardware cloth into air filtration systems helps trap dust and other particles, preventing them from clogging sensitive mining components.4. Power Supply Protection: Cryptocurrency mining rigs rely heavily on power supply units. Employing stainless steel hardware cloth as a protective layer can prevent accidental contact or damage to these critical components.Conclusion:In the dynamic and competitive world of cryptocurrency mining, investing in the right hardware and accessories can significantly impact your success. Stainless steel hardware cloth offers unparalleled benefits in terms of security, airflow, ventilation, and corrosion resistance. Whether you are a mining enthusiast or a professional miner, prioritizing the protection and prolonged lifespan of your valuable mining equipment is paramount. Explore the wide range of stainless steel hardware cloth options available and secure your mining infrastructure today!Disclaimer: This blog is intended for informational purposes only and should not be considered as financial or investment advice.

Durable and Versatile Copper Mesh Cloth: A Practical Solution for Numerous Applications

Title: Innovative Copper Mesh Cloth Revolutionizes Industries, Paving the Way for Sustainable SolutionsIntroduction:Innovation is at the core of the modern world, paving the way for sustainable solutions that address environmental, social, and economic challenges. One such groundbreaking innovation is Copper Mesh Cloth, a versatile material that has transformed numerous industries. In this article, we shed light on the remarkable features of Copper Mesh Cloth and explore its impact on various sectors globally. I. Understanding Copper Mesh Cloth:Copper Mesh Cloth, a revolutionary material developed by a leading industrial solutions provider, combines the unique properties of copper with an intricate cloth structure. This innovative design creates a durable, flexible, and electrically conductive mesh, opening up a world of possibilities for different applications. The mesh is comprised of copper threads woven together to create a seamless and efficient fabric.II. Environmental Applications:1. Air Filtration Systems: Copper Mesh Cloth's antimicrobial and antiviral properties make it ideal for air filtration systems. It effectively traps microorganisms, dust particles, and allergens, ensuring clean air circulation in sensitive environments such as hospitals, laboratories, and manufacturing units.2. Water Filtration Systems: The mesh's ability to capture and remove impurities and bacteria from water has made it a game-changer in the water purification industry. Copper Mesh Cloth enables the development of sustainable and eco-friendly water filtration systems that are both effective and durable.III. Industrial Applications:1. Electrical Conductivity: Copper is renowned for its exceptional electrical conductivity. Thus, Copper Mesh Cloth finds extensive use in electrical and electronic industries as connectors, grounding systems, and electromagnetic shielding. Its durability and flexibility make it an ideal choice for complex wiring systems in automobiles, aerospace, and telecommunications.2. Heat Exchange Components: The exceptional thermal conductivity of copper makes Copper Mesh Cloth an ideal material for heat exchange components, such as heat sinks and heat exchangers. It efficiently transfers heat from high-temperature sources and dissipates it, resulting in enhanced energy efficiency and extended equipment lifespan.IV. Agriculture and Pest Control:1. Pest Deterrence: Copper Mesh Cloth, when installed in buildings or around plants, acts as an effective barrier against rodents, insects, and other pests. Its durability, resistance to corrosion, and malleability make it easy to install and maintain in agricultural and residential settings.2. Organic Crop Protection: Copper's natural antimicrobial properties have been acknowledged for centuries. Copper Mesh Cloth provides organic farmers with an effective and sustainable solution to combat various crop diseases, thereby reducing the need for harmful chemical pesticides.V. COVID-19 Mitigation:1. Face Masks: Copper Mesh Cloth has gained attention during the COVID-19 pandemic due to its antimicrobial properties. It is being used as a filter material in high-quality masks, capable of trapping and neutralizing viruses and bacteria more effectively than traditional filters.2. Touch-Surface Coatings: The antimicrobial properties of Copper Mesh Cloth also make it suitable for coatings on frequently touched surfaces, such as doorknobs, handrails, and elevator buttons. This reduces the risk of germ transmission in public spaces, promoting safer environments.Conclusion:Copper Mesh Cloth has transformed numerous industries through its versatility, durability, and unique properties. Its applications range from air and water filtration to electrical conductivity and pest control. Moreover, it has proven instrumental in combatting the COVID-19 pandemic by providing efficient solutions for face masks and touch-surface coatings. As the world increasingly embraces sustainable and innovative solutions, Copper Mesh Cloth stands as a beacon of hope, promising a brighter and cleaner future for all.

High-Quality Stainless Steel Wire Cloth for Various Applications

Title: Aisi304 Stainless Steel Wire Cloth: A Versatile Solution for Reliable FiltrationIntroduction:In an era where industries are constantly evolving and innovating, the search for reliable and durable filtration solutions remains crucial. Recognizing this need, an industry-leading company has introduced Aisi304 Stainless Steel (SS) Wire Cloth, a remarkable product that offers exceptional functionality across various applications. With its impeccable quality and impressive performance capabilities, Aisi304 SS Wire Cloth has quickly emerged as a preferred choice among professionals worldwide.1. Understanding Aisi304 Stainless Steel:Aisi304 Stainless Steel is a grade of steel widely known for its excellent corrosion resistance, durability, and versatility. The Aisi304 SS Wire Cloth, specifically manufactured utilizing this grade of steel, inherits these invaluable qualities. This wire cloth is meticulously woven, comprising a grid-like structure of interlacing wires, resulting in a robust mesh.2. Unmatched Application Capabilities:Aisi304 SS Wire Cloth is renowned for its diverse range of applications, owing to its exceptional characteristics. Its superior corrosion resistance, high heat resistance, and remarkable tensile strength make it an ideal choice for various industries. Notably, its applications span across sectors such as oil and gas, chemical processing, pharmaceuticals, mining, food processing, water filtration, and many more.3. Advantages of Aisi304 SS Wire Cloth:a) Enhanced Durability: Aisi304 SS Wire Cloth is designed to withstand harsh environmental conditions, ensuring longevity and longevity for long-lasting performance.b) Corrosion Resistance: The inherent stainless steel composition of the wire cloth renders it highly resistant to rust, corrosion, and oxidization, even in aggressive environments.c) Optimal Filtration: The precisely woven structure of Aisi304 SS Wire Cloth exhibits uniform mesh sizes that enable efficient filtration, ensuring the removal of impurities without compromising flow rates.d) High Tensile Strength: The exceptional tensile strength of the wire cloth guarantees resistance to mechanical stress, reducing the risk of breakage or deformation during installation or operation.e) Chemical Compatibility: Aisi304 SS Wire Cloth exhibits excellent resistance to a wide range of chemicals, making it suitable for filtration requirements involving corrosive substances.4. Industry-Specific Applications:a) Oil and Gas: Aisi304 SS Wire Cloth plays a vital role in oil extraction processes, protecting crucial equipment from contaminants and providing efficient separation of solid and liquid phases.b) Chemical Processing: The wire cloth's resistance to corrosion and chemical compatibility make it an excellent choice for chemical filtration, ensuring purity and preventing equipment damage.c) Pharmaceuticals: With stringent quality requirements, the pharmaceutical industry utilizes Aisi304 SS Wire Cloth to filter out contaminants from liquids, ensuring safety and consistency in production.d) Mining: Wire cloth screens, made from Aisi304 SS Wire Cloth, are widely used in mining operations, enabling efficient separation and sizing of ores and minerals.e) Food Processing: Aisi304 SS Wire Cloth is an indispensable component in the food processing industry, ensuring hygiene and filtering out impurities from liquids and solids.5. Conclusion:The introduction of Aisi304 SS Wire Cloth has revolutionized filtration systems, offering unparalleled performance across a wide range of industries. Its superior corrosion resistance, durability, and versatility make it the go-to choice for professionals worldwide. As industries continue to evolve, rely on the durability and efficiency of Aisi304 SS Wire Cloth to meet your filtration needs.