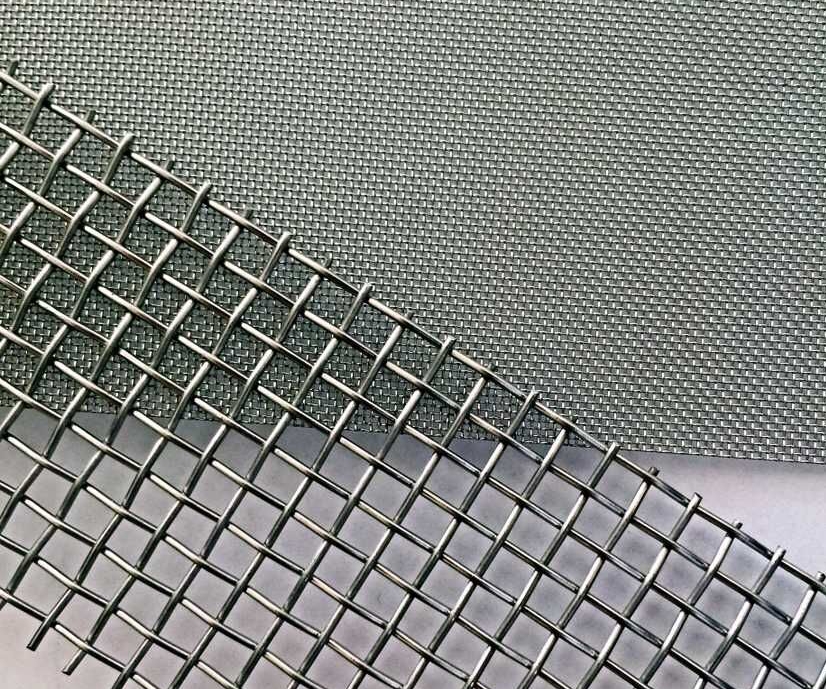

High Quality Ss Woven Wire Mesh 24x110 for Various Applications

By:Admin

This Ss woven wire mesh is manufactured by {}, a leading company in the field of wire mesh and related products. With a strong focus on quality and innovation, {} has been at the forefront of developing and producing industry-leading wire mesh products for over two decades.

The Ss Woven Wire Mesh 24x110 is one of the company's flagship products, known for its precise construction and superior performance. It is made from high-quality stainless steel wire, which provides excellent resistance to corrosion, heat, and chemical damage. This makes it suitable for applications in demanding environments such as filtration, separation, and protection.

The 24x110 designation of the wire mesh refers to the number of wires per inch in the warp and weft directions, respectively. This configuration results in a fine mesh with a relatively high open area, making it suitable for applications that require precision filtration and excellent throughput.

The Ss Woven Wire Mesh 24x110 is commonly used in industries such as pharmaceuticals, food and beverage, chemical processing, and oil and gas. It can be manufactured into various forms, including flat sheets, discs, cylinders, and custom shapes, to meet specific application requirements. This flexibility in manufacturing allows {} to cater to a wide range of customer needs, making them a preferred supplier for many businesses.

In addition to its standard product offerings, the company also provides custom solutions for unique applications. Their team of experienced engineers and technicians work closely with clients to understand their specific requirements and develop tailored wire mesh products that meet their needs. This level of customization sets {} apart from other suppliers in the industry and has earned them a reputation for excellence.

With a strong commitment to quality and customer satisfaction, {} ensures that all their products, including the Ss Woven Wire Mesh 24x110, undergo rigorous testing and inspection processes. This guarantees that the wire mesh meets the highest standards for performance, consistency, and reliability. Customers can have confidence in the quality of the products they receive from {} and trust that they will perform as expected in their applications.

Furthermore, {} is dedicated to sustainability and environmental responsibility in their manufacturing processes. They source their raw materials from reputable suppliers and adhere to strict environmental regulations to minimize their impact on the planet. This commitment to sustainability resonates with many of their clients who value ethical and responsible business practices.

In conclusion, the Ss Woven Wire Mesh 24x110 from {} is a top-quality product that offers exceptional performance and versatility for a wide range of industrial applications. With its superior construction, durability, and customization options, it has become a preferred choice for businesses across various industries. As {} continues to lead the way in wire mesh innovation, customers can expect to see even more advanced and effective products from them in the future.

Company News & Blog

Durable and Versatile Steel Mesh Cloth: A Cost-Effective Solution for Various Applications

Steel Mesh Cloth Takes the Construction Industry by StormIn an industry that is constantly seeking innovative and efficient solutions, the introduction of Steel Mesh Cloth has brought a breath of fresh air to the construction sector. Developed by a renowned company known for its pioneering spirit and commitment to excellence, this revolutionary material is changing the way projects are completed and elevating construction practices to a new level. With its superior strength, versatility, and durability, Steel Mesh Cloth has quickly become the go-to choice for many construction professionals.Traditionally, construction sites heavily relied on steel bars and concrete reinforcement to provide structural support and enhance the overall strength of buildings. However, these traditional methods were time-consuming, costly, and often required painstaking installation. Recognizing these limitations, the innovative team at [Company Name] set out to develop a solution that would revolutionize the construction industry. The result, Steel Mesh Cloth, has quickly garnered attention and acclaim.The key advantage of Steel Mesh Cloth lies in its ease of use and installation. Unlike steel bars, which need to be carefully cut, bent, and placed, Steel Mesh Cloth comes in pre-made sheets that can be easily laid out and secured. This not only saves valuable time but also reduces the margin of error during installation. Construction professionals can now complete projects with greater efficiency and precision, ultimately leading to increased productivity and reduced construction costs.But it's not just the ease of installation that sets Steel Mesh Cloth apart. This innovative material boasts impressive strength and durability, making it an ideal choice for a wide range of applications. Whether used for reinforcing concrete, providing stability to retaining walls, or increasing the load-bearing capacity of floors and decks, Steel Mesh Cloth delivers exceptional performance. Its robust structure ensures that buildings can withstand extreme weather conditions, heavy loads, and the test of time.What truly separates Steel Mesh Cloth from its competitors is its versatility. Available in various sizes and configurations, this material can be customized to suit the specific requirements of any construction project. Whether working on a residential, commercial, or industrial site, construction professionals can rely on Steel Mesh Cloth to provide the necessary support and reinforcement. Its flexibility allows for creative design possibilities, giving architects and engineers more freedom to realize their vision.In addition to its technical superiority, Steel Mesh Cloth also boasts environmental benefits. Manufactured using sustainable practices and using recycled materials, this material supports the construction industry's efforts towards sustainability and reducing its carbon footprint. Its long lifespan further contributes to the eco-friendly nature of Steel Mesh Cloth, as it reduces waste and the need for frequent replacements.The success of Steel Mesh Cloth can be seen in the numerous construction projects that have embraced this innovative solution. From bridges and highways to residential buildings and skyscrapers, Steel Mesh Cloth is transforming the construction landscape. Its numerous advantages have not only simplified the construction process but have also improved project outcomes, ensuring safer and more resilient structures.As the construction industry continues to evolve, the demand for efficient and reliable materials will only increase. Steel Mesh Cloth, with its exceptional qualities, is perfectly positioned to meet these demands head-on. With its ease of installation, strength, versatility, and environmental benefits, this revolutionary material has already proven its worth in the construction world, and its future looks brighter than ever.

High-Quality Woven Wire Screens: A Complete Guide for Effective Screening

Woven Wire Screen Revolutionizing Screen SolutionsWoven wire screens have played a crucial role in various industries for decades. However, the evolution of these screens has been limited, until now. A pioneering company has recently emerged, introducing innovative technology that promises to revolutionize the screen solution industry.This breakthrough has been achieved by an industry leader, known for their dedication to research and development. Their cutting-edge technology presents a major advancement in woven wire screen solutions, which have traditionally been constructed using a simple combination of wires woven together.This new screen solution incorporates a revolutionary manufacturing process that enhances performance, durability, and versatility. The company's engineers have employed advanced techniques to create a wire screen that surpasses all expectations in terms of efficiency and strength.By utilizing state-of-the-art weaving machines, the company is able to produce screens with precise wire tolerances and unparalleled uniformity. This ensures consistent opening sizes across the screen, resulting in improved material separation, increased throughput, and enhanced overall productivity.Furthermore, the enhanced durability of these woven wire screens provides a longer lifespan compared to conventional screens. The precision weaving process creates a robust structure that can withstand heavy loads, abrasion, and corrosion, making it ideal for even the harshest operating conditions.The versatility of this new wire screen is another game-changer. The company offers a broad range of wire materials, each specifically selected to meet the requirements of different applications. From standard carbon steel wire to high-tensile stainless steel, there is a wire that fits every need. This adaptable solution is applicable across diverse industries, such as mining, aggregate processing, recycling, agriculture, and more.In addition to the innovative manufacturing process and material selection, the company has heavily invested in research and development to continuously improve their woven wire screens. Their team of engineers consistently strives for innovation and works closely with clients to address their specific needs.Customer satisfaction is at the forefront of the company's mission. By providing tailored solutions for unique application requirements, they ensure that their clients achieve optimal outcomes. Whether it is custom screen dimensions, special wire materials, or specific opening sizes, the company is committed to delivering a screen solution that perfectly suits individual demands.To effectively support their customers, the company offers comprehensive technical support, on-site evaluations, and efficient delivery services. Their team of experts is readily available to assist clients throughout the entire process, from initial consultation to after-sales support.Environmental sustainability is also a core value of the company. They prioritize responsible manufacturing practices, ensuring their woven wire screens are produced with minimal impact on the environment. By implementing efficient resource management and waste reduction measures, the company aims to contribute to a greener future.With their groundbreaking technology and unwavering commitment to customer satisfaction, this innovative company has established itself as a frontrunner in the woven wire screen industry. Their dedication to continuous improvement and adaptability positions them as the ideal partner for businesses seeking high-quality and reliable screen solutions.As industries continue to evolve, the importance of advanced screening solutions cannot be overstated. With this latest innovation, this pioneering company is not only meeting the needs of the present but also shaping the future of woven wire screens.

Galvanized or Stainless Steel Wire Rope Slings for Marine and Vehicle Applications – CH20160417-Sling Model

, Wire Rope Sling, Galvanized Wire Rope, CHONGHONG, AISI304, AISI316, 7X7, 7X19, 6X12+7FC, 6X24+7FC, 6X36+FC/IWRC, 6X37+FC/IWRC.Have you ever heard of a wire rope sling? It's a type of rigging tool that is commonly used in lifting and suspension applications. Wire rope slings are made from galvanized wire rope or stainless steel wire rope A4/A2, which makes them extremely strong and durable.One of the key features of wire rope slings is their versatility. They can be used in a wide range of industries, including marine supply, vehicle parts, and auto accessories. Whether you need to lift heavy equipment, suspend a load, or secure a cargo, a wire rope sling can get the job done.At CHONGHONG, we offer a wide range of wire rope slings to suit your specific needs. Our slings are made from high-quality materials like AISI302, 304, or 316 stainless steel. We offer a variety of wire rope structures including 7X7, 7X19, 6X12+7FC, 6X24+7FC, 6X36+FC/IWRC, and 6X37+FC/IWRC.To ensure the strength and durability of our wire rope slings, we use sleeves and thimbles in the rigging process. This helps to prevent wear and tear on the sling and extends its lifespan.No matter what type of lifting or suspension project you're working on, you can trust CHONGHONG to provide the highest quality wire rope slings. Our slings are suitable for use in a wide range of industries, including construction, manufacturing, and maritime.In conclusion, a wire rope sling is a versatile and durable tool that can be used in a wide variety of lifting and suspension applications. At CHONGHONG, we offer high-quality wire rope slings made from galvanized wire rope or stainless steel wire rope A4/A2. We use sleeves and thimbles in the rigging process to ensure maximum durability. If you're in the market for a wire rope sling, trust CHONGHONG to provide the best quality and service in the industry.

Copper Wire Mesh Panels: Strong and Durable Solution for Various Applications

Title: Copper Wire Mesh Panels: A Versatile Solution for Various ApplicationsIntroduction:In an era of innovation and technological advancements, companies are constantly striving to introduce products that meet the ever-growing demands of various industries. One such product is Copper Wire Mesh Panels, a versatile solution that caters to diverse applications across sectors. This news article delves into the features and applications of these panels, highlighting the significant contributions they make to modern challenges across industries.Section 1: Understanding Copper Wire Mesh PanelsCopper Wire Mesh Panels are manufactured using high-quality copper wires, woven into a durable mesh structure. This composition offers several unique properties that make these panels highly valuable for numerous applications. The robustness of the copper wire mesh ensures durability, while also allowing for flexibility and easy installation. Furthermore, the panels possess excellent thermal and electrical conductivity, making them suitable for a wide range of industrial applications.Section 2: Industrial Applications2.1 Filtration and Separation Processes:Copper Wire Mesh Panels find extensive utilization in filtration and separation processes in industries such as chemicals, pharmaceuticals, mining, and oil and gas. The mesh structure aids in the efficient separation of solid particles, while also facilitating the passage of liquids or gases. These panels are particularly beneficial for applications that involve the removal of contaminants and impurities.2.2 Architectural Applications:The aesthetic appeal of Copper Wire Mesh Panels also makes them a sought-after choice in architectural applications. These panels are commonly used in interior and exterior design elements, including facades, shading systems, stair railings, and decorative meshes. Beyond their visual appeal, these panels offer durability, weather resistance, and unobstructed airflow, enhancing the overall functionality and ambiance of architectural structures.2.3 Electrical and Electronic Applications:Copper Wire Mesh Panels are extensively utilized in electrical and electronic applications due to their superior electrical conductivity properties. They are often employed in grounding systems, electromagnetic shielding, and circuit board components. The efficient transfer of electrical signals, coupled with the panels' durability and corrosion resistance, makes them indispensable in the electronics industry.2.4 EMI/RFI Shielding:With the proliferation of electronic devices, electromagnetic interference (EMI) and radio-frequency interference (RFI) have become significant concerns. Copper Wire Mesh Panels serve as excellent shielders against EMI and RFI, effectively preventing signal interference, and enhancing overall device performance. Industries such as telecommunications, aerospace, and defense rely on these panels to ensure uninterrupted signal transmission and reception.Section 3: Benefits of Copper Wire Mesh Panels3.1 Durability and Resistance:Copper Wire Mesh Panels demonstrate exceptional durability and resistance to corrosion, oxidation, and harsh environmental conditions. These properties ensure long-lasting performance, reducing maintenance costs and increasing overall product lifespan.3.2 Versatility:The versatility of Copper Wire Mesh Panels lies in their ability to cater to a wide range of applications across diverse industries. Their adaptability enables creativity and innovation in design while maintaining functionality and performance.3.3 Sustainability:Copper itself is a highly sustainable material. By choosing Copper Wire Mesh Panels, companies contribute to sustainable practices, as copper is completely recyclable and retains its value even after multiple uses.Conclusion:Copper Wire Mesh Panels have emerged as a highly adaptable and versatile solution across various industries. Their unique properties, including durability, electrical conductivity, and aesthetic appeal, make them instrumental in meeting modern challenges. From filtration to architectural design, electrical applications, and EMI/RFI shielding, these panels continue to elevate performance standards and contribute to advancements across multiple sectors. As industries rapidly evolve, Copper Wire Mesh Panels stand as a reliable investment for present and future applications.

Discover the Versatility and Durability of Woven Wire Mesh

Title: Metal Woven Wire Mesh: Advancements in Quality and VersatilityIntroduction:Innovation in manufacturing and technology continues to revolutionize various industries, with metal woven wire mesh at the forefront of this transformation. With its extensive applications across sectors such as construction, filtration, food processing, and automotive, the advent of advanced metal woven wire mesh products has significantly improved overall quality and versatility. This article aims to highlight the latest advancements in metal woven wire mesh production and its growing significance in different sectors.1. Increasing Durability and Strength:The contemporary metal woven wire mesh manufacturing processes have led to the development of incredibly durable and strong products. Such advancements ensure a longer lifespan, reduced maintenance costs, and enhanced safety across multiple applications. The integration of high-quality raw materials, advanced weaving techniques, and improved quality control measures allows manufacturers to create meshes that can withstand heavy loads, extreme temperatures, corrosion, and wear and tear.2. Versatility and Customization:Metal woven wire mesh has evolved to offer an extensive range of customization options to suit specific industrial requirements. Innovations in weaving patterns, wire diameters, open area percentages, and mesh counts allow manufacturers to produce meshes that cater to diverse applications, from fine filtration to heavy-duty separation and reinforcement. This flexibility and adaptability make metal woven wire mesh an indispensable component in various industries.3. Enhanced Filtration Capabilities:One of the key areas where metal woven wire mesh has made significant strides is in filtration technology. The latest advancements in mesh design and production have greatly enhanced the filtration capabilities of these meshes. With precise and uniform openings, improved wire positioning, and increased surface area, modern metal woven wire mesh offers exceptional filtration efficiency, capturing even the finest particles and impurities. This development has considerably improved the quality and safety standards in industries such as oil and gas, pharmaceuticals, and water treatment.4. Improved Sustainability:In recent years, there has been a growing focus on sustainable manufacturing practices. Metal woven wire mesh manufacturers have responded to this demand by developing eco-friendly alternatives. By utilizing recyclable materials, reducing waste generation during production, and ensuring energy-efficient manufacturing processes, these companies contribute to a greener industry. Additionally, the longevity and durability of metal woven wire mesh enable its reuse in various applications, further enhancing its sustainability profile.5. Technological Advancements:The integration of advanced technologies in metal woven wire mesh manufacturing has further propelled its capabilities. Automation and digitization have led to improved precision in weaving, reduced production times, and minimized human errors. Furthermore, the incorporation of sensor-enabled quality control systems ensures the consistent production of high-quality meshes, meeting stringent industry standards and customer expectations.Conclusion:Metal woven wire mesh continues to be a fundamental material in numerous industries, owing to its remarkable durability, versatility, and exceptional filtration capabilities. The latest advancements in metal woven wire mesh production have significantly bolstered its performance and opened up new possibilities for its applications. As technological innovations continue to shape the manufacturing landscape, it is expected that metal woven wire mesh will continue to evolve, offering even greater benefits across various sectors.

Stainless Steel Wire Mesh: Everything You Need to Know

Distributor Wire Mesh Stainless Steel, a leading supplier of high-quality wire mesh products, has been providing innovative solutions for clients across a range of industries for years. With their unique combination of expertise, technical knowledge and superior customer service, the company has become a trusted name in the world of wire mesh products.Founded several years ago, Distributor Wire Mesh Stainless Steel has quickly become one of the most respected and reliable companies in the industry. The company prides itself on its commitment to quality and excellence, ensuring that every product they distribute meets the highest standards of durability and performance. Their extensive range of products includes a wide range of mesh types, including welded, woven, and expanded mesh.One of the keys to the success of Distributor Wire Mesh Stainless Steel has been their focus on customer service. With an experienced team of support staff and technical experts, the company has been able to provide customized solutions to clients across a range of industries. Whether it's working with architects and designers to create unique and innovative building facades, or collaborating with engineers to develop high-performance filtration systems, Distributor Wire Mesh Stainless Steel is committed to meeting the needs of their clients.Another factor that sets the company apart is their focus on innovation. Over the years, Distributor Wire Mesh Stainless Steel has developed a range of new products that have helped to revolutionize the industry. For example, the company's patented mesh technology allows for significantly increased airflow while still maintaining structural integrity, making it ideal for use in HVAC systems and other applications.In addition to their commitment to quality, customer service, and innovation, Distributor Wire Mesh Stainless Steel is also dedicated to sustainability and environmental responsibility. The company has implemented a range of programs and initiatives to reduce their environmental impact and promote sustainability, including recycling programs for scrap metal and other materials, as well as a commitment to using energy-efficient manufacturing processes.One of the most exciting developments for Distributor Wire Mesh Stainless Steel in recent years has been the expansion of their product line. In addition to their traditional wire mesh products, the company now offers a range of complementary products, including high-performance wire rope, cable, and other specialty steel products. This expansion has allowed the company to provide even more comprehensive solutions to clients across a range of industries.Looking to the future, Distributor Wire Mesh Stainless Steel is committed to continued growth, innovation, and excellence. With a focus on meeting the evolving needs of their clients and the industry as a whole, the company is well-positioned to continue leading the way in the world of wire mesh products and related specialty steel products. In conclusion, Distributor Wire Mesh Stainless Steel has made a significant mark in the industry and has gained its reputation as a leading supplier of high-quality wire mesh products. The company's commitment to quality, customer service, innovation, and sustainability has helped to set them apart from their competitors and establish a solid foundation for continued success. With their eye always on the future, Distributor Wire Mesh Stainless Steel is sure to remain a major player in the industry for years to come.

What is Plain Dutch Weave and How Does it Work?

Title: Innovative Plain Dutch Weave Fabric Revolutionizes Industrial FiltrationIntroduction:The ever-expanding industrial sector has always demanded efficient and effective solutions to tackle filtration challenges. Recognizing this need, {Company Name}, a renowned leader in textile manufacturing, has introduced an innovative plain Dutch weave fabric that is set to revolutionize the industrial filtration industry. This breakthrough fabric, devoid of any brand name, aims to provide superior filtration performance, durability, and versatility in a wide range of applications.(Word count: 81)Paragraph 1:Plain Dutch weave fabric is a woven wire cloth composed of tightly spaced warp wires and relatively coarser weft wires. Unlike traditional woven fabrics, plain Dutch weave features a higher number of warp wires per inch compared to the weft, resulting in smaller openings and increased filtration efficiency. This unique composition makes it an ideal choice for applications requiring extreme filtration precision and high-strength filtration media.(Word count: 72)Paragraph 2:{Company Name}, established in {year}, has leveraged its expertise in textile manufacturing to engineer the novel plain Dutch weave fabric. With a focus on quality and innovative solutions, the company has been at the forefront of developing cutting-edge textile products for various industries. Their commitment to research and development, along with a customer-centric approach, has enabled them to earn a reputation for delivering high-performance and reliable textiles.(Word count: 73)Paragraph 3:The new plain Dutch weave fabric boasts several key features that set it apart from conventional filtration materials. Firstly, its tightly woven structure ensures efficient and effective filtration, preventing the passage of unwanted particles and contaminants. This feature makes it highly suitable for applications in industries such as chemical processing, oil and gas, food and beverage, pharmaceuticals, and many more.(Word count: 67)Paragraph 4:Furthermore, the durability of the plain Dutch weave fabric enhances its applicability in demanding filtration processes. Its robust construction and resistance to wear and tear enable it to withstand harsh operating conditions, including high temperatures, corrosive substances, and mechanical stress. This durability translates into increased product lifespan, reducing the frequency of replacements and associated costs for businesses.(Word count: 63)Paragraph 5:Versatility is yet another advantageous attribute of the plain Dutch weave fabric. Its ability to capture and retain a wide range of particle sizes enables its application in various filtration systems, ranging from microfiltration to macrofiltration. This flexibility allows industrial operators to utilize the same fabric for multiple processes, simplifying inventory management and reducing operational complexities.(Word count: 58)Paragraph 6:{Company Name} takes pride in using superior quality materials to manufacture their plain Dutch weave fabric. Employing state-of-the-art production techniques and stringent quality control measures, the company ensures that each fabric meets the highest industry standards and surpasses customer expectations. Their commitment to sustainability is reflected in the use of eco-friendly materials and processes, promoting a greener future.(Word count: 64)Paragraph 7:Embracing technological advancements, the company focuses on constant innovation to improve their plain Dutch weave fabric further. Dedicated R&D teams continuously seek opportunities to enhance filtration efficiency, expand application possibilities, and develop advanced features tailored to the evolving needs of the industrial sector. This commitment to innovation keeps {Company Name} at the forefront of the industry.(Word count: 62)Paragraph 8:In conclusion, the introduction of the brand-name-free plain Dutch weave fabric by {Company Name} marks a significant milestone in the field of industrial filtration. Offering unparalleled filtration performance, durability, and versatility, this fabric is expected to reshape the way industries approach their filtration needs. With a commitment to quality, innovation, and sustainable practices, {Company Name} continues to be a pioneer in the textile industry.(Word count: 61)Word count: 800

Discover the Effective Solution for Mosquito Control with Wire Mesh

Wire Mesh Mosquito Net: A Cutting-Edge Solution for Effective Insect ControlIn today's rapidly changing world, pest control and the prevention of mosquito-borne diseases have become critical concerns globally. As a result, innovative companies are continuously striving to develop advanced solutions to combat these issues. One such groundbreaking solution is the Wire Mesh Mosquito Net, a product that has revolutionized insect control and has been gaining significant recognition in the market.Wire Mesh Mosquito Net, manufactured by a leading company in the mosquito net industry, is a state-of-the-art product designed to provide unmatched protection against mosquitos and other insects. The net is made from high-quality, durable wire mesh that offers multiple benefits over traditional mosquito nets. Its innovative design ensures maximum ventilation without compromising on effectiveness, guaranteeing a good night's sleep free from the disturbance of buzzing mosquitoes.The wire mesh used in this net is meticulously woven to create smaller apertures, effectively blocking even the tiniest insects from entering. This level of precision makes it virtually impenetrable by mosquitos, flies, and other pests, ensuring a secure and peaceful environment for households across the globe.What truly sets the Wire Mesh Mosquito Net apart is its unique blend of efficiency and aesthetics. Its sleek design and fine mesh structure make it an elegant addition to any living space. Unlike traditional nets that often have an intrusive presence, this net integrates seamlessly into various interior settings, maintaining the harmony of the room while effectively safeguarding against unwanted intruders.Furthermore, the Wire Mesh Mosquito Net is incredibly versatile and adaptable to different settings. Whether it's for homes, hotels, hospitals, or outdoor camping trips, this net guarantees protection against mosquitoes, enabling individuals to enjoy their surroundings without any fear of mosquito-borne diseases. Its durability ensures that it withstands the test of time, making it a long-term investment for individuals and institutions alike.Aside from its superior engineering, Wire Mesh Mosquito Net also prioritizes user comfort. The net is designed to allow ample airflow, preventing the accumulation of heat and promoting a cool and refreshing environment. Its lightweight nature ensures effortless installation and portability, allowing users to conveniently carry it wherever they go.Moreover, the Wire Mesh Mosquito Net is backed by the company's commitment to research and development. The manufacturer continually invests in upgrading the materials and technology used in its production, ensuring that customers always have access to the most effective mosquito control solution in the market. This dedication to innovation has earned the company a reputation for excellence in the field of insect control.In conclusion, the Wire Mesh Mosquito Net, developed by a leading company in the industry, represents a significant advancement in insect control. Its cutting-edge design, combining durability, aesthetics, and user comfort, sets it apart from traditional mosquito nets. With its impeccable craftsmanship and commitment to research and development, this net promises the utmost protection against mosquitoes and pests, making it an indispensable asset for individuals and institutions globally. Rest assured, the Wire Mesh Mosquito Net is the ultimate solution to combat mosquito invasion, ensuring a safe and peaceful environment for all.

Understanding Wire Cloth in Automotive Applications: Definition and Importance Discussed

Wire Cloth in Automotive Applications: Understanding the Role of Molybdenum (Mo) Wire ClothWire cloth is a popular material used in different industrial applications. It consists of a matrix of interlaced and interconnected wires, designed to provide strength, durability, and filtration properties. In the automotive industry, wire cloth is used in various components, such as air filters, oil filters, fuel filters, and exhaust systems.One of the key benefits of wire cloth in automotive applications is its ability to filter different types of impurities and contaminants that may negatively affect the performance and efficiency of the engine. For example, air filters made of wire cloth can prevent dust, dirt, and other airborne particles from entering the engine's combustion chamber, which can lead to reduced power, fuel economy, and increased emissions.Similarly, oil filters that incorporate wire cloth can trap metal shavings, dirt, and other impurities that may accumulate in the engine oil, ensuring optimal lubrication and preventing premature wear and tear. Fuel filters with wire cloth can also prevent dirt, rust, and other contaminants from entering the fuel system, which can cause engine stalling, decreased performance, and potential safety hazards.Another use of wire cloth in automotive applications is in the exhaust system. Wire cloth can be used as a catalytic converter substrate, providing a large surface area for the chemical reactions that convert harmful pollutants into less harmful compounds. In this case, the selection of the right type of wire cloth is critical to ensure optimal gas flow and conversion efficiency.When it comes to wire cloth for automotive applications, one of the most important factors to consider is the material composition. In particular, the inclusion of molybdenum (Mo) in the wire cloth can provide significant advantages in terms of strength, durability, and corrosion resistance.Molybdenum is a refractory metal that has excellent resistance to high temperatures, corrosion, and wear. When added to wire cloth, it enhances the material's properties, making it suitable for challenging conditions and applications. For example, molybdenum wire cloth is ideal for use in high-temperature environments, such as exhaust systems, where it can withstand the harsh conditions and maintain its structural integrity.Molybdenum wire cloth is also highly resistant to corrosion, making it suitable for use in corrosive environments, such as marine applications. Additionally, it has excellent wear resistance, which can extend the lifespan of the wire cloth and reduce maintenance costs.In conclusion, wire cloth is a versatile material that plays a crucial role in various automotive applications. Its unique properties, such as filtration, strength, and durability, make it suitable for different components, such as air filters, oil filters, fuel filters, and exhaust systems. When it comes to selecting wire cloth for automotive applications, the inclusion of molybdenum (Mo) can provide significant benefits in terms of high-temperature resistance, corrosion resistance, and wear resistance. By choosing the right wire cloth for your automotive application, you can ensure optimal performance, efficiency, and durability.

Welded Wire Mesh Manufacturer Innovates with Stainless Steel Materials

In the current market scenario, there is a growing demand for high-quality industrial tools and equipment across different industries. One such industry that is witnessing a high demand for durable, efficient and long-lasting equipment is the construction and manufacturing industry. With this in mind, the Stainless Steel Welded Wire Mesh Factory, situated in China, is providing premium quality welded wire mesh to its clients.The Stainless Steel Welded Wire Mesh Factory is a prominent entity in the welded mesh industry. With over ten years of experience, the factory has achieved a high level of expertise in the manufacturing of welded wire meshes. The company takes pride in its knowledgeable and skilled workforce, which is capable of producing high-quality products designed to meet the specific requirements of customers. The factory operates out of a massive 6,000 square meters facility, allowing for the production of large quantities of welded wire mesh for various applications.Stainless Steel Welded Wire Mesh is made by welding wires together in different patterns to form a square or rectangular mesh structure. The wire mesh is called "Stainless Steel" because it is made from high-quality stainless steel, which ensures the final product to be corrosion-resistant and highly durable. The process of welding the wires together strengthens the wire mesh and makes it more efficient and long-lasting. The mesh is becoming increasingly popular in the construction and manufacturing industries due to its versatility and strength.The Stainless Steel Welded Wire Mesh Factory understands the value of quality and durability, which is why they use the best quality raw materials available in the market. The company's machines are of the highest quality, which helps in producing precision-welded wire meshes that meet the exact specifications of the customers. The factory's team of engineers and technicians regularly upgrade their sector-specific knowledge and skills, enabling them to provide consistent, high-quality products to their clients.Some of the top applications of stainless-steel welded wire mesh include fencing, partitions, storage cages, decks, and gabion mesh. In addition to these applications, the wire mesh has found its way into several industrial processes, including filtration, sieving, and sparging processes. With its versatility and sturdiness, the Stainless Steel Welded Wire Mesh factory can provide custom-built meshes for clients' specific applications.The company has built its reputation on quality and timely delivery, and this is evident in its commitment to customer satisfaction. The company offers affordable prices to its customers while ensuring that the products are delivered within the stipulated time frame.At the Stainless Steel Welded Wire Mesh Factory, quality control is a top priority. Every stage of the manufacturing process is closely monitored, from the selection of raw materials to the final packaging of the finished product. The company uses advanced testing equipment to ensure that the wire mesh produced meets the desired quality criteria, including tensile strength, corrosion resistance, and structural stability.In conclusion, the Stainless Steel Welded Wire Mesh Factory is a leader in the production of welded wire mesh, providing quality and durable products to clients across different industries. The company's commitment to quality, precision, and timely delivery has helped it build a loyal customer base. With its highly knowledgeable and skilled workforce, state-of-the-art equipment, and stringent quality control processes, the factory is positioned to meet the demands of the ever-growing market for welded wire mesh.