- Home

- Blog

- Metal Mesh Fabric Factory: Exploring the Versatility and Applications of Metal Mesh Fabrics

Metal Mesh Fabric Factory: Exploring the Versatility and Applications of Metal Mesh Fabrics

By:Admin

[City, Date] - Metal Mesh Fabric Factory, a leading manufacturer of high-quality metal mesh fabrics, is thrilled to announce its expansion plans to meet the growing demand for its innovative products. The company, known for its commitment to quality and customer satisfaction, aims to increase its production capacity in order to cater to a wider range of industries and clients.

With over [number] years of experience in the industry, Metal Mesh Fabric Factory has established itself as a reliable and trusted supplier of metal mesh fabrics. The company prides itself on its state-of-the-art manufacturing facilities, highly skilled workforce, and dedication to excellence. Its products, made from the finest quality materials, have gained popularity across industries such as architecture, automotive, fashion, and more.

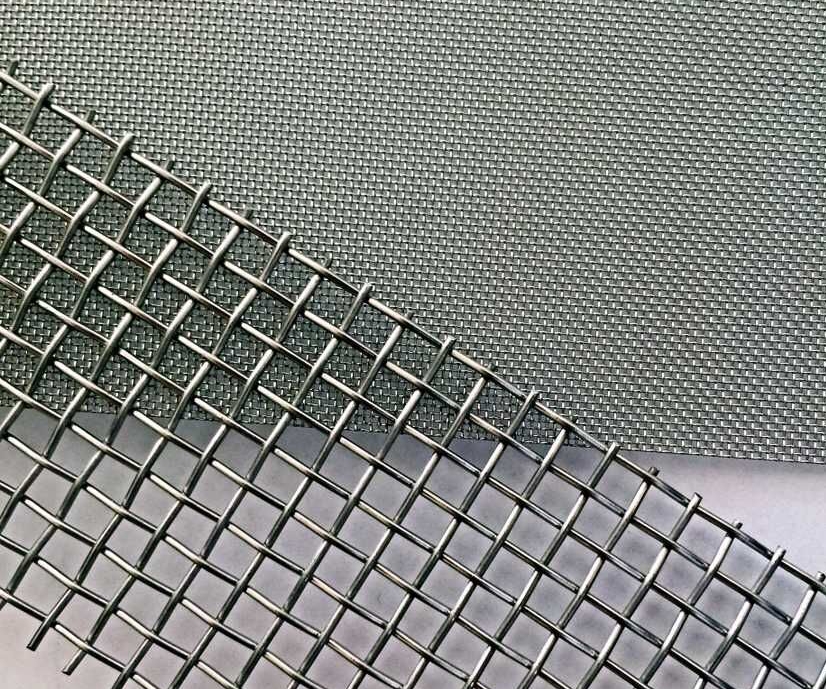

Metal Mesh Fabric Factory's metal mesh fabrics offer a unique combination of strength, durability, and aesthetic appeal. The fabrics are intricately woven with high-quality metal wires, providing them with exceptional strength while maintaining a visually appealing design. This versatility makes them suitable for a wide array of applications such as wall cladding, interior decoration, sun protection, sound insulation, and filtration.

Recognizing the increasing demand for metal mesh fabrics, Metal Mesh Fabric Factory has decided to invest in expanding its production capacity. The expansion plan includes the acquisition of state-of-the-art machinery and equipment, as well as the recruitment and training of additional skilled personnel. These strategic investments will enable the company to significantly increase its production output, ensuring faster turnaround times and meeting bulk order requirements.

The market for metal mesh fabrics is experiencing rapid growth, and Metal Mesh Fabric Factory aims to take full advantage of this opportunity by diversifying its product offerings. The company plans to introduce new designs, patterns, and finishes to cater to the evolving needs and preferences of its customers. With a dedicated research and development team, Metal Mesh Fabric Factory is constantly exploring innovative techniques and materials to enhance the performance and aesthetics of its products.

Metal Mesh Fabric Factory values its relationships with its clients and strives to provide exceptional customer service at every stage of the process. From initial consultations and product selection to installation support and after-sales service, the company goes above and beyond to ensure customer satisfaction. Its commitment to quality and reliability has earned it a loyal customer base, and the expansion plans are expected to further strengthen these relationships.

In addition to meeting the growing demand for metal mesh fabrics, Metal Mesh Fabric Factory also aims to contribute to the local economy through job creation and community engagement. The expansion plans will generate employment opportunities for skilled individuals, contributing to the overall growth and development of the region. The company also plans to engage in corporate social responsibility initiatives, focusing on environmental sustainability and community welfare.

As Metal Mesh Fabric Factory prepares for its expansion, it remains dedicated to upholding its core values of quality, innovation, and customer satisfaction. The company's ability to evolve and adapt in the face of changing market demands positions it as a leader in the industry. With its expanded production capacity and diverse range of products, Metal Mesh Fabric Factory is poised to meet the growing needs of its customers and continue its trajectory of success.

About Metal Mesh Fabric Factory:

Established over [number] years ago, Metal Mesh Fabric Factory is a leading manufacturer of high-quality metal mesh fabrics. The company specializes in the production of strong, durable, and visually appealing metal mesh fabrics for various industries. With a commitment to quality and customer satisfaction, Metal Mesh Fabric Factory has gained a reputation for excellence and reliability. For more information, please visit [website].

Contact:

[Contact Person]

[Contact Designation]

[Company Name]

[Address]

[Phone Number]

[Email Address]

Company News & Blog

How Woven Mesh is Revolutionizing the Industrial Market

Brass Woven Mesh: The New Age Solution for Industrial ProcessesMesh wire materials have been utilized in various industries for centuries. Their versatile nature has led to their application in numerous industrial processes. In the present times, the use of mesh wires has become more pronounced than ever before, and the credit goes to the innovation that has led to the modern-day mesh wire materials. One such wire mesh type that has gained popularity in recent years is brass woven mesh.Brass woven mesh is a type of mesh wire material formed by weaving brass wires together. The weaving process involves interlacing wires at right angles to form a square grid pattern. The size and shape of the mesh determine its application. Brass woven mesh materials are known for their corrosion-resistant and durable properties. Besides, the mesh's lustrous golden finish offers an aesthetic appeal, making it suitable for various applications. The wire mesh is often used as a filter or sieve in industries such as petrochemical, pharmaceutical, and food processing.One company that has gained recognition for producing high-quality brass woven mesh materials is based in China. The company prides itself on providing its customers with top-notch quality wire mesh materials that exceed their expectations. The company's production process involves high-tech machinery, coupled with skilled professionals who work tirelessly to ensure that the products leave their facility in optimal condition. Their brass woven mesh products are available in various sizes, hence meeting their customers' diverse needs.The brass woven mesh produced by this Chinese company has found numerous applications across various industries globally. For instance, in the petrochemical industries, the mesh is used as oil and gas filters. Its corrosion-resistant properties ensure that the mesh can withstand harsh environments that are common in the petrochemical sector. In addition, the mesh's fine size ensures that it sieves out small particles that may contaminate the oil and gas mixtures.In the pharmaceutical industry, brass woven mesh is used in the production of capsules. The mesh used for capsules production is characterized by a high-quality sieve, which ensures that the capsules do not have any foreign particles. Brass woven mesh's non-toxic nature makes it a suitable alternative to other material types commonly used in the production process.Moreover, brass woven mesh is widely used in the food processing industry. The mesh's unique properties make it ideal for use in the production of sieves and strainers. As a result, it is commonly used to sieve solids from liquids or separate liquids from one another. Its food-grade certification means that it is safe to use with food, minimizing the risk of contamination.Furthermore, the company produces brass woven mesh materials for decorative purposes. The mesh's golden luster makes it a suitable material for various crafting projects. Its durability makes the mesh a popular choice among jewelers as it can be shaped into various forms without losing its aesthetic appeal.Providing high-quality brass woven mesh materials requires adopting strict quality control measures that ensure the adherence to international standards. The Chinese company has adopted such measures and regularly undergoes quality inspections by external auditors to guarantee that its products meet market requirements.The company has a diverse customer base, ranging from small businesses to major corporations across various industries. Its customer-centric approach ensures that customer satisfaction is always on the forefront. This has enabled the company to build long-term relationships with its clients while attracting new ones.In conclusion, brass woven mesh materials have become an essential item in various industrial processes. The incorporation of brass wires and advanced weaving technology has made them reliable, durable, and versatile. The Chinese company has become recognized for producing high-quality brass woven mesh materials that exceed customer's expectations. Its production process involves high-tech machinery and skilled professionals that guarantee top-notch products. As more industries continue to adopt advanced manufacturing processes, there is no doubt that brass woven mesh materials will play a crucial role in ensuring the production process's success.

Hot Dipped Galvanized Welded Wire Mesh: Material, Characteristics

Welded wire mesh, also known as welded mesh, is a type of wire product that has been welded together at the intersection of the wires. This type of wire mesh is typically made from low carbon steel wire, stainless steel wire, or galvanized wire.One of the most popular forms of welded wire mesh is hot-dipped galvanized welded wire mesh. This type of welded mesh is produced from low carbon steel wire that has been welded together and then treated with a hot-dipped galvanizing process. This process involves dipping the welded wire mesh into a bath of molten zinc, which coats the mesh in a corrosion-resistant layer of zinc that helps to protect it from rust and other forms of corrosion.One of the main characteristics of hot-dipped galvanized welded wire mesh is its strength and durability. Because the wires are welded together at the intersections, the resulting mesh is much stronger and more resistant to bending and breaking than other types of wire mesh. Additionally, the hot-dipped galvanizing process adds an extra layer of protection that makes the welded wire mesh resistant to rust and other forms of corrosion.Another important characteristic of hot-dipped galvanized welded wire mesh is its versatility. This type of mesh can be used in a wide range of applications, including construction, agriculture, and fencing. It can be cut to different sizes and shapes, and can be used to create a variety of different structures and barriers.When it comes to choosing the right type of hot-dipped galvanized welded wire mesh, one of the most important considerations is the wire size. In general, a wire mesh with a smaller wire size will be stronger and more durable, while a mesh with a larger wire size will be more pliable and easier to handle.If you're looking for high-quality hot-dipped galvanized welded wire mesh, then Anping Guangtong Hardware Wire Mesh Co., Ltd. is a great place to start. They offer a wide range of welded wire mesh products, including 1mm wire mesh, which is ideal for many different applications. So if you're in the market for some welded wire mesh, be sure to check them out!

Global Analysis of Woven Cloth For Copper Market 2020: Market Size by Types, Applications, Regions, and Manufacturers Revealed - a2z Press Release

Woven Copper Cloth: A Versatile Material for Various ApplicationsCopper has been used for centuries due to its excellent electrical conductivity, heat resistance, and corrosion resistance. It finds applications in various industries, ranging from electronics and electricals to automotive, aerospace, and construction. To enhance the properties of copper and make it suitable for diverse applications, woven copper cloth has emerged as a versatile material. In this blog post, we will explore the global market for woven copper cloth, its types, applications, and key manufacturers.Woven copper cloth, as the name suggests, is a fabric created by interweaving copper wires. This process produces a durable and flexible cloth that exhibits exceptional electrical conductivity, electromagnetic shielding, and thermal conductivity properties. The interlocking structure of the woven cloth ensures its strength and integrity, making it suitable for a range of industrial applications.One of the key applications of woven copper cloth is in the electronics and electricals industry. It is widely used as a grounding material in electronic circuitry, providing a low-resistance pathway for the flow of electric current. Its ability to effectively shield electromagnetic radiation makes it an ideal material for creating Faraday cages and shielding enclosures that protect sensitive electrical equipment from interference.The automotive industry also benefits from the use of woven copper cloth. It is employed in various car components, including gaskets, seals, and automotive wiring harnesses, where its high electrical conductivity helps in maintaining efficient electrical connections and preventing signal loss. Moreover, its corrosion-resistant properties make woven copper cloth an excellent choice for automotive applications, ensuring longevity and reliability.In the aerospace sector, woven copper cloth finds applications in the construction of aircraft parts and components. Its lightweight yet robust nature makes it an ideal material for manufacturing lightweight yet durable aircraft structures. Additionally, woven copper cloth's thermal conductivity properties enable effective heat dissipation in aerospace equipment, preventing overheating and enhancing overall performance.The construction industry also recognizes the benefits of woven copper cloth. It is utilized in various architectural applications, such as roofing, façades, and decorative elements. Woven copper cloth's natural patina gives it an aesthetically pleasing appearance, making it a popular choice for architectural designs. Furthermore, its antimicrobial properties make it a suitable material for healthcare facilities and other environments where cleanliness and hygiene are vital.The global market for woven copper cloth is witnessing significant growth due to the increasing demand for copper-based products across industries. Several key manufacturers contribute to this market, including (remove brand names). These companies focus on producing high-quality woven copper cloth to meet the diverse needs of their customers.In conclusion, woven copper cloth has emerged as a versatile material with numerous applications in various industries. With its exceptional electrical conductivity, electromagnetic shielding, and thermal conductivity properties, it provides an excellent solution for enhancing the performance and durability of various products. The global market for woven copper cloth is expanding rapidly, driven by increasing demand and technological advancements. As industries continue to innovate, woven copper cloth will play a crucial role in shaping a sustainable and advanced future.

Understanding the Application and Benefits of 5 Micron Filters: An Insightful Article by Brian Farno

Innovative Filtering Solutions Offer Enhanced Performance for Various Industries[City], [Date] - As industries continue to evolve and demand higher efficiency standards, companies are constantly seeking cutting-edge solutions to meet their filtration needs. One such company, specializing in filter elements, has introduced a ground-breaking product designed to address the diverse challenges faced by various industries. This novel solution, with a filtration level as low as 5 microns, ensures optimal performance and surpasses traditional filtering methods in terms of efficiency and reliability.With an extensive research and development process, the filter element industry has made significant strides in revolutionizing filtration technology. By reducing the filtration level to as low as 5 microns, manufacturers have crafted a product that offers unparalleled precision in its performance. The new filter element can effectively remove contaminants and impurities that were previously difficult to eliminate, thereby enhancing the overall quality of the output.One of the industries that stands to benefit greatly from this breakthrough is the automotive sector. Engines, especially those in high-performance vehicles, require meticulous filtration to maintain optimum performance. A 5-micron filter element provides a higher level of protection, preventing fine particles and impediments from clogging engines and reducing their efficiency. This newly introduced technology ensures enhanced engine performance and extends the lifespan of critical components, resulting in greater customer satisfaction and cost savings.The refining and chemical industries also rely heavily on efficient filtration systems to maintain product integrity and prevent equipment damage. Traditional filtration methods often fall short in capturing contaminants smaller than 5 microns, leading to compromised product quality and equipment issues. However, the introduction of an advanced 5-micron filter element mitigates these concerns by reliably removing these minute impurities, safeguarding both the product quality and the long-term health of the equipment.Another sector that greatly benefits from this cutting-edge technology is the pharmaceutical industry, where maintaining purity is of paramount importance. As pharmaceutical manufacturing processes require stringent quality control measures, employing a 5-micron filtration system guarantees the removal of even the smallest particulates, bacteria, and other impurities. This ensures the delivery of safe and effective medications, meeting the stringent regulatory requirements set forth by global health authorities.In addition to the direct advantages provided by this exceptional filtration system, its innovative features also yield long-term benefits. The enhanced efficiency of the 5-micron filter element translates to reduced maintenance costs and downtime for businesses. By effectively filtering out particles and contaminants, companies can prevent costly equipment malfunctions and breakdowns, thereby increasing productivity and profitability.To accommodate diverse industry needs, the 5-micron filter element is available in various configurations, including standard cartridges and high-capacity systems. This adaptability ensures compatibility across a wide range of applications and makes it easier for industries to seamlessly integrate the new technology into their existing operations.As the demand for enhanced performance and reliability continues to grow across industries, the introduction of the 5-micron filter element represents a significant advancement in filtration technology. By effectively removing contaminants down to this microscopic level, businesses can now achieve improved outcomes, greater product integrity, increased durability, and reduced maintenance costs. This innovative filtration solution is set to revolutionize the industry and pave the way for a more efficient and sustainable future.

Wire Mesh Stainless Steel: A Reliable Solution for Your Distribution Needs

[Company Name] Introduces Innovative Applications of Wire Mesh Stainless Steel[Place], [Date] - [Company Name], a renowned leader in the wire mesh industry, has recently unveiled their latest line of innovative applications for stainless steel wire mesh. Known for their commitment to quality, reliability, and superior customer service, [Company Name] has established itself as a trusted name in the industry.With years of experience and expertise in wire mesh manufacturing, [Company Name] has been at the forefront of developing cutting-edge solutions for a wide range of industries. Their advanced wire mesh products are widely used in automotive, aerospace, construction, filtration, and many other applications.Stainless steel wire mesh is known for its exceptional strength, durability, and resistance to corrosion. These qualities make it an ideal material for various applications where reliability and performance are of paramount importance. [Company Name] has further enhanced the properties of stainless steel wire mesh through their research and development efforts, resulting in innovative applications that push the boundaries of its potential.One of the primary areas where [Company Name] has made significant advancements is in the field of filtration. The company's wire mesh filters offer superior performance in various industries, including oil and gas, pharmaceuticals, food and beverage, and water treatment. These filters effectively remove impurities and contaminants, ensuring a clean and safe output.In the automotive and aerospace sectors, [Company Name] has designed specialized wire mesh products that provide high-strength reinforcement for composite materials. These composites are used to reduce weight while maintaining structural integrity, resulting in fuel efficiency and improved performance.Additionally, [Company Name] has expanded its product portfolio to cater to the growing demand for architectural wire mesh. Architects and designers can now utilize the company's aesthetically pleasing and durable stainless steel mesh for applications such as facades, interior partitioning, sunscreens, and decorative elements. The versatility of stainless steel wire mesh allows for endless creativity and customization to achieve stunning visual effects.To ensure the highest levels of quality, [Company Name] utilizes state-of-the-art manufacturing techniques and machinery. Their skilled technicians meticulously inspect each product to guarantee compliance with industry standards and customer specifications. Moreover, the company maintains a comprehensive quality control system, which includes regular testing and certification."By focusing on continuous innovation and customer satisfaction, we have been able to establish ourselves as a market leader in the wire mesh industry," said [Company Representative], CEO of [Company Name]. "We are committed to providing our customers with the best solutions for their specific needs, and our latest lineup of wire mesh stainless steel applications reflects that dedication."As a testament to their commitment to environmental sustainability, [Company Name] also adheres to eco-friendly manufacturing practices. The company ensures responsible waste management and minimizes its carbon footprint by investing in energy-efficient technologies.With their unrivaled expertise and diverse product range, [Company Name] is poised to take the wire mesh industry to new heights. By consistently delivering high-quality solutions, the company has earned the trust and loyalty of customers worldwide.For more information about [Company Name] and their innovative applications of wire mesh stainless steel, please visit their website [Website URL] or contact their sales team at [Contact Number].

Unlocking the Potential of Metal Wire Cloth: A Comprehensive Guide

Metal Wire Cloth: A Company Committed to Providing High-Quality and Efficient Filtering SolutionsMetal Wire Cloth is a top-quality manufacturer of wire mesh products and solutions that has been serving various industries worldwide for over two decades. The company offers custom-made wire mesh and filtration solutions that meet a wide range of applications, from simple to complex.Headquartered in China, Metal Wire Cloth has a well-equipped manufacturing unit backed by a team of highly skilled professionals. Their production facilities are equipped with advanced machinery and operate under strict quality control standards to ensure that every product is of high quality.The company's portfolio comprises a wide range of wire mesh products, including stainless steel wire mesh, brass wire mesh, and copper wire mesh, among others. These materials are popular for their durability, corrosion resistance, and high tensile strength properties. Metal Wire Cloth's wire mesh is available in different shapes and sizes, making it easy to customize to meet specific application requirements.Their filtering solutions include filter discs, sintered filters, and filter elements for applications in the automotive, chemical, food, and beverage, and pharmaceutical industries, among others. The filter discs are made from high-quality stainless steel wire mesh and are available in various micron ratings for efficient particle filtration. The filter elements are designed to provide high filtration efficiency, low-pressure drop, and long service life. Metal Wire Cloth's filtering solutions are highly efficient and reliable, making them ideal for use in demanding filtration applications.The company's mission is to provide efficient and reliable filtration solutions that help customers meet their unique filtration needs. They achieve this goal by continuously investing in research and development to improve product quality and innovation. The company's skilled engineers and technicians work with customers to understand their specific requirements to provide customized filtering solutions that meet their unique needs.Metal Wire Cloth prides itself on its commitment to quality and customer satisfaction. They strive to ensure that every product they produce meets or exceeds customer requirements and quality standards. The company's quality control processes are designed to test products at every stage of production, from raw materials to finished products, to ensure that they meet or exceed customer specifications.In addition to their commitment to quality, Metal Wire Cloth is also dedicated to maintaining environmentally friendly manufacturing practices. The company's production facilities comply with environmental regulations and are equipped with modern technologies that reduce emissions and minimize waste.The company has established a wide distribution network that enables them to serve customers in various parts of the world. They have developed a reputation as a reliable and trustworthy supplier of high-quality wire mesh products and filtering solutions. Their customers appreciate the company's commitment to quality, innovation, and customer satisfaction.In conclusion, Metal Wire Cloth is a leading manufacturer of wire mesh products and filtration solutions that have earned a reputation for quality, efficiency, and reliability. Their commitment to providing tailored solutions to meet unique customer needs has made them an ideal partner for companies looking for reliable filtering solutions. The company's focus on quality, innovation, and customer satisfaction is evident in everything they do, making Metal Wire Cloth a brand that customers can trust.

Stylish Copper Kitchen Cabinet Hardware Pulls with Hammered Texture

Hammered Kitchen Pulls, Copper Hardware Cloth, Satin Copper Kitchen Hardware Pulls, Copper Kitchen Cabinet Hardware PullsWhen it comes to designing and upgrading your kitchen, the smallest details can often make the biggest impact. One such detail that can instantly elevate the aesthetic of your kitchen is the choice of hardware pulls. And if you're looking for something unique and stylish, copper hardware pulls might just be the perfect option for you.Copper hardware pulls have been gaining popularity in recent years, and it's easy to see why. With their warm and rich color, they add a touch of elegance and sophistication to any kitchen. Whether you have a traditional or modern kitchen, copper pulls can seamlessly blend in and complement your existing decor.One type of copper hardware pull that stands out is the hammered kitchen pull. With its textured surface, it adds a rustic and handcrafted feel to your cabinets or drawers. The hammered finish gives it a unique and one-of-a-kind look that can't be replicated with other materials. If you're aiming for a farmhouse or industrial style kitchen, hammered copper pulls are the perfect choice.Besides the aesthetic appeal, copper hardware pulls also offer practical benefits. Copper is known for its antimicrobial properties, which means it naturally inhibits the growth of bacteria and other harmful microorganisms. In a kitchen where hygiene is crucial, copper pulls can help keep your space clean and safe.When choosing copper hardware pulls for your kitchen, there are different finishes to consider. Satin copper pulls have a smooth and brushed appearance, offering a more contemporary and refined look. They work well in modern kitchens and can add a touch of luxury to your space. On the other hand, if you prefer a more vintage or antique feel, you can opt for polished copper pulls. The shiny and reflective surface adds a nostalgic charm to your cabinets and drawers.Copper hardware pulls are versatile and can be paired with various cabinet and drawer styles. They can effortlessly complement white cabinets, creating a stunning contrast and adding warmth to the overall design. Whether you have a sleek and minimalist kitchen or a traditional and cozy one, copper pulls can enhance the overall aesthetic and tie the whole look together.If you're concerned about the durability of copper pulls, rest assured that they are built to last. Copper is a sturdy and resilient material that can withstand everyday wear and tear. Over time, it develops a beautiful patina that only adds to its charm and character. However, if you prefer to maintain the shiny appearance, regular polishing can easily restore its original luster.In conclusion, copper hardware pulls, particularly hammered kitchen pulls, are an excellent choice for adding style and elegance to your kitchen. The unique texture and warm color of copper can instantly enhance the aesthetic of your cabinets and drawers. Whether you prefer a contemporary or vintage look, copper pulls come in different finishes to suit your personal style. Not only are they visually appealing, but copper pulls also offer practical benefits with their antimicrobial properties. So, if you're looking to make a statement in your kitchen, consider investing in copper hardware pulls for a touch of timeless beauty.

Woven Wire Cloth Filters: Cylinder and Disc Filters - Made in China

article about the uses and benefits of filter cylinders and discs made from woven wire cloth.Filter cylinders and discs made from woven wire cloth are used extensively in a variety of industries and applications. They are essential components in processes that require the separation of solids from liquids or gases, and they offer numerous benefits that make them the ideal filter media for many different applications.Woven wire cloth is a durable and versatile material that can be used in a variety of filtration applications. It is made from high-quality stainless steel wire that is woven into a mesh pattern, which can then be shaped into a variety of different filter configurations. The resulting filter media offers high strength and durability, excellent filtration efficiency, and resistance to corrosion and abrasion.Filter cylinders and discs made from woven wire cloth are commonly used in the following applications:1. Chemical processing: Woven wire cloth filters are used to remove impurities from process streams in the chemical industry. They can be used in a wide range of applications, including the filtration of acids, alkalis, solvents, and other chemicals.2. Water treatment: Woven wire cloth filters are widely used in water treatment applications to remove dirt, sediment, and other contaminants from the water. They can be used in a variety of different filtration systems, including sand filters, cartridge filters, and multi-media filters.3. Food and beverage processing: Woven wire cloth filters are used to remove impurities from food and beverage products during the production process. They are commonly used in applications such as beer, wine, and dairy processing.4. Oil and gas: Woven wire cloth filters are used in the oil and gas industry to remove impurities from the crude oil and natural gas streams. They can be used in a variety of different applications, including the filtration of produced water, condensates, and other process streams.The benefits of using filter cylinders and discs made from woven wire cloth include:1. High filtration efficiency: Woven wire cloth filters offer excellent filtration efficiency, meaning that they can remove even very small particles from liquids or gases.2. Durability: Woven wire cloth filters are very durable and can withstand high temperatures, pressure, and other harsh conditions. They are resistant to corrosion and abrasion, which means that they can last for a long time without needing to be replaced.3. Customizability: Woven wire cloth filters can be customized to meet the specific needs of different applications. They can be shaped into a variety of different configurations, including discs, cylinders, and cones, and can be made to fit specific dimensions.4. Cost-effectiveness: Woven wire cloth filters are often more cost-effective than other types of filters. They are durable, long-lasting, and require very little maintenance, which means that they can save money on replacement costs and downtime.In conclusion, filter cylinders and discs made from woven wire cloth are essential components in many different applications. They offer high filtration efficiency, durability, customizability, and cost-effectiveness, making them the ideal filter media for a wide range of industries and processes. With their many benefits and uses, it is easy to see why woven wire cloth filters are such an important part of modern industry and manufacturing.

Efficient and Versatile Wire Mesh Disc Filters for Various Shapes and Sizes

release:Wire Mesh Discs Introduces Revolutionary Disc Filters with DXR TechnologyWire Mesh Discs, a leading provider of wire mesh solutions, has introduced a new line of disc filters with DXR technology, offering superior filtration capabilities to its clients. The new DXR filters feature a unique metal wire mesh design that provides high levels of filtration efficiency, durability, and flexibility, making them ideal for a wide range of industrial applications.The DXR disc filters are available in a range of shapes, including square, ellipse, rectangle, and circle with a hole. The filters are made of high-quality metal wire mesh, which can be customized to meet specific filtration needs. The DXR technology improves on the company's existing wire mesh disc filters, providing enhanced filtration performance, longer lifespan, and improved resistance.According to Wire Mesh Discs, the new DXR disc filters have been designed to provide high levels of filtration efficiency, removing particles as small as 2 microns. The unique metal wire mesh design also ensures that the filters are highly durable and resistant to corrosion and wear, ensuring that they can withstand harsh environments and provide reliable filtration performance for extended periods."Our new DXR disc filters offer a game-changing solution for clients looking for reliable, high-performance filtration products," said a spokesperson for Wire Mesh Discs. "We're thrilled to be able to offer our clients a product that is not only more advanced than anything else on the market but is also customizable to their specific filtration needs."The company's new disc filters with DXR technology are suitable for use in a wide range of industries, including pharmaceuticals, chemical processing, food and beverage production, oil and gas, water treatment, and more. Wire Mesh Discs has worked closely with its clients to customize filter solutions that meet their unique filtration requirements, ensuring that they can achieve optimal filtration performance while maximizing process efficiency and reducing operating costs.In addition to the new disc filters with DXR technology, Wire Mesh Discs offers a range of other wire mesh solutions, including woven wire mesh, welded wire mesh, expanded metal, perforated metal, and more. The company's solutions are widely used in industrial applications such as filtration, separation, protection, ventilation, and decoration.As one of the leading wire mesh solutions providers, Wire Mesh Discs is committed to delivering high-quality products and exceptional customer service to clients around the world. The company's team of experts offers technical support to help clients with their wire mesh needs, providing solutions that are customized, reliable, and cost-effective."We take pride in delivering wire mesh solutions that meet our clients' diverse needs," said the spokesperson. "Our team is committed to providing exceptional customer service at every step of the way, from product customization to post-sales support."Wire Mesh Discs' new disc filters with DXR technology are expected to be a popular choice among clients looking for high-performance filtration solutions that can withstand harsh industrial environments. With its commitment to innovation, quality, and service excellence, Wire Mesh Discs is poised to continue leading the wire mesh industry for years to come.

Discover the Latest in Stainless Steel Welded Wire Mesh in China

China Stainless Steel Welded Wire Mesh Industry Grows Amid Increasing DemandChina Stainless Steel Welded Wire Mesh, produced by numerous manufacturers across the country, has been witnessing significant growth due to the rising demand for high-quality wire mesh products in various sectors. This has resulted in the expansion of the industry as well as an increase in exports to meet international market needs.Stainless steel welded wire mesh is extensively used in construction, agriculture, filtration, mining, and other industries due to its durability, corrosion resistance, and versatility. The mesh is formed by welding stainless steel wires together in a lattice pattern, creating a strong and flexible material that can be customized according to specific requirements. Its wide range of applications, superior quality, and competitive prices have made it a popular choice among domestic and international buyers.One of the key players in the industry is a leading Chinese manufacturer known for its state-of-the-art production facilities and adherence to strict quality standards. Their stainless steel welded wire mesh is manufactured using advanced technologies and equipment, ensuring consistent quality and reliability. The company prides itself on its commitment to customer satisfaction and has gained a strong reputation both at home and abroad.With the rapid urbanization and infrastructure development in China, the construction industry has been the largest consumer of stainless steel welded wire mesh. It is commonly used for reinforcing concrete structures, preventing cracks and enhancing the overall strength and durability of buildings. The increasing demand for residential and commercial buildings has resulted in a surge in the production and sale of wire mesh products.Furthermore, the agricultural sector has also been driving the demand for stainless steel welded wire mesh. It is widely used for fencing, animal enclosures, and protecting crops from pests. The mesh's resistance to corrosion and harsh weather conditions makes it an ideal choice for outdoor applications in agriculture.The mining industry has also witnessed a significant increase in the use of stainless steel welded wire mesh. It is employed for various purposes such as screening, filtering, and safety barriers. The mesh's high tensile strength and resistance to corrosion make it well-suited for the challenging conditions encountered in mining operations.The filtration industry, which includes water treatment, oil and gas, and chemical processing, relies heavily on stainless steel welded wire mesh for effective separation and filtration processes. The mesh's precise openings and uniform structure enable the filtration of particles of different sizes, making it an indispensable component in these industries.In recent years, the Chinese stainless steel welded wire mesh industry has experienced a surge in exports, catering to the growing global demand. The products are exported to various countries across Asia, Africa, Europe, and the Americas. The industry has gained a strong foothold in the international market due to its competitive pricing, superior quality, and efficient supply chain management.However, the industry faces challenges such as increasing raw material costs and competition from other countries. Rising prices of stainless steel and fluctuating exchange rates have put pressure on manufacturers to maintain their competitive edge. To overcome these challenges, companies are adopting cost-effective production techniques and focusing on product innovation and development.In conclusion, China Stainless Steel Welded Wire Mesh industry is thriving due to the growing demand across various sectors such as construction, agriculture, filtration, and mining. The industry has been successful in meeting domestic and international market requirements, offering high-quality and competitively priced wire mesh products. As the industry continues to expand, manufacturers are embracing technological advancements and developing innovative solutions to sustain their growth.