Discover the Latest Developments in Wire Mesh Technology

By:Admin

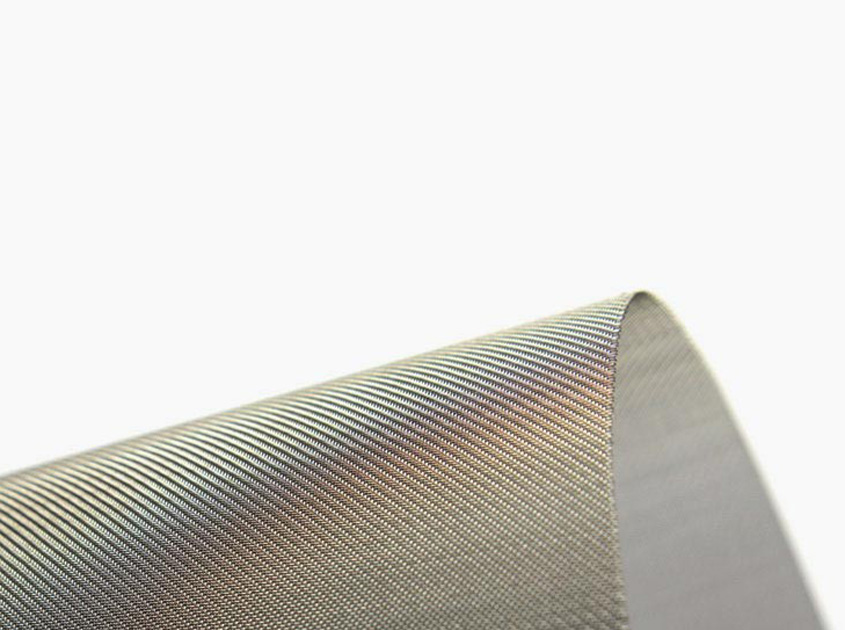

Ss Wire Mesh is known for their wide range of products, including stainless steel wire mesh, welded wire mesh, and wire mesh filters. Their products are used in various industries such as agriculture, construction, and industrial applications. The company takes pride in their ability to provide customized solutions to meet the needs of different clients.

One of the key factors that set Ss Wire Mesh apart from the competition is their state-of-the-art manufacturing facility. The company has invested heavily in modern equipment and technology to ensure that they can produce high-quality wire mesh products at a competitive price. This allows them to meet the demands of their customers while maintaining the highest standards of production.

In addition to their manufacturing capabilities, Ss Wire Mesh also prides itself on its commitment to sustainability. The company has implemented eco-friendly practices throughout their operations, from sourcing raw materials to reducing waste and energy consumption. This commitment to sustainability has not only helped the company reduce its environmental impact but has also positioned them as a leader in the industry.

The company's dedication to quality and customer satisfaction has earned them a strong reputation in the market. They have built long-term partnerships with many clients who trust them to deliver reliable and durable wire mesh products. Whether it's a small-scale project or a large industrial application, Ss Wire Mesh has the expertise and resources to meet the needs of their customers.

In a recent interview, the company's CEO expressed their commitment to continuous improvement and innovation. They stated that they are constantly investing in research and development to stay ahead of the curve in the industry. This commitment to innovation has allowed the company to expand their product line and offer cutting-edge solutions to their customers.

One of the recent innovations from the company is their new line of corrosion-resistant wire mesh products. These products are designed to withstand harsh environments and corrosive materials, making them ideal for applications in marine, chemical, and oil and gas industries. This new product line has generated a lot of excitement in the market and is expected to further enhance the company's position as a leader in the industry.

In addition to their product innovations, Ss Wire Mesh is also focused on expanding their market reach. The company has been exploring new markets and forging partnerships with distributors and suppliers worldwide. This strategic approach has helped them reach new customers and expand their global footprint.

Looking ahead, Ss Wire Mesh is poised for growth and success. With a strong foundation built on quality, innovation, and sustainability, the company is well-positioned to meet the evolving needs of their customers and the industry. Their commitment to excellence and their drive for continuous improvement make them a formidable force in the wire mesh manufacturing sector.

Company News & Blog

How to Choose the Right Fluid for Your Filter Element

article.In today's fast-paced and technologically advanced world, it is essential for companies to stay on top of their game and optimize their operations to stay competitive. One critical aspect of this optimization process is ensuring that equipment is functioning efficiently at all times, especially when it comes to fluid filtration.That's where Filter Element Fluid, a leading company in filtration solutions, comes in. With over 20 years of experience in the industry, Filter Element Fluid has cemented its reputation as a reliable and innovative brand.The company offers a wide range of filtration products, with a focus on hydraulic and lubrication filtration. One of its most popular products is the filter element, which is designed to remove contaminants from hydraulic and lubrication fluids, ensuring equipment remains functional and efficient.One of the unique features of Filter Element Fluid's filter elements is the advanced pleating technology used in their production. This technology ensures that the filter media has more surface area for filtration, allowing it to capture even the smallest particles for a more thorough filtration process.Moreover, Filter Element Fluid's filter elements are made from high-quality materials, ensuring they are durable and long-lasting. This means less downtime for equipment and fewer replacement costs for businesses.Another unique feature of Filter Element Fluid is its focus on customization. The company understands that each customer has specific needs and requirements when it comes to filtration, and as such, it offers customization options for its products.Customers can choose from a range of filter media, micron ratings, and sizes to fit their specific needs, ensuring they get a product that is designed to perform optimally for their equipment.In addition to its filtration products, Filter Element Fluid also provides value-added services such as oil analysis and consulting. These services help customers identify potential contamination sources and prevent equipment failure, saving them time and money in the long run.At Filter Element Fluid, the team is committed to providing exceptional customer service and support. Whether it's offering expert advice on which product to choose or providing fast and efficient delivery, the company is dedicated to customer satisfaction.In a world where machine downtime can be costly and disruptive, Filter Element Fluid's filtration solutions are a game-changer for businesses. With its advanced pleating technology, high-quality materials, and focus on customization and customer service, the company is poised for continued success and growth.

Discover the Latest Developments in Wire Mesh Technology

Ss Wire Mesh, a leading manufacturer of wire mesh products, has recently made headlines with their innovative approach to the industry. The company has been in the business for over 20 years, and their commitment to quality and customer satisfaction has set them apart from their competitors.Ss Wire Mesh is known for their wide range of products, including stainless steel wire mesh, welded wire mesh, and wire mesh filters. Their products are used in various industries such as agriculture, construction, and industrial applications. The company takes pride in their ability to provide customized solutions to meet the needs of different clients.One of the key factors that set Ss Wire Mesh apart from the competition is their state-of-the-art manufacturing facility. The company has invested heavily in modern equipment and technology to ensure that they can produce high-quality wire mesh products at a competitive price. This allows them to meet the demands of their customers while maintaining the highest standards of production.In addition to their manufacturing capabilities, Ss Wire Mesh also prides itself on its commitment to sustainability. The company has implemented eco-friendly practices throughout their operations, from sourcing raw materials to reducing waste and energy consumption. This commitment to sustainability has not only helped the company reduce its environmental impact but has also positioned them as a leader in the industry.The company's dedication to quality and customer satisfaction has earned them a strong reputation in the market. They have built long-term partnerships with many clients who trust them to deliver reliable and durable wire mesh products. Whether it's a small-scale project or a large industrial application, Ss Wire Mesh has the expertise and resources to meet the needs of their customers.In a recent interview, the company's CEO expressed their commitment to continuous improvement and innovation. They stated that they are constantly investing in research and development to stay ahead of the curve in the industry. This commitment to innovation has allowed the company to expand their product line and offer cutting-edge solutions to their customers.One of the recent innovations from the company is their new line of corrosion-resistant wire mesh products. These products are designed to withstand harsh environments and corrosive materials, making them ideal for applications in marine, chemical, and oil and gas industries. This new product line has generated a lot of excitement in the market and is expected to further enhance the company's position as a leader in the industry.In addition to their product innovations, Ss Wire Mesh is also focused on expanding their market reach. The company has been exploring new markets and forging partnerships with distributors and suppliers worldwide. This strategic approach has helped them reach new customers and expand their global footprint.Looking ahead, Ss Wire Mesh is poised for growth and success. With a strong foundation built on quality, innovation, and sustainability, the company is well-positioned to meet the evolving needs of their customers and the industry. Their commitment to excellence and their drive for continuous improvement make them a formidable force in the wire mesh manufacturing sector.

Discover the Versatile Applications of Wire Mesh in Various Industries

Nickel Wire Mesh: A Versatile Solution for Various IndustriesNickel wire mesh is a unique and versatile material that has found applications across numerous industries. With its exceptional corrosion resistance, high temperature resistance, and excellent electrical conductivity, nickel wire mesh has become an essential component in various processes and technologies.Nickel wire mesh is primarily made from pure nickel wires, carefully woven together to create a durable and flexible mesh structure. The combination of nickel's inherent properties and the mesh design provides a host of benefits that have made it indispensable in a wide range of applications.One notable characteristic of nickel wire mesh is its outstanding corrosion resistance. Thanks to the inherent properties of nickel, this mesh can withstand harsh environments, making it suitable for industries such as chemical processing, petrochemicals, and marine applications. The corrosion resistance of nickel wire mesh ensures the longevity and reliability of equipment, minimizing maintenance costs and downtime.In addition to its corrosion resistance, nickel wire mesh also boasts high temperature resistance, which makes it ideal for applications involving extreme heat. Industries such as aerospace, automotive, and power generation rely on this mesh to effectively filter gases or hot liquids, ensuring the safe and efficient operation of their systems. Nickel wire mesh's capacity to endure high temperatures without losing its structural integrity or performance contributes to increased productivity and overall safety.Moreover, nickel wire mesh exhibits outstanding electrical conductivity. This property makes it an excellent option for industries that require efficient electrical transmission. The mesh is commonly used in electronic devices, telecommunications equipment, and electrical circuits. Its high electrical conductivity ensures reliable and uninterrupted signal transmission, contributing to the smooth operation of various technologies.One industry that heavily relies on nickel wire mesh is the healthcare sector. In medical applications, such as surgical instruments and biomedical devices, this mesh is used for its biocompatibility and antimicrobial properties. Nickel wire mesh is often used as a material for filters, implants, and prosthetics due to its ability to resist chemical reactions with bodily fluids, ensuring patient safety and reducing the risk of infections.Another industry where nickel wire mesh plays a vital role is filtration. This mesh is widely used in liquid and gas filtration systems, where it effectively removes contaminants and impurities. The mesh's precisely woven structure enables efficient filtration, allowing for the purification of liquids in industries such as food and beverage, pharmaceuticals, and water treatment.Furthermore, nickel wire mesh finds extensive application in the automotive industry. It is used in exhaust systems, catalytic converters, and fuel cells due to its resistance to high temperatures and corrosion. The mesh helps to optimize performance, reduce emissions, and enhance the overall efficiency of automotive components.Overall, nickel wire mesh has become an indispensable material across multiple industries due to its exceptional properties. Its corrosion resistance, high temperature resistance, and electrical conductivity make it an ideal choice for various applications, ranging from chemical processing to healthcare. With its versatility and reliability, nickel wire mesh continues to pave the way for advancements in numerous industries, contributing to enhanced efficiency, reduced costs, and improved safety.

Quality Crimped Wire Mesh Manufacturers for Your Project

Crimped Wire Mesh Manufacturers are proud to announce their latest advancements in the production of high-quality wire mesh products. With a commitment to precision engineering and quality craftsmanship, they have established themselves as a leader in the industry.The company, with its extensive experience and expertise in wire mesh manufacturing, has been catering to a wide range of industries including construction, mining, agriculture, and petrochemical. They offer a diverse range of wire mesh products, including stainless steel crimped wire mesh, galvanized crimped wire mesh, and heavy duty crimped wire mesh. Their products are well-known for their durability, strength, and resistance to corrosion, making them ideal for demanding applications.The crimped wire mesh manufactured by the company is made from high-quality raw materials, ensuring superior performance and longevity. Their state-of-the-art manufacturing facilities are equipped with advanced machinery and technology, enabling them to produce wire mesh products that meet the highest industry standards.In addition to their standard product offering, Crimped Wire Mesh Manufacturers also provide custom wire mesh solutions to meet specific customer requirements. They work closely with their clients to understand their unique needs and provide tailored wire mesh solutions that perfectly fit their specifications. The company’s commitment to customer satisfaction and product quality has earned them a solid reputation in the industry.The company’s dedication to quality extends beyond their products to their customer service and support. They have a team of highly skilled and experienced professionals who are committed to providing exceptional service to their clients. Whether it’s technical assistance, product recommendations, or after-sales support, the team at Crimped Wire Mesh Manufacturers is always ready to assist their customers.One of the key factors that sets Crimped Wire Mesh Manufacturers apart from their competitors is their focus on innovation and continuous improvement. They are constantly investing in research and development to enhance their manufacturing processes and develop new and improved wire mesh products. This dedication to innovation has allowed them to stay ahead of the competition and cement their position as a leading wire mesh manufacturer.The company is also dedicated to sustainability and environmental responsibility. They adhere to strict environmental regulations and guidelines in their manufacturing processes, ensuring that their operations have minimal impact on the environment. Additionally, they are committed to reducing waste and maximizing resource efficiency throughout their production processes.Crimped Wire Mesh Manufacturers also prioritize workplace safety and employee well-being. They have implemented comprehensive safety protocols and policies to ensure a safe and healthy work environment for their staff. They also provide ongoing training and development opportunities to empower their employees and help them reach their full potential.As a testament to their commitment to quality and excellence, Crimped Wire Mesh Manufacturers have earned several certifications and accolades for their products and manufacturing processes. Their adherence to international quality standards and regulations has made them a trusted and reliable partner for companies across various industries.In conclusion, Crimped Wire Mesh Manufacturers’ dedication to quality, innovation, and customer satisfaction has positioned them as a leader in the wire mesh manufacturing industry. With a strong focus on product quality, customer service, and environmental responsibility, they continue to set the standard for excellence in the industry. Whether it’s standard wire mesh products or custom solutions, customers can trust Crimped Wire Mesh Manufacturers to deliver superior quality products and unmatched service.

Durable and Versatile Wire Mesh for Various Applications

Brass Wire Mesh is a versatile and highly durable material that is used in a wide range of applications. It is made from high quality brass wire and is woven into a sturdy and flexible mesh. This type of mesh is commonly used in filtration, separation, and reinforcement applications across various industries, including aerospace, automotive, agriculture, and construction.One of the leading manufacturers of Brass Wire Mesh is a well-established company that has been in operation for over [number] years. They have a state-of-the-art production facility that is equipped with advanced machinery and equipment to ensure the highest level of quality and precision in their brass wire mesh products.The company is known for its commitment to excellence and customer satisfaction. They take pride in their ability to deliver top-notch products that meet the specific requirements and standards of their clients. With a team of skilled and experienced professionals, they have the expertise to produce brass wire mesh in a wide range of specifications, including different mesh sizes, wire diameters, and weave patterns.In addition to their standard brass wire mesh products, the company also offers customization options to meet the unique needs of their customers. They work closely with their clients to understand their specific requirements and provide tailored solutions that align with their expectations. Whether it is for a small-scale project or a large industrial application, the company has the capability to deliver brass wire mesh that meets the highest quality standards.Furthermore, the company places a strong emphasis on research and development to stay ahead of industry trends and advancements. They continuously invest in technology and innovation to improve their manufacturing processes and develop new products that cater to evolving market demands. This dedication to continuous improvement has earned them a reputation as a reliable and innovative supplier of brass wire mesh in the industry.The brass wire mesh manufactured by the company is known for its exceptional strength, corrosion resistance, and durability. It can withstand extreme temperatures and environmental conditions, making it suitable for use in demanding industrial and commercial applications. Whether it is for filtration, sieving, shielding, or other specialized uses, the company’s brass wire mesh is designed to deliver reliable performance and longevity.Moreover, the company is committed to sustainability and environmental responsibility in their operations. They adhere to strict quality control measures to ensure that their production processes are efficient and eco-friendly. As a result, their brass wire mesh products are manufactured in a sustainable manner, with minimal impact on the environment.The company has also established a strong distribution network to serve their customers globally. They have a strong presence in international markets and work closely with distributors and partners to ensure timely delivery and support for their products. This global reach has enabled them to build long-standing relationships with clients in diverse industries and expand their market presence worldwide.Overall, the company’s dedication to quality, innovation, and customer satisfaction has positioned them as a leading manufacturer of brass wire mesh. Their commitment to excellence and their ability to deliver tailored solutions have set them apart in the industry. With a focus on continuous improvement and a customer-centric approach, they are poised to remain a trusted partner for brass wire mesh solutions for years to come.

Durable and Stylish Stainless Steel Wire Mesh for Various Applications

Black Stainless Steel Wire Mesh: The Ideal Solution for Industrial ApplicationsIn today's industrial applications, the demand for high-quality, durable materials is more crucial than ever. This is why the introduction of Black Stainless Steel Wire Mesh from [company] has been so widely embraced by industries around the world. This innovative product offers a range of benefits, making it the ideal solution for a variety of industrial needs.[Company] is a leader in the manufacturing and distribution of wire mesh products. With a long-standing reputation for excellence and innovation, the company has become a trusted name in the industry. Their commitment to quality, performance, and customer satisfaction has made them a top choice for businesses in a wide range of sectors, from construction and agriculture to aerospace and automotive.The Black Stainless Steel Wire Mesh from [company] is a testament to the company’s dedication to providing cutting-edge solutions to meet the evolving needs of their customers. This durable and versatile material offers a range of benefits that make it well-suited for a variety of industrial applications.One of the key advantages of Black Stainless Steel Wire Mesh is its exceptional strength and durability. Stainless steel is well-known for its resistance to corrosion, heat, and chemical damage, and the black coating adds an extra layer of protection. This makes the wire mesh an ideal choice for applications where it will be exposed to harsh conditions, such as in outdoor environments or industrial settings.In addition to its durability, Black Stainless Steel Wire Mesh also offers excellent stability and flexibility. This combination of strength and malleability makes it a versatile material that can be easily manipulated and shaped to suit a wide range of needs. Whether it’s used for filtration, screening, or reinforcement, this wire mesh can be customized to meet the specific requirements of any application.Furthermore, the black color of the wire mesh adds to its aesthetic appeal, making it a popular choice for architectural and decorative applications. The sleek and modern look of the black stainless steel adds a touch of sophistication to any project, making it a preferred option for designers and architects.At [company], customer satisfaction is a top priority, and the Black Stainless Steel Wire Mesh is no exception. The company offers a wide range of customization options, including different weave patterns, mesh sizes, and coating thicknesses, to ensure that each customer's specific needs are met. This commitment to providing tailored solutions has earned [company] a reputation for excellence in customer service and satisfaction.The applications for Black Stainless Steel Wire Mesh are nearly endless. From industrial filtration and separation to architectural and decorative features, this versatile material has proven to be an invaluable asset across a wide range of industries. Its durability, flexibility, and aesthetic appeal make it a top choice for businesses looking for high-quality, reliable materials that can withstand the rigors of industrial use.In conclusion, the introduction of Black Stainless Steel Wire Mesh from [company] has been a game-changer for industries looking for durable, high-performance materials. With its exceptional strength, versatility, and aesthetic appeal, this wire mesh is the ideal solution for a wide range of industrial applications. As [company] continues to lead the way in providing innovative materials and exceptional customer service, their Black Stainless Steel Wire Mesh is sure to remain a top choice for businesses around the world.

High-Pressure Filter Elements: Enhancing Filtering Efficiency

Title: Cutting-Edge High Pressure Filter Element Revolutionizes Filtration TechnologyIntroduction:In today's rapidly advancing industrial sector, businesses are constantly searching for innovative solutions to enhance operational efficiency, productivity, and environmental sustainability. Strengthening this quest further, an industry-leading company has recently unveiled its groundbreaking High Pressure Filter Element, poised to revolutionize the filtration technology landscape. By effectively removing contaminants from fluids under high-pressure circumstances, this cutting-edge filter element promises to deliver superior performance, exceptional quality, and unparalleled reliability across a wide range of industries.Main Body:1. The Need for Advanced Filtration Technology (100 words)In industries dealing with high-pressure fluid systems, such as oil and gas, automotive, manufacturing, and aerospace, the demand for robust and efficient filtration technology is paramount. Contaminants, such as particles, oil varnish, water, and other impurities, can greatly impact the performance and longevity of critical components. Hence, the introduction of the High Pressure Filter Element is a significant development, as it addresses these challenges with its advanced filtration capabilities.2. Unveiling the High Pressure Filter Element (150 words)Manufactured by a globally recognized company committed to technological advancements and customer satisfaction, the High Pressure Filter Element incorporates state-of-the-art design principles and cutting-edge materials. Its unique construction ensures exceptional strength, longevity, and unrivaled filtering performance, making it the ideal choice for high-pressure filtration applications. The innovative design consists of multiple layers of advanced filtration media that allow for efficient removal of contaminants without compromising fluid flow rates.3. Superior Performance and Efficiency (150 words)The High Pressure Filter Element has been extensively tested and validated to provide remarkable filtration efficiency, capable of removing particles as small as a few microns. This ensures that the filtered fluid meets or exceeds industry cleanliness specifications, safeguarding the integrity of vital equipment and reducing maintenance costs. The filter element's high dirt-holding capacity prolongs service intervals, resulting in improved operational uptime and reduced downtime. Moreover, its robust construction enables reliable operation even under extreme pressures and fluctuating conditions, ensuring consistent and high-quality filtration performance.4. Versatility and Customization Options (150 words)Recognizing the diverse needs of various industries, the High Pressure Filter Element offers a wide array of options and customization possibilities. Clients can choose from a range of filtration ratings, sizes, and configurations to match their specific requirements. With compatibility across multiple fluids, including hydraulic oils, lubricants, coolants, and process fluids, this versatile filter element caters to a broad range of applications. Additionally, advanced monitoring features such as pressure differential indicators and bypass valves can be incorporated to enhance the system's functionality and provide improved filter element change-out timelines.5. Environmental Sustainability and Cost Savings (150 words)Apart from its exceptional performance and versatility, the High Pressure Filter Element contributes significantly to environmental sustainability efforts. By effectively removing contaminants, it helps extend the service life of equipment, reducing the need for frequent component replacements, and minimizing waste generated from maintenance activities. As a result, businesses can experience substantial cost savings in terms of replacement parts, downtime, and disposal. Furthermore, the filter element's optimized design and advanced materials promote energy efficiency, ensuring that the filtration process consumes minimal power, which aligns with the company's commitment to reducing carbon footprints.Conclusion:The introduction of the High Pressure Filter Element heralds a new era in filtration technology, providing industries with a cutting-edge solution that delivers superior performance, exceptional quality, and unwavering reliability. This innovative filter element addresses the critical need for advanced filtration capabilities in high-pressure fluid systems, safeguarding equipment while reducing maintenance costs and environmental impact. With its versatility, customization options, and commitment to sustainability, this groundbreaking product promises to create a lasting impact on various industries, contributing to a more efficient, productive, and environmentally-conscious future.

Top Quality Stainless Steel Filter Wire Mesh Cloth Now Available for Purchase

Stainless Steel Filter Wire Mesh Cloth Factory Announces Expansion PlansStainless Steel Filter Wire Mesh Cloth Factory, a leading manufacturer of high-quality wire mesh products, has announced its plans for expansion. The company, which has been operating for several years, has earned a reputation for producing durable and reliable wire mesh products that have been helping customers across diverse industries meet their filtration needs. Through its expansion, the company aims to enhance its production capacity and meet the growing demand for its products.A spokesperson for the Stainless Steel Filter Wire Mesh Cloth Factory said, "We are pleased to announce our expansion plans during these uncertain times. Our decision to expand our production capabilities is driven by our commitment to meeting our customers' needs. We have been receiving increasing demand for our wire mesh products, and want to ensure that we have the capacity to cater to our customers' needs while maintaining the highest standards of quality."The company currently supplies its wire mesh products to a wide range of industries, including the automotive, aerospace, oil and gas, and food and beverage industries. Its products include woven wire mesh, perforated metal, welded wire mesh, and filter discs, among others. The company has invested heavily in research and development to ensure that its products are innovative, durable, and provide optimum performance.The spokesperson added, "We have a skilled workforce that is committed to delivering high-quality wire mesh products to our customers. Our expansion plans will also include additional hiring to meet the increasing demand for our products. We will also be upgrading our manufacturing processes to ensure that our customers receive the best possible products."The Stainless Steel Filter Wire Mesh Cloth Factory is committed to sustainability and environmental protection. It uses high-quality and eco-friendly materials and employs energy-efficient manufacturing processes. The company's products are also recyclable, which helps to reduce waste and conserve natural resources.The company's expansion plans will enable it to serve a wider range of customers from different industries. By increasing its production capacity, the company hopes to realize its goal of becoming a leading manufacturer of wire mesh products worldwide."Expanding our production capacity will enable us to offer better lead times and improve our overall customer service. We are excited about the future and the opportunity to grow our business and serve more customers," said the spokesperson.Apart from its production capabilities, the Stainless Steel Filter Wire Mesh Cloth Factory is also committed to providing exceptional customer service. It offers personalized support to its customers to ensure that they have the best possible experience when working with the company. Its knowledgeable team is always ready to answer any questions or concerns that customers may have.In conclusion, the expansion plans by Stainless Steel Filter Wire Mesh Cloth Factory reflect the company's commitment to meeting the needs of its customers. The company's reputation for quality, reliability, and innovation has seen it gain traction in diverse industries, and the expansion plans are a step towards maintaining its leading position in the industry. With its focus on sustainability, customer service, and innovation, it is likely that the company will continue to grow and expand its operations.

Get the Ultimate Deals on Air Filters – Shop Now for Unbeatable Savings! Enjoy Free Delivery and Returns on eBay Plus Items.

Title: Stainless Steel Filter Element: Unparalleled Air Filtration for a Cleaner EnvironmentIntroduction:Air pollution is a pressing concern worldwide, and the need for effective air filtration systems has never been greater. Filtering the air we breathe is crucial for maintaining good health and preventing various respiratory illnesses. One reliable solution to tackle air contamination is the stainless steel filter element. In this blog, we will explore the benefits and functionality of stainless steel filter elements, highlighting their importance within air filtration systems.Why Choose Stainless Steel Filter Elements?Stainless steel filter elements have gained immense popularity due to their exceptional durability, versatility, and unmatched filtering capabilities. Unlike traditional filters, which may degrade over time due to exposure to corrosive elements, stainless steel filters offer enhanced longevity. Let's delve deeper into the numerous benefits provided by these remarkable air filtration products.1. Unrivaled Durability:Stainless steel filter elements are designed to withstand extreme conditions, making them an ideal choice for various industrial applications. Their high tensile strength and corrosion resistance minimize the risk of breakage, providing a longer lifespan compared to other filter materials. This durability ensures consistent filtration performance, translating into cost savings over time.2. Superior Filtration Efficiency:The primary objective of any air filtration system is to remove harmful contaminants from the air. Stainless steel filter elements excel in this realm, thanks to their fine mesh structure and large surface area. The dense filter matrix and precision-engineered pores effectively capture particles as small as dust, pollen, bacteria, and even odors. By eliminating these unwanted impurities, stainless steel filter elements help maintain cleaner and healthier indoor environments.3. Easy to Maintain:Stainless steel filter elements are designed for hassle-free maintenance. Unlike disposable filters that require frequent replacement, these filters only need occasional cleaning. A simple rinse with water and mild detergent can remove accumulated dirt and debris, allowing the filter element to perform optimally once again. This not only saves time and effort but also helps reduce waste and promote sustainability.4. Versatile Applications:Stainless steel filter elements find widespread application across various industries, including automotive, chemical, pharmaceutical, food processing, and more. From atmospheric air filtration to process air purification, these filters ensure optimal air quality in diverse settings. Their versatility allows for customization, ensuring compatibility with different systems and equipment.5. Long-Term Cost Savings:Investing in a high-quality stainless steel filter element promises long-term cost savings. The durability and longevity of these filters eliminate the need for frequent replacements, reducing maintenance expenses. Additionally, the improved air quality and enhanced filtration efficiency contribute to improved equipment performance, reducing energy consumption and prolonging the lifespan of the entire system.Conclusion:As air pollution continues to pose a significant threat to our environment and health, it is crucial to invest in reliable air filtration solutions. Stainless steel filter elements offer unparalleled durability, superior filtration efficiency, and ease of maintenance, making them an exceptional choice. Their wide-ranging applications and long-term cost savings make them a wise investment for both commercial and residential settings.By incorporating a stainless steel filter element into your air filtration system, you can ensure cleaner and healthier air for you and your loved ones. Embrace this cutting-edge technology and make a positive impact on indoor air quality today.Remember, when it comes to air filters, stainless steel filter elements are the ultimate choice for effectiveness and longevity.Keywords: Stainless Steel Filter Element, air filtration, durability, filtration efficiency, maintenance, applications, cost savings.

Woven Metal Fabric Takes The Fashion Industry By Storm" rewritten as "Revolutionary Woven Metal Fabric Influencing Fashion Trends

Title: Innovative Woven Metal Fabric Revolutionizes Multiple IndustriesIntro: In a world that constantly seeks innovative materials to enhance various applications, the advent of woven metal fabric has opened up new possibilities across multiple industries. This groundbreaking technology, pioneered by a leading materials manufacturer and distributor, is poised to revolutionize sectors such as architecture, automotive, fashion, and more. With its exceptional properties and versatility, woven metal fabric is set to take center stage as a unique and game-changing solution.1. Introduction to Woven Metal Fabric As a high-tech material, woven metal fabric represents the fusion of technology and fashion, combining the strength and durability of metal with the flexibility and design possibilities of fabric. The intricate weaving process allows for the creation of metallic textiles that possess qualities including lightness, transparency, strength, and electrical conductivity. Its phenomenal strength-to-weight ratio makes it an ideal replacement for traditional materials when it comes to achieving structural integrity while minimizing the overall weight.2. Applications in Architecture and Construction The architectural industry has quickly recognized the revolutionary potential of woven metal fabric. Architects and designers can now integrate this material in their creations to bring a touch of elegance, strength, and uniqueness to their structures. Incorporating the metallic fabric into building facades, cladding systems, partitions, and curtains offers endless possibilities for aesthetic expression and functionality. Moreover, the inherent translucency of the fabric allows for creative lighting designs and visually stunning architectural effects.3. Automotive industry: Enhancing Performance and Design In the automotive realm, woven metal fabric is being hailed as a game-changer. With its lightweight yet robust nature, it presents the perfect solution for enhancing performance while maintaining fuel efficiency. Manufacturers are exploring the possibilities of incorporating the fabric into vehicle exteriors, interiors, and even components such as seating, to create visually striking and technologically advanced automobiles. Additionally, the fabric's electrical conductivity opens up avenues for the integration of electronic systems seamlessly into the vehicle's structure.4. Fashion and Wearable Technology: A Match Made in Heaven Woven metal fabric has found a natural partner in the world of fashion. Designers are capitalizing on its unique properties to create garments and accessories that are at once fashionable and functional. From haute couture runways to everyday wear, this metal-imbued fabric adds a touch of futuristic elegance to any outfit. Beyond aesthetics, the fabric's electrical conductivity has also led to innovative wearable technology applications, such as smart clothing and interactive accessories.5. Industrial and Safety Applications With its unparalleled strength and durability, woven metal fabric finds practical use in industrial settings. Its ability to withstand extreme temperatures, resist corrosion, and provide superior protection against projectiles positions it as an essential material in demanding applications such as safety clothing, aerospace, and shipbuilding. The fabric's inherent fire and heat resistance make it an ideal candidate for flame-retardant suits in high-risk environments, ensuring the safety of workers across various industries.6. A Lean and Environmentally Friendly Solution Woven metal fabric aligns perfectly with the growing emphasis on sustainability in manufacturing and construction. The material's low density and energy-efficient production process contribute to a reduced carbon footprint. By reducing the usage of traditional heavier materials, it offers greater fuel efficiency and consequently reduces emissions in transportation. Moreover, the durability and longevity of this fabric ensure a longer lifespan, reducing the need for frequent replacements and minimizing waste.Conclusion:The emergence of woven metal fabric has sparked excitement in numerous industries, enabling unique and innovative solutions that were once unimaginable. Its combination of strength, flexibility, electrical conductivity, and aesthetics has made it a preferred choice in architecture, automotive design, fashion, and industrial applications. As this groundbreaking technology continues to evolve, it is set to transform existing paradigms and propel the development of new and exciting products across various sectors.