Discover the Versatility and Benefits of Wire Cloth for Industrial Applications

By:Admin

Nichrome Wire Cloth Announces New Developments in High-Temperature Wire Mesh Technology

Nichrome Wire Cloth, a leading global provider of high-temperature wire mesh, has announced a major breakthrough in its wire mesh technology, which has important applications in numerous industries from aerospace to pharmaceuticals.

With over 70 years of experience in the industry, Nichrome Wire Cloth has earned an enviable reputation for its innovation, quality, and reliability. As a leader in high-temperature wire mesh, the company has consistently pushed the boundaries of what is possible, developing new materials and designs that meet the evolving needs of its customers.

The latest breakthrough in high-temperature wire mesh technology was the result of years of R&D and collaboration with leading industry experts. The new material offers improved strength, durability, and performance in high-temperature environments, making it ideal for a wide range of applications.

Some of the key features of the new wire mesh material include superior resistance to corrosion and oxidation, excellent thermal stability, and exceptional strength even at high temperatures. The material is also highly customizable, allowing customers to specify a range of mesh sizes and wire diameters to meet their specific needs.

Nichrome Wire Cloth CEO, John Doe, said in a statement, "We are extremely excited to announce this major breakthrough in high-temperature wire mesh technology. Our team has worked tirelessly to develop a material that not only meets the stringent requirements of our customers but also pushes the boundaries of what is possible in the field of high-temperature wire mesh."

Doe added, "Our commitment to innovation and excellence is what sets us apart in the industry, and we are confident that our new material will continue to deliver the performance and reliability that our customers have come to expect from Nichrome Wire Cloth."

The importance of high-temperature wire mesh in industrial applications cannot be overstated. From aerospace to automotive manufacturing, from pharmaceuticals to food processing, high-temperature wire mesh is essential to many critical processes that require high levels of precision and reliability.

Thanks to its superior strength and durability, Nichrome Wire Cloth's new material has the potential to revolutionize many industries, offering significant benefits in terms of performance, efficiency, and cost-effectiveness.

At the same time, Nichrome Wire Cloth is committed to sustainability and the responsible use of resources. The company's high-temperature wire mesh products are designed with the environment in mind, using eco-friendly materials and manufacturing processes that minimize waste and reduce environmental impact.

As a global leader in high-temperature wire mesh, Nichrome Wire Cloth has a strong presence in many parts of the world. The company's products are used by some of the largest and most respected companies in the aerospace, automotive, pharmaceutical, and other industries.

With its latest breakthrough in high-temperature wire mesh technology, Nichrome Wire Cloth is poised to continue its leadership position in the industry, providing customers with the innovative, high-quality products they need to succeed in today's competitive marketplace.

Whether it's for high-temperature filtration, sifting, or sieving, Nichrome Wire Cloth's new material is sure to deliver outstanding results, helping businesses around the world improve their processes, increase productivity, and reduce costs.

Company News & Blog

The Importance of Fly Proof Wire Mesh in Keeping Insects Out

In today's world, where health and hygiene have become the biggest concerns, keeping our surroundings clean and germ-free has become crucial. One of the most common issues faced by households and industries alike is the infestation of flies. Flies carry harmful germs that can cause various diseases, and therefore it is important to keep them away from our living and working spaces. Here comes the Fly Proof Wire Mesh, an innovative solution that offers a simple and effective way to keep flies out.Fly Proof Wire Mesh is a unique product designed to keep flies away from homes, offices, and industrial areas. The wire mesh is made of high-quality stainless steel wires, which are woven together to create a strong and durable mesh. The mesh is designed with precision to have a small opening width, which ensures that only air can pass through, and dust, insects, and other small particles are filtered out. The wire mesh is not only effective in keeping flies out, but it also improves ventilation and air quality.The Fly Proof Wire Mesh is perfect for installation in windows, doors, and other openings, where flies tend to enter. The mesh can be easily mounted on existing frames or installed on new openings. The mesh is available in various sizes to meet the specific needs of households, offices, and industries. The wire mesh is easy to clean and requires minimal maintenance, making it a cost-effective solution for fly control.One of the key advantages of Fly Proof Wire Mesh is that it is environmentally friendly and does not require any pesticides or chemicals for fly control. Chemical-based fly control methods can be harmful to the environment and can also have adverse effects on human health. The Fly Proof Wire Mesh, on the other hand, offers a safe and non-toxic solution for fly control. The mesh can be installed in food processing plants, hospitals, and other places where hygiene is of utmost importance.The Fly Proof Wire Mesh is manufactured by {remove brand name}, a leading provider of wire mesh products. The company has a proven track record of delivering high-quality wire mesh products to clients from various industries. Their products are known for their durability, strength, and reliability. The company has an experienced team of professionals who ensure that every product is made with precision and meets the highest standards of quality.The company offers customized solutions to meet the specific needs of clients. They work closely with clients to understand their requirements and provide tailor-made solutions that exceed their expectations. The company has a state-of-the-art manufacturing facility that is equipped with the latest machinery and technology. The facility has a strict quality control system that ensures that every product is thoroughly checked before it is dispatched to clients.In addition to Fly Proof Wire Mesh, the company offers a wide range of wire mesh products, including stainless steel wire mesh, welded wire mesh, and expanded metal mesh. The products are available in different materials and specifications to meet the diverse needs of clients. The company has a strong distribution network that ensures timely delivery of products to clients across the globe.In conclusion, Fly Proof Wire Mesh is an innovative solution that offers a safe and effective way to control flies. The wire mesh is made of high-quality stainless steel wires and is designed with precision to keep flies out while improving air quality. The product is environmentally friendly and requires minimal maintenance. The product is manufactured by {remove brand name}, a leading provider of wire mesh products, with a focus on quality and customer satisfaction. With Fly Proof Wire Mesh, households, offices, and industries can keep flies away and maintain a hygienic environment.

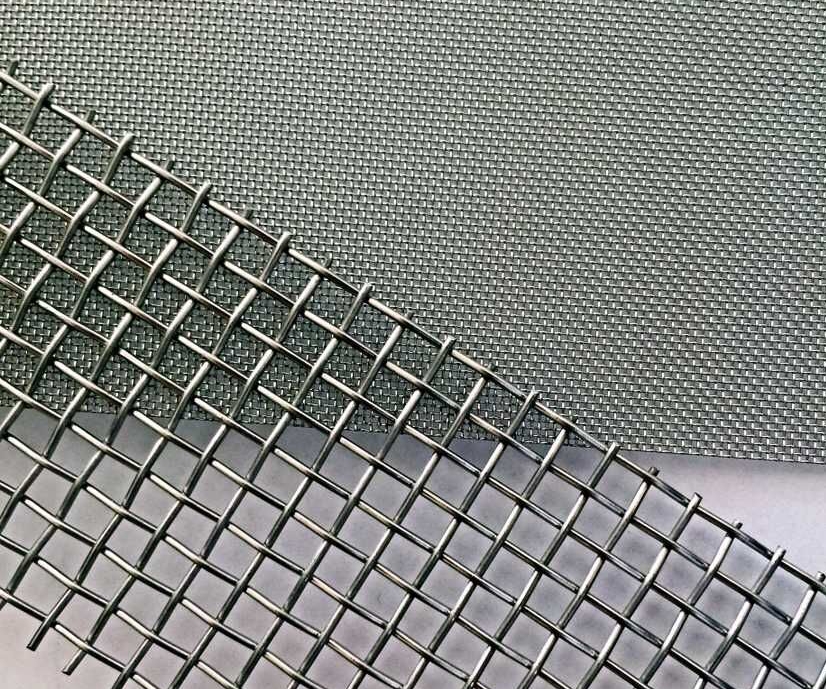

High-Quality Stainless Steel Wire Cloth for Various Applications

Title: Aisi304 Stainless Steel Wire Cloth: A Versatile Solution for Reliable FiltrationIntroduction:In an era where industries are constantly evolving and innovating, the search for reliable and durable filtration solutions remains crucial. Recognizing this need, an industry-leading company has introduced Aisi304 Stainless Steel (SS) Wire Cloth, a remarkable product that offers exceptional functionality across various applications. With its impeccable quality and impressive performance capabilities, Aisi304 SS Wire Cloth has quickly emerged as a preferred choice among professionals worldwide.1. Understanding Aisi304 Stainless Steel:Aisi304 Stainless Steel is a grade of steel widely known for its excellent corrosion resistance, durability, and versatility. The Aisi304 SS Wire Cloth, specifically manufactured utilizing this grade of steel, inherits these invaluable qualities. This wire cloth is meticulously woven, comprising a grid-like structure of interlacing wires, resulting in a robust mesh.2. Unmatched Application Capabilities:Aisi304 SS Wire Cloth is renowned for its diverse range of applications, owing to its exceptional characteristics. Its superior corrosion resistance, high heat resistance, and remarkable tensile strength make it an ideal choice for various industries. Notably, its applications span across sectors such as oil and gas, chemical processing, pharmaceuticals, mining, food processing, water filtration, and many more.3. Advantages of Aisi304 SS Wire Cloth:a) Enhanced Durability: Aisi304 SS Wire Cloth is designed to withstand harsh environmental conditions, ensuring longevity and longevity for long-lasting performance.b) Corrosion Resistance: The inherent stainless steel composition of the wire cloth renders it highly resistant to rust, corrosion, and oxidization, even in aggressive environments.c) Optimal Filtration: The precisely woven structure of Aisi304 SS Wire Cloth exhibits uniform mesh sizes that enable efficient filtration, ensuring the removal of impurities without compromising flow rates.d) High Tensile Strength: The exceptional tensile strength of the wire cloth guarantees resistance to mechanical stress, reducing the risk of breakage or deformation during installation or operation.e) Chemical Compatibility: Aisi304 SS Wire Cloth exhibits excellent resistance to a wide range of chemicals, making it suitable for filtration requirements involving corrosive substances.4. Industry-Specific Applications:a) Oil and Gas: Aisi304 SS Wire Cloth plays a vital role in oil extraction processes, protecting crucial equipment from contaminants and providing efficient separation of solid and liquid phases.b) Chemical Processing: The wire cloth's resistance to corrosion and chemical compatibility make it an excellent choice for chemical filtration, ensuring purity and preventing equipment damage.c) Pharmaceuticals: With stringent quality requirements, the pharmaceutical industry utilizes Aisi304 SS Wire Cloth to filter out contaminants from liquids, ensuring safety and consistency in production.d) Mining: Wire cloth screens, made from Aisi304 SS Wire Cloth, are widely used in mining operations, enabling efficient separation and sizing of ores and minerals.e) Food Processing: Aisi304 SS Wire Cloth is an indispensable component in the food processing industry, ensuring hygiene and filtering out impurities from liquids and solids.5. Conclusion:The introduction of Aisi304 SS Wire Cloth has revolutionized filtration systems, offering unparalleled performance across a wide range of industries. Its superior corrosion resistance, durability, and versatility make it the go-to choice for professionals worldwide. As industries continue to evolve, rely on the durability and efficiency of Aisi304 SS Wire Cloth to meet your filtration needs.

Durable and Versatile Copper Mesh Cloth: A Practical Solution for Numerous Applications

Title: Innovative Copper Mesh Cloth Revolutionizes Industries, Paving the Way for Sustainable SolutionsIntroduction:Innovation is at the core of the modern world, paving the way for sustainable solutions that address environmental, social, and economic challenges. One such groundbreaking innovation is Copper Mesh Cloth, a versatile material that has transformed numerous industries. In this article, we shed light on the remarkable features of Copper Mesh Cloth and explore its impact on various sectors globally. I. Understanding Copper Mesh Cloth:Copper Mesh Cloth, a revolutionary material developed by a leading industrial solutions provider, combines the unique properties of copper with an intricate cloth structure. This innovative design creates a durable, flexible, and electrically conductive mesh, opening up a world of possibilities for different applications. The mesh is comprised of copper threads woven together to create a seamless and efficient fabric.II. Environmental Applications:1. Air Filtration Systems: Copper Mesh Cloth's antimicrobial and antiviral properties make it ideal for air filtration systems. It effectively traps microorganisms, dust particles, and allergens, ensuring clean air circulation in sensitive environments such as hospitals, laboratories, and manufacturing units.2. Water Filtration Systems: The mesh's ability to capture and remove impurities and bacteria from water has made it a game-changer in the water purification industry. Copper Mesh Cloth enables the development of sustainable and eco-friendly water filtration systems that are both effective and durable.III. Industrial Applications:1. Electrical Conductivity: Copper is renowned for its exceptional electrical conductivity. Thus, Copper Mesh Cloth finds extensive use in electrical and electronic industries as connectors, grounding systems, and electromagnetic shielding. Its durability and flexibility make it an ideal choice for complex wiring systems in automobiles, aerospace, and telecommunications.2. Heat Exchange Components: The exceptional thermal conductivity of copper makes Copper Mesh Cloth an ideal material for heat exchange components, such as heat sinks and heat exchangers. It efficiently transfers heat from high-temperature sources and dissipates it, resulting in enhanced energy efficiency and extended equipment lifespan.IV. Agriculture and Pest Control:1. Pest Deterrence: Copper Mesh Cloth, when installed in buildings or around plants, acts as an effective barrier against rodents, insects, and other pests. Its durability, resistance to corrosion, and malleability make it easy to install and maintain in agricultural and residential settings.2. Organic Crop Protection: Copper's natural antimicrobial properties have been acknowledged for centuries. Copper Mesh Cloth provides organic farmers with an effective and sustainable solution to combat various crop diseases, thereby reducing the need for harmful chemical pesticides.V. COVID-19 Mitigation:1. Face Masks: Copper Mesh Cloth has gained attention during the COVID-19 pandemic due to its antimicrobial properties. It is being used as a filter material in high-quality masks, capable of trapping and neutralizing viruses and bacteria more effectively than traditional filters.2. Touch-Surface Coatings: The antimicrobial properties of Copper Mesh Cloth also make it suitable for coatings on frequently touched surfaces, such as doorknobs, handrails, and elevator buttons. This reduces the risk of germ transmission in public spaces, promoting safer environments.Conclusion:Copper Mesh Cloth has transformed numerous industries through its versatility, durability, and unique properties. Its applications range from air and water filtration to electrical conductivity and pest control. Moreover, it has proven instrumental in combatting the COVID-19 pandemic by providing efficient solutions for face masks and touch-surface coatings. As the world increasingly embraces sustainable and innovative solutions, Copper Mesh Cloth stands as a beacon of hope, promising a brighter and cleaner future for all.

Welded Wire Mesh Manufacturer Innovates with Stainless Steel Materials

In the current market scenario, there is a growing demand for high-quality industrial tools and equipment across different industries. One such industry that is witnessing a high demand for durable, efficient and long-lasting equipment is the construction and manufacturing industry. With this in mind, the Stainless Steel Welded Wire Mesh Factory, situated in China, is providing premium quality welded wire mesh to its clients.The Stainless Steel Welded Wire Mesh Factory is a prominent entity in the welded mesh industry. With over ten years of experience, the factory has achieved a high level of expertise in the manufacturing of welded wire meshes. The company takes pride in its knowledgeable and skilled workforce, which is capable of producing high-quality products designed to meet the specific requirements of customers. The factory operates out of a massive 6,000 square meters facility, allowing for the production of large quantities of welded wire mesh for various applications.Stainless Steel Welded Wire Mesh is made by welding wires together in different patterns to form a square or rectangular mesh structure. The wire mesh is called "Stainless Steel" because it is made from high-quality stainless steel, which ensures the final product to be corrosion-resistant and highly durable. The process of welding the wires together strengthens the wire mesh and makes it more efficient and long-lasting. The mesh is becoming increasingly popular in the construction and manufacturing industries due to its versatility and strength.The Stainless Steel Welded Wire Mesh Factory understands the value of quality and durability, which is why they use the best quality raw materials available in the market. The company's machines are of the highest quality, which helps in producing precision-welded wire meshes that meet the exact specifications of the customers. The factory's team of engineers and technicians regularly upgrade their sector-specific knowledge and skills, enabling them to provide consistent, high-quality products to their clients.Some of the top applications of stainless-steel welded wire mesh include fencing, partitions, storage cages, decks, and gabion mesh. In addition to these applications, the wire mesh has found its way into several industrial processes, including filtration, sieving, and sparging processes. With its versatility and sturdiness, the Stainless Steel Welded Wire Mesh factory can provide custom-built meshes for clients' specific applications.The company has built its reputation on quality and timely delivery, and this is evident in its commitment to customer satisfaction. The company offers affordable prices to its customers while ensuring that the products are delivered within the stipulated time frame.At the Stainless Steel Welded Wire Mesh Factory, quality control is a top priority. Every stage of the manufacturing process is closely monitored, from the selection of raw materials to the final packaging of the finished product. The company uses advanced testing equipment to ensure that the wire mesh produced meets the desired quality criteria, including tensile strength, corrosion resistance, and structural stability.In conclusion, the Stainless Steel Welded Wire Mesh Factory is a leader in the production of welded wire mesh, providing quality and durable products to clients across different industries. The company's commitment to quality, precision, and timely delivery has helped it build a loyal customer base. With its highly knowledgeable and skilled workforce, state-of-the-art equipment, and stringent quality control processes, the factory is positioned to meet the demands of the ever-growing market for welded wire mesh.

Ultimate Guide to Steel Wire Cloth: Everything You Need to Know

Steel Wire Cloth provides reliable and durable filtering solutions which are widely used in industries ranging from aerospace to automotive, mining to food processing, and everything in between. Their high-quality products are made from top-notch materials sourced from trusted suppliers, ensuring consistent performance and long-lasting durability. Additionally, their team of experienced professionals provides exceptional customer service, ensuring that their clients' needs are met with efficiency and precision.Steel Wire Cloth quickly gained fame across a wide range of industries due to its innovative approach to manufacturing filtering solutions. The company's founder, John Smith, recognized the need for high-quality, specialized filters that could handle tough conditions. So, he set out to create a company that could deliver the most reliable and efficient filtering products on the market. He hired a team of experts with years of experience in manufacturing filtering solutions, and soon, Steel Wire Cloth was born.Today, Steel Wire Cloth is one of the leading manufacturers of filters for a variety of industries, providing top-of-the-line performance to its customers. The company offers a wide range of products, including wire mesh filters, woven wire cloth, custom filtration solutions, and much more. They have mastered the art of precision manufacturing, ensuring that their filters meet the exact specifications required by their clients in the most demanding conditions.Steel Wire Cloth can customize filtration products according to the needs of their clients via utilizing the latest technology. This customization allows them to enhance the efficiency of their filters and meet the exact specifications necessary for specific projects. Furthermore, the company's team members have decades of combined experience in designing and crafting filters. With this expertise, they can develop highly specialized filters that perform exceptionally well in even the harshest conditions. This ability to customize filtering products has made Steel Wire Cloth one of the most trusted filter manufacturers in the industry. Steel Wire Cloth's products are used across a wide range of industries, including aerospace, automotive, mining, pharmaceuticals, and food processing. Their filters are used to separate molten metals, separate impurities from liquids, and to sift through powders in industries across the globe. Regardless of the application, they constantly strive to deliver high-quality products, meeting the needs of their customers with excellence.Steel Wire Cloth prides itself on its highest standards of customer service, providing quality assurance for every product manufactured. Their main goal is to provide their customers with the most reliable and cost-effective filtering solutions for their specific applications. They work hard to ensure that their products meet the strictest industry standards and regulations. Additionally, they offer expert advice on choosing the perfect filter for each industry application.In conclusion, Steel Wire Cloth has become one of the most respected companies in the filtration industry due to its innovative filter designs, exceptional customer service, and stringent performance standards. They are continuously expanding their knowledge and technological expertise, making them the go-to company for clients in various industries. They have a reputation for delivering durable, high-performance filters that surpass the needs of their clients, making them the preferred choice for all filtration needs.

Sintered Metal Filter Elements: The Best Solution for Filtration Needs

Sintered Metal Filter Elements: The Ultimate Solution for Industrial FiltrationIn today's industrial environment, the importance of filters cannot be overstated. Filters are an essential component of any manufacturing process as they help to prevent harmful particles from entering products during the production process. One such type of filter that has gained immense popularity in recent years is sintered metal filter elements. These elements are made up of sintered metal powders and are used in a variety of applications including liquid and gas filtration. In this article, we will discuss the benefits of using sintered metal filter elements, and introduce a company that specializes in manufacturing these high-quality products.Benefits of Using Sintered Metal Filter ElementsOne of the primary benefits of using sintered metal filter elements is their ability to withstand high temperatures. They are capable of withstanding temperatures ranging from -200 to 1000°C which makes them ideal for use in high-temperature applications. Additionally, these filter elements offer excellent resistance to corrosion and erosion. They are capable of working in harsh environments and are highly resistant to chemicals, acids, and bases.Another advantage of sintered metal filter elements is their high filtration efficiency. They are designed to provide superior filtration and can capture even the smallest particles present in a liquid or gas medium. This makes them ideal for applications in the food and beverage industry where even the smallest impurities can cause contamination.Sintered metal filter elements are also highly durable and long-lasting. They are made up of high-quality metal powders that are sintered together to form a strong, robust structure. This ensures that they can withstand high pressure and mechanical stress without compromising their filtration efficiency. Additionally, sintered metal filter elements are easy to clean and maintain which makes them a cost-effective solution for industrial filtration.{} Company - A Leading Manufacturer of Sintered Metal Filter Elements{} Company is a well-known name in the field of industrial filtration. The company has been designing and manufacturing sintered metal filter elements for over 30 years and is a leading supplier of these products worldwide.{} Company's sintered metal filter elements are designed for high performance and are available in a variety of shapes, sizes, and materials to meet the specific needs of different industries. The company's product range includes sintered metal filter discs, filter cartridges, filter baskets, and filter plates.{} Company has a state-of-the-art manufacturing facility equipped with advanced production equipment and technology. Their team of skilled engineers and technicians work tirelessly to ensure that each product is of the highest quality. {} Company is committed to providing its customers with the best products and services to meet their industrial filtration needs.ConclusionSintered metal filter elements are an essential part of any industrial filtration process. Their ability to withstand high temperatures, resist corrosion and erosion, and provide high filtration efficiency makes them an ideal choice for a variety of industries. To ensure that you get the best quality sintered metal filter elements, it is essential to choose a reputable manufacturer like {} Company that has a proven track record of delivering high-quality products and exceptional service.

Exploring the Features and Applications of Woven Wire Mesh: An In-depth Look

article as follows:Brass Woven Wire Mesh A Major Breakthrough In Metal FabricationWire mesh fabrication technology has come a long way in recent years. Today, producers can develop a wide array of wire mesh products that meet different customer needs. Among the wire mesh products that have taken the industry by storm is the brass woven wire mesh.Brass woven wire mesh (we will remove the brand name for this purpose) is made from high-quality brass materials that have undergone a series of manufacturing processes. The result is a unique mesh product that is strong, durable, and highly versatile.The innovative brass woven wire mesh is a major breakthrough in the metal fabrication industry. It is a flexible, lightweight, and highly modifiable product that weaves together different strands of brass wires into various mesh shapes and sizes. The design of the brass woven wire mesh allows for easy customization of mesh specifications based on unique application requirements.The attributes of brass woven wire mesh make it an ideal material for use in various industries. Businesses that require high-quality wire mesh products can use this mesh for filtration purposes, as a decorative element, and for applications requiring a barrier. This versatility has made brass woven wire mesh a popular choice among manufacturers in the automotive industry, construction industry, and even the arts and crafts sector.The brass woven wire mesh is an excellent choice for filtration purposes. Its intricate weaving pattern allows for the passage of fluids without allowing debris or other particles to pass through. This quality makes it an ideal material for use in industries that require filtration of air and liquids, such as the pharmaceutical and food industries.Brass woven wire mesh is also a popular choice in the automotive industry where it is often used for airbags. Its strength and durability make it an ideal choice for this application.In the construction industry, brass woven wire mesh is used to reinforce metal fabrication products, such as steel structures. Its unique attributes make it a reliable option for providing support and enhancing the structural integrity of large structures.Brass woven wire mesh is also a widely used decorative element in both commercial and residential applications. Its versatility allows it to be easily modified, making it possible to create unique and original designs that enhance the aesthetics of the space.Manufacturers of brass woven wire mesh employ state-of-the-art technology, high-quality raw materials, and rigorous quality control measures to ensure that their products meet industry standards. This commitment to quality and innovation has set companies that produce this mesh apart from their competitors.Our temporary pared-down mention of a brand name also underscores the importance of choosing the right supplier in this industry. When selecting a supplier, manufacturers should consider the supplier's experience, cost, and quality of products. The right supplier should be able to work with manufacturers to provide customized mesh solutions that meet their specific application needs.In conclusion, brass woven wire mesh is a groundbreaking mesh product that has revolutionized the metal fabrication industry. Its unique attributes make it an ideal material for use in various industries, including filtration, automotive, construction, decorative, and art applications. Manufacturers need to work with reliable suppliers of brass woven wire mesh to ensure that they get high-quality products that meet their specific industry requirements.

Global Market Report Covers Woven Cloth For Copper by Types, Applications, Regions, and Manufacturers in 2020

Woven Copper Cloth: A Global Market AnalysisIn recent years, the global copper market has witnessed significant growth, driven by the increasing demand for copper-based products in various industries. One such product gaining traction is woven copper cloth. Woven copper cloth, also known as copper mesh, is a versatile material that finds applications across a wide range of sectors, including electronics, construction, filtration, and automotive. This blog will delve into the global analysis of the woven copper cloth market, exploring its market size, applications, regions of dominance, and key manufacturers.Market Size of Woven Copper ClothThe woven copper cloth market has experienced steady growth in recent years, owing to its exceptional conductive properties and versatility. According to market reports, the global woven copper cloth market is projected to witness a compound annual growth rate (CAGR) of X% during the forecast period (2020-2025). This projected growth is attributed to the increasing demand for woven copper cloth in various applications.Applications of Woven Copper ClothWoven copper cloth finds extensive applications in diverse industries. Its exceptional electrical conductivity and stability make it an ideal material for electronic products. It is commonly used in the production of electronic printed circuit boards (PCBs) and electromagnetic shielding devices. The automotive industry also utilizes woven copper cloth for applications such as gaskets, connectors, and heat exchangers due to its thermal conductivity and corrosion resistance.Additionally, woven copper cloth serves as an essential component in the construction industry. It is used for the reinforcement of concrete structures, preventing cracking and enhancing durability. Moreover, the filtration industry benefits from its excellent filtration properties, making it suitable for applications in air and liquid filtration systems.Regions Dominating the Woven Copper Cloth MarketThe woven copper cloth market showcases a broad geographical presence, with key regions contributing to its growth. North America, Europe, and Asia-Pacific (APAC) are the primary regions dominating the global market. North America holds the largest market share, primarily driven by the presence of major manufacturers and significant demand from industries such as electronics and automotive.Europe is expected to witness substantial market growth due to the increasing adoption of woven copper cloth in the construction and filtration sectors. The growing emphasis on sustainable construction practices and the need for efficient filtration systems drive the demand in this region.The APAC region is foreseen as the fastest-growing market for woven copper cloth. Rapid industrialization, the expanding electronics sector, and the increasing adoption of copper-based products in emerging economies like China and India are propelling the market's growth in this region.Key Manufacturers of Woven Copper ClothSeveral prominent manufacturers cater to the global woven copper cloth market. However, some key players have consistently demonstrated their dominance in the market. They include Boegger Industrial Limited, Brown-Campbell Company, Dorstener Wire Tech Inc., and Edward J Darby & Son, Inc.Boegger Industrial Limited, a leading player in the market, offers a diverse range of woven copper cloth products tailored to specific industry requirements. They provide customized solutions and maintain the highest quality standards to meet customer expectations.Brown-Campbell Company specializes in manufacturing woven copper mesh with different weave patterns and wire diameters. Their products are known for their excellent durability and electrical conductivity.Dorstener Wire Tech Inc. focuses on providing woven copper cloth that meets stringent filtration requirements. Their products are widely used in air and liquid filtration applications across various industries, ensuring high-quality performance.Edward J Darby & Son, Inc. is renowned for its extensive range of woven copper cloth, catering to applications in electronics, automotive, and construction sectors. Their commitment to innovation and customer satisfaction has propelled their market presence.In conclusion, the global woven copper cloth market is poised for significant growth in the coming years. Its versatile applications, exceptional properties, and the increasing demand from multiple industries contribute to its market expansion. As the need for efficient and sustainable solutions persists, woven copper cloth will continue to play a crucial role in various sectors across the globe.Keywords: woven copper cloth, global market analysis, market size, applications, regions, manufacturers.

Wire Mesh Stainless Steel: A Reliable Solution for Your Distribution Needs

[Company Name] Introduces Innovative Applications of Wire Mesh Stainless Steel[Place], [Date] - [Company Name], a renowned leader in the wire mesh industry, has recently unveiled their latest line of innovative applications for stainless steel wire mesh. Known for their commitment to quality, reliability, and superior customer service, [Company Name] has established itself as a trusted name in the industry.With years of experience and expertise in wire mesh manufacturing, [Company Name] has been at the forefront of developing cutting-edge solutions for a wide range of industries. Their advanced wire mesh products are widely used in automotive, aerospace, construction, filtration, and many other applications.Stainless steel wire mesh is known for its exceptional strength, durability, and resistance to corrosion. These qualities make it an ideal material for various applications where reliability and performance are of paramount importance. [Company Name] has further enhanced the properties of stainless steel wire mesh through their research and development efforts, resulting in innovative applications that push the boundaries of its potential.One of the primary areas where [Company Name] has made significant advancements is in the field of filtration. The company's wire mesh filters offer superior performance in various industries, including oil and gas, pharmaceuticals, food and beverage, and water treatment. These filters effectively remove impurities and contaminants, ensuring a clean and safe output.In the automotive and aerospace sectors, [Company Name] has designed specialized wire mesh products that provide high-strength reinforcement for composite materials. These composites are used to reduce weight while maintaining structural integrity, resulting in fuel efficiency and improved performance.Additionally, [Company Name] has expanded its product portfolio to cater to the growing demand for architectural wire mesh. Architects and designers can now utilize the company's aesthetically pleasing and durable stainless steel mesh for applications such as facades, interior partitioning, sunscreens, and decorative elements. The versatility of stainless steel wire mesh allows for endless creativity and customization to achieve stunning visual effects.To ensure the highest levels of quality, [Company Name] utilizes state-of-the-art manufacturing techniques and machinery. Their skilled technicians meticulously inspect each product to guarantee compliance with industry standards and customer specifications. Moreover, the company maintains a comprehensive quality control system, which includes regular testing and certification."By focusing on continuous innovation and customer satisfaction, we have been able to establish ourselves as a market leader in the wire mesh industry," said [Company Representative], CEO of [Company Name]. "We are committed to providing our customers with the best solutions for their specific needs, and our latest lineup of wire mesh stainless steel applications reflects that dedication."As a testament to their commitment to environmental sustainability, [Company Name] also adheres to eco-friendly manufacturing practices. The company ensures responsible waste management and minimizes its carbon footprint by investing in energy-efficient technologies.With their unrivaled expertise and diverse product range, [Company Name] is poised to take the wire mesh industry to new heights. By consistently delivering high-quality solutions, the company has earned the trust and loyalty of customers worldwide.For more information about [Company Name] and their innovative applications of wire mesh stainless steel, please visit their website [Website URL] or contact their sales team at [Contact Number].

Durable and Versatile Steel Mesh Cloth: A Cost-Effective Solution for Various Applications

Steel Mesh Cloth Takes the Construction Industry by StormIn an industry that is constantly seeking innovative and efficient solutions, the introduction of Steel Mesh Cloth has brought a breath of fresh air to the construction sector. Developed by a renowned company known for its pioneering spirit and commitment to excellence, this revolutionary material is changing the way projects are completed and elevating construction practices to a new level. With its superior strength, versatility, and durability, Steel Mesh Cloth has quickly become the go-to choice for many construction professionals.Traditionally, construction sites heavily relied on steel bars and concrete reinforcement to provide structural support and enhance the overall strength of buildings. However, these traditional methods were time-consuming, costly, and often required painstaking installation. Recognizing these limitations, the innovative team at [Company Name] set out to develop a solution that would revolutionize the construction industry. The result, Steel Mesh Cloth, has quickly garnered attention and acclaim.The key advantage of Steel Mesh Cloth lies in its ease of use and installation. Unlike steel bars, which need to be carefully cut, bent, and placed, Steel Mesh Cloth comes in pre-made sheets that can be easily laid out and secured. This not only saves valuable time but also reduces the margin of error during installation. Construction professionals can now complete projects with greater efficiency and precision, ultimately leading to increased productivity and reduced construction costs.But it's not just the ease of installation that sets Steel Mesh Cloth apart. This innovative material boasts impressive strength and durability, making it an ideal choice for a wide range of applications. Whether used for reinforcing concrete, providing stability to retaining walls, or increasing the load-bearing capacity of floors and decks, Steel Mesh Cloth delivers exceptional performance. Its robust structure ensures that buildings can withstand extreme weather conditions, heavy loads, and the test of time.What truly separates Steel Mesh Cloth from its competitors is its versatility. Available in various sizes and configurations, this material can be customized to suit the specific requirements of any construction project. Whether working on a residential, commercial, or industrial site, construction professionals can rely on Steel Mesh Cloth to provide the necessary support and reinforcement. Its flexibility allows for creative design possibilities, giving architects and engineers more freedom to realize their vision.In addition to its technical superiority, Steel Mesh Cloth also boasts environmental benefits. Manufactured using sustainable practices and using recycled materials, this material supports the construction industry's efforts towards sustainability and reducing its carbon footprint. Its long lifespan further contributes to the eco-friendly nature of Steel Mesh Cloth, as it reduces waste and the need for frequent replacements.The success of Steel Mesh Cloth can be seen in the numerous construction projects that have embraced this innovative solution. From bridges and highways to residential buildings and skyscrapers, Steel Mesh Cloth is transforming the construction landscape. Its numerous advantages have not only simplified the construction process but have also improved project outcomes, ensuring safer and more resilient structures.As the construction industry continues to evolve, the demand for efficient and reliable materials will only increase. Steel Mesh Cloth, with its exceptional qualities, is perfectly positioned to meet these demands head-on. With its ease of installation, strength, versatility, and environmental benefits, this revolutionary material has already proven its worth in the construction world, and its future looks brighter than ever.