Understanding the Applications and Benefits of Woven Wire Fabric

By:Admin

One of the leading providers of woven wire fabric is {Company Name}, a renowned manufacturer and distributor of high-quality wire mesh products. With a commitment to delivering top-notch products and exceptional customer service, {Company Name} has established itself as a trusted partner for businesses across a wide range of industries.

The roots of {Company Name} can be traced back to its humble beginnings, where it started as a small wire fabric weaving operation. Over the years, the company has grown and expanded its product offerings to include a comprehensive range of woven wire fabric products to meet the diverse needs of its customers.

One of the key factors that sets {Company Name} apart from its competitors is its dedication to quality. Each woven wire fabric produced by the company undergoes rigorous testing and quality control measures to ensure that it meets the highest standards of performance and durability. This commitment to quality has earned {Company Name} a reputation for providing reliable and premium-grade wire mesh products.

Furthermore, {Company Name} prides itself on its ability to customize woven wire fabric to suit the specific requirements of its customers. Whether it's a unique size, shape, or material composition, the company's team of experienced engineers and technicians work closely with clients to develop tailored solutions that precisely match their needs. This level of customization sets {Company Name} apart in the industry and has solidified its position as a go-to supplier for custom wire mesh products.

In addition to its dedication to quality and customization, {Company Name} places a strong emphasis on innovation and technological advancement. The company constantly invests in research and development to enhance its manufacturing processes and product offerings. This commitment to innovation has allowed {Company Name} to stay at the forefront of the industry, offering cutting-edge woven wire fabric solutions that meet the evolving needs of its customers.

Moreover, {Company Name} takes great pride in its customer-centric approach. The company goes above and beyond to provide exceptional support and expertise to its clients, offering technical guidance, practical solutions, and on-time delivery to ensure a seamless experience for its customers. This dedication to customer satisfaction has earned {Company Name} a loyal and satisfied customer base, further establishing its reputation as a reliable and trusted partner in the industry.

With a strong focus on quality, customization, innovation, and customer satisfaction, {Company Name} continues to set the benchmark for excellence in the woven wire fabric industry. As the demand for high-quality wire mesh products continues to grow, {Company Name} remains committed to delivering top-notch solutions that meet the diverse and evolving needs of its customers.

In conclusion, woven wire fabric has become an indispensable material in various industries, and {Company Name} stands out as a leading provider of premium-grade wire mesh products. With a rich history, a commitment to quality, a focus on innovation, and a customer-centric approach, {Company Name} has solidified its position as a trusted partner for businesses seeking reliable and customized woven wire fabric solutions. As the company continues to grow and expand its product offerings, it is poised to remain at the forefront of the industry for years to come.

Company News & Blog

Global Market Report Covers Woven Cloth For Copper by Types, Applications, Regions, and Manufacturers in 2020

Woven Copper Cloth: A Global Market AnalysisIn recent years, the global copper market has witnessed significant growth, driven by the increasing demand for copper-based products in various industries. One such product gaining traction is woven copper cloth. Woven copper cloth, also known as copper mesh, is a versatile material that finds applications across a wide range of sectors, including electronics, construction, filtration, and automotive. This blog will delve into the global analysis of the woven copper cloth market, exploring its market size, applications, regions of dominance, and key manufacturers.Market Size of Woven Copper ClothThe woven copper cloth market has experienced steady growth in recent years, owing to its exceptional conductive properties and versatility. According to market reports, the global woven copper cloth market is projected to witness a compound annual growth rate (CAGR) of X% during the forecast period (2020-2025). This projected growth is attributed to the increasing demand for woven copper cloth in various applications.Applications of Woven Copper ClothWoven copper cloth finds extensive applications in diverse industries. Its exceptional electrical conductivity and stability make it an ideal material for electronic products. It is commonly used in the production of electronic printed circuit boards (PCBs) and electromagnetic shielding devices. The automotive industry also utilizes woven copper cloth for applications such as gaskets, connectors, and heat exchangers due to its thermal conductivity and corrosion resistance.Additionally, woven copper cloth serves as an essential component in the construction industry. It is used for the reinforcement of concrete structures, preventing cracking and enhancing durability. Moreover, the filtration industry benefits from its excellent filtration properties, making it suitable for applications in air and liquid filtration systems.Regions Dominating the Woven Copper Cloth MarketThe woven copper cloth market showcases a broad geographical presence, with key regions contributing to its growth. North America, Europe, and Asia-Pacific (APAC) are the primary regions dominating the global market. North America holds the largest market share, primarily driven by the presence of major manufacturers and significant demand from industries such as electronics and automotive.Europe is expected to witness substantial market growth due to the increasing adoption of woven copper cloth in the construction and filtration sectors. The growing emphasis on sustainable construction practices and the need for efficient filtration systems drive the demand in this region.The APAC region is foreseen as the fastest-growing market for woven copper cloth. Rapid industrialization, the expanding electronics sector, and the increasing adoption of copper-based products in emerging economies like China and India are propelling the market's growth in this region.Key Manufacturers of Woven Copper ClothSeveral prominent manufacturers cater to the global woven copper cloth market. However, some key players have consistently demonstrated their dominance in the market. They include Boegger Industrial Limited, Brown-Campbell Company, Dorstener Wire Tech Inc., and Edward J Darby & Son, Inc.Boegger Industrial Limited, a leading player in the market, offers a diverse range of woven copper cloth products tailored to specific industry requirements. They provide customized solutions and maintain the highest quality standards to meet customer expectations.Brown-Campbell Company specializes in manufacturing woven copper mesh with different weave patterns and wire diameters. Their products are known for their excellent durability and electrical conductivity.Dorstener Wire Tech Inc. focuses on providing woven copper cloth that meets stringent filtration requirements. Their products are widely used in air and liquid filtration applications across various industries, ensuring high-quality performance.Edward J Darby & Son, Inc. is renowned for its extensive range of woven copper cloth, catering to applications in electronics, automotive, and construction sectors. Their commitment to innovation and customer satisfaction has propelled their market presence.In conclusion, the global woven copper cloth market is poised for significant growth in the coming years. Its versatile applications, exceptional properties, and the increasing demand from multiple industries contribute to its market expansion. As the need for efficient and sustainable solutions persists, woven copper cloth will continue to play a crucial role in various sectors across the globe.Keywords: woven copper cloth, global market analysis, market size, applications, regions, manufacturers.

Efficient and Reliable Filter Elements for Improved Filtration Performance: A Comprehensive Review

Title: Industry-Leading Epe Filter Element Revolutionizes Filtration TechnologyIntroduction:In a groundbreaking development, a renowned filtration company has unveiled its latest innovation, the Epe Filter Element. With advanced features and cutting-edge technology, this remarkable filtration component sets a new industry standard. Designed to provide superior filtration performance across various sectors, the Epe Filter Element offers remarkable efficiency and reliability. This news article explores the exceptional attributes of the filter element and highlights its potential applications in diverse fields.Unleashing Advanced Filtration Capabilities:The Epe Filter Element is a result of extensive research and development by a leading filtration solutions provider. It incorporates state-of-the-art filtration media and construction techniques to ensure unparalleled efficiency. By utilizing a specialized surface-modification technology, the filter element enhances the filtration process while maintaining optimal flow rates. It effectively captures and removes impurities, ensuring cleaner and safer operating environments.Unmatched Efficiency and Exceptional Performance:One of the key features of the Epe Filter Element is its extraordinary filtration efficiency. The meticulously engineered filtration media and design enable the element to efficiently trap contaminants, ensuring high-quality filtration. This exceptional performance offers significant benefits in critical applications, including oil and gas, automotive, pharmaceuticals, electronics, and food processing industries.Furthermore, the Epe Filter Element surpasses traditional filtration methods by extending the service life and reducing maintenance costs. Its robust design and self-cleaning mechanism prevent clogging and enable continuous operation, resulting in improved productivity and reduced downtime. This aspect makes the filter element an indispensable asset in industries where uninterrupted operation is paramount.Versatility: Applications Across IndustriesThe versatility of the Epe Filter Element is evident in its wide range of applications across various industries. In the oil and gas sector, the filter element ensures the purity of lubricants, preventing equipment wear and optimizing operational efficiency. It is also suitable for use in automotive manufacturing, where it guarantees clean hydraulic systems and component longevity.The pharmaceutical industry greatly benefits from the Epe Filter Element's ability to deliver ultra-pure filtered solutions. It ensures that medications and vaccines are free from contaminants and meet stringent industry standards for quality and safety. Additionally, the electronics industry relies on this advanced filter element to maintain clean manufacturing environments necessary for high-precision electronic component production.Food processing companies utilize the Epe Filter Element to achieve exceptional product quality and adherence to strict hygiene standards. By removing impurities, it guarantees that food products meet regulatory requirements and customer expectations. These diverse applications emphasize the versatility and efficiency of the Epe Filter Element in enhancing filtration processes across multiple sectors.Environmental Responsibility and Sustainability:Moreover, sustainability plays a key role in the design and production of the Epe Filter Element. The company actively pursues eco-friendly manufacturing practices and materials, ensuring that the filter element aligns with global environmental regulations. By reducing energy consumption and minimizing waste, the company demonstrates its commitment to a greener future while providing superior filtration solutions.Conclusion:With its revolutionary design, exceptional performance, and versatile applications, the Epe Filter Element establishes itself as a game-changer in the filtration industry. Its advanced features ensure efficiency, reliability, and durability. By addressing the varying needs of industries such as oil and gas, automotive, pharmaceuticals, electronics, and food processing, this filter element transforms filtration processes and sets higher industry standards. With its commitment to sustainability, the company behind the Epe Filter Element demonstrates a dedication to both customer satisfaction and environmental responsibility.

Quality Crimped Wire Mesh Manufacturers for Your Project

Crimped Wire Mesh Manufacturers are proud to announce their latest advancements in the production of high-quality wire mesh products. With a commitment to precision engineering and quality craftsmanship, they have established themselves as a leader in the industry.The company, with its extensive experience and expertise in wire mesh manufacturing, has been catering to a wide range of industries including construction, mining, agriculture, and petrochemical. They offer a diverse range of wire mesh products, including stainless steel crimped wire mesh, galvanized crimped wire mesh, and heavy duty crimped wire mesh. Their products are well-known for their durability, strength, and resistance to corrosion, making them ideal for demanding applications.The crimped wire mesh manufactured by the company is made from high-quality raw materials, ensuring superior performance and longevity. Their state-of-the-art manufacturing facilities are equipped with advanced machinery and technology, enabling them to produce wire mesh products that meet the highest industry standards.In addition to their standard product offering, Crimped Wire Mesh Manufacturers also provide custom wire mesh solutions to meet specific customer requirements. They work closely with their clients to understand their unique needs and provide tailored wire mesh solutions that perfectly fit their specifications. The company’s commitment to customer satisfaction and product quality has earned them a solid reputation in the industry.The company’s dedication to quality extends beyond their products to their customer service and support. They have a team of highly skilled and experienced professionals who are committed to providing exceptional service to their clients. Whether it’s technical assistance, product recommendations, or after-sales support, the team at Crimped Wire Mesh Manufacturers is always ready to assist their customers.One of the key factors that sets Crimped Wire Mesh Manufacturers apart from their competitors is their focus on innovation and continuous improvement. They are constantly investing in research and development to enhance their manufacturing processes and develop new and improved wire mesh products. This dedication to innovation has allowed them to stay ahead of the competition and cement their position as a leading wire mesh manufacturer.The company is also dedicated to sustainability and environmental responsibility. They adhere to strict environmental regulations and guidelines in their manufacturing processes, ensuring that their operations have minimal impact on the environment. Additionally, they are committed to reducing waste and maximizing resource efficiency throughout their production processes.Crimped Wire Mesh Manufacturers also prioritize workplace safety and employee well-being. They have implemented comprehensive safety protocols and policies to ensure a safe and healthy work environment for their staff. They also provide ongoing training and development opportunities to empower their employees and help them reach their full potential.As a testament to their commitment to quality and excellence, Crimped Wire Mesh Manufacturers have earned several certifications and accolades for their products and manufacturing processes. Their adherence to international quality standards and regulations has made them a trusted and reliable partner for companies across various industries.In conclusion, Crimped Wire Mesh Manufacturers’ dedication to quality, innovation, and customer satisfaction has positioned them as a leader in the wire mesh manufacturing industry. With a strong focus on product quality, customer service, and environmental responsibility, they continue to set the standard for excellence in the industry. Whether it’s standard wire mesh products or custom solutions, customers can trust Crimped Wire Mesh Manufacturers to deliver superior quality products and unmatched service.

Metal Woven Copper Wire Mesh for Industrial Use, Packed in Rolls at Rs 150/Meter

Title: The Versatility of Copper Wire Mesh Roll: Ideal for Industrial ApplicationsIntroduction:Copper wire mesh has gained significant popularity in various industries due to its exceptional properties and versatility. This blog will delve into the applications and benefits of metal woven copper wire mesh, particularly in its roll packaging form. With a focus on industrial usage, we will explore the features, advantages, and key considerations of this product. Additionally, we will highlight the benefits of incorporating copper wire mesh roll and its impact on various industries.1. Understanding Copper Wire Mesh Roll:Copper wire mesh, available in a roll packaging type, presents an easily adaptable and flexible solution for numerous industrial applications. This woven mesh is crafted using highly durable copper wires, ensuring excellent tensile strength, conductivity, and longevity.2. Importance of Copper Wire Mesh in Industrial Applications:The industrial sector greatly benefits from the utilization of copper wire mesh roll due to its diverse range of properties and applications. Some key areas where copper mesh finds value are:a. Filtration and Separation:Copper wire mesh offers outstanding filtration capabilities, making it ideal for separating solids from liquids or gases. The fine mesh size options ensure effective separation of particles, making it valuable in industries such as petrochemicals, pharmaceuticals, and food processing.b. Electrical Applications:Copper wire mesh is highly conductive, making it an excellent choice for various electrical applications. Its electrical conductivity properties allow for efficient current flow, making copper mesh roll suitable for transformers, power generation, electronics, and more.c. Anti-Insect Screens:Copper wire mesh roll finds application as an effective anti-insect screen due to its durability and corrosion resistance. It acts as a protective barrier in windows, doors, or vents, preventing the entry of insects while still maintaining airflow.d. EMI and RFI Shielding:Copper wire mesh roll is also widely utilized for EMI (Electromagnetic Interference) and RFI (Radio Frequency Interference) shielding in industries dealing with sensitive electronic equipment. Its high conductivity and mesh design effectively divert electromagnetic waves, ensuring the safety and proper functioning of electronic devices.3. Advantages of Copper Wire Mesh Roll:Incorporating copper wire mesh roll in industrial processes offers several advantages that set it apart from other alternatives:a. High Strength and Durability:Copper wire mesh roll displays remarkable tensile strength, enabling it to withstand high temperatures, pressure, and abrasive environments. Its excellent corrosion resistance further enhances its durability, making it a long-lasting solution.b. Excellent Conductivity:The exceptional electrical conductivity of copper wire mesh ensures efficient current flow, reducing energy loss and improving performance in electrical applications. This property enables it to act as a reliable conductor, particularly essential in electrical and electronics industries.c. Easy Adaptability:Copper wire mesh roll can be easily tailored to meet specific application requirements. Its flexibility and versatility allow it to fit seamlessly into various industrial processes, including custom filtration systems and shielding applications.d. Environmental Sustainability:Copper is a recyclable material, making copper wire mesh roll an environmentally friendly choice. Its sustainability factor adds value to industries seeking greener alternatives while still maintaining the desired functionality.Conclusion:The metal woven copper wire mesh roll emerges as a versatile solution for a range of industrial applications. Its superior strength, flexibility, electrical conductivity, and recyclability make it an ideal choice for sectors such as filtration, electrical, insect screening, and EMI/RFI shielding. With its numerous advantages, copper wire mesh roll continues to play a pivotal role in enhancing efficiency, productivity, and performance across various industries.

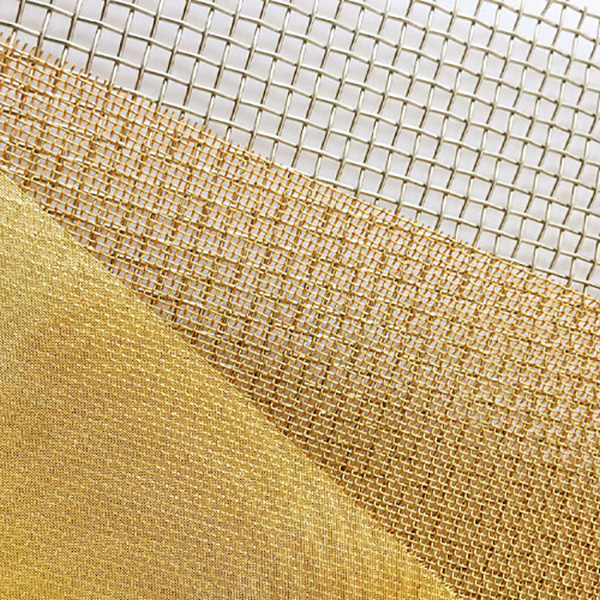

Discover the Versatility and Durability of Woven Wire Mesh

Title: Metal Woven Wire Mesh: Advancements in Quality and VersatilityIntroduction:Innovation in manufacturing and technology continues to revolutionize various industries, with metal woven wire mesh at the forefront of this transformation. With its extensive applications across sectors such as construction, filtration, food processing, and automotive, the advent of advanced metal woven wire mesh products has significantly improved overall quality and versatility. This article aims to highlight the latest advancements in metal woven wire mesh production and its growing significance in different sectors.1. Increasing Durability and Strength:The contemporary metal woven wire mesh manufacturing processes have led to the development of incredibly durable and strong products. Such advancements ensure a longer lifespan, reduced maintenance costs, and enhanced safety across multiple applications. The integration of high-quality raw materials, advanced weaving techniques, and improved quality control measures allows manufacturers to create meshes that can withstand heavy loads, extreme temperatures, corrosion, and wear and tear.2. Versatility and Customization:Metal woven wire mesh has evolved to offer an extensive range of customization options to suit specific industrial requirements. Innovations in weaving patterns, wire diameters, open area percentages, and mesh counts allow manufacturers to produce meshes that cater to diverse applications, from fine filtration to heavy-duty separation and reinforcement. This flexibility and adaptability make metal woven wire mesh an indispensable component in various industries.3. Enhanced Filtration Capabilities:One of the key areas where metal woven wire mesh has made significant strides is in filtration technology. The latest advancements in mesh design and production have greatly enhanced the filtration capabilities of these meshes. With precise and uniform openings, improved wire positioning, and increased surface area, modern metal woven wire mesh offers exceptional filtration efficiency, capturing even the finest particles and impurities. This development has considerably improved the quality and safety standards in industries such as oil and gas, pharmaceuticals, and water treatment.4. Improved Sustainability:In recent years, there has been a growing focus on sustainable manufacturing practices. Metal woven wire mesh manufacturers have responded to this demand by developing eco-friendly alternatives. By utilizing recyclable materials, reducing waste generation during production, and ensuring energy-efficient manufacturing processes, these companies contribute to a greener industry. Additionally, the longevity and durability of metal woven wire mesh enable its reuse in various applications, further enhancing its sustainability profile.5. Technological Advancements:The integration of advanced technologies in metal woven wire mesh manufacturing has further propelled its capabilities. Automation and digitization have led to improved precision in weaving, reduced production times, and minimized human errors. Furthermore, the incorporation of sensor-enabled quality control systems ensures the consistent production of high-quality meshes, meeting stringent industry standards and customer expectations.Conclusion:Metal woven wire mesh continues to be a fundamental material in numerous industries, owing to its remarkable durability, versatility, and exceptional filtration capabilities. The latest advancements in metal woven wire mesh production have significantly bolstered its performance and opened up new possibilities for its applications. As technological innovations continue to shape the manufacturing landscape, it is expected that metal woven wire mesh will continue to evolve, offering even greater benefits across various sectors.

High-Quality 316 Stainless Steel Wire Mesh Manufacturing

316 Stainless Steel Wire Mesh Manufacturer, a leading provider of high-quality wire mesh products, is proud to announce the expansion of its manufacturing facilities to meet the growing demand for stainless steel wire mesh products worldwide. The company, which has been in the industry for over two decades, has established a reputation for producing durable and reliable wire mesh solutions for various industries.The expansion of the manufacturing facilities comes in response to the increasing demand for 316 stainless steel wire mesh, which is known for its superior corrosion resistance and durability. The company has invested in state-of-the-art equipment and technology to enhance its production capabilities and meet the needs of its diverse customer base.“Our decision to expand our manufacturing facilities is driven by our commitment to providing high-quality stainless steel wire mesh products to our customers,” said a spokesperson for the company. “We have seen a steady increase in demand for our 316 stainless steel wire mesh, particularly in industries such as filtration, construction, and aerospace. By expanding our manufacturing capabilities, we aim to better serve our customers and meet their evolving needs.”316 Stainless Steel Wire Mesh Manufacturer offers a wide range of wire mesh products, including woven wire mesh, welded wire mesh, and expanded metal mesh. The company’s products are known for their exceptional strength, durability, and resistance to corrosion, making them ideal for various applications in challenging environments.In addition to its standard product offerings, the company also specializes in custom fabrication, allowing customers to obtain wire mesh products tailored to their specific requirements. The company’s team of experienced engineers and technicians works closely with customers to understand their needs and provide custom solutions that meet or exceed their expectations.The expansion of the manufacturing facilities will enable 316 Stainless Steel Wire Mesh Manufacturer to increase its production capacity and reduce lead times, ensuring that customers receive their orders in a timely manner. The company is also committed to upholding the highest standards of quality and precision in its manufacturing processes, employing rigorous quality control measures to ensure that every product meets its stringent specifications.“We take great pride in the quality of our stainless steel wire mesh products, and our expansion efforts are aimed at maintaining that standard of excellence,” the spokesperson added. “Our customers trust us to deliver reliable and durable wire mesh solutions, and we are dedicated to upholding that trust through our commitment to superior manufacturing practices.”With the expansion of its manufacturing facilities, 316 Stainless Steel Wire Mesh Manufacturer is well-positioned to meet the growing demand for stainless steel wire mesh products in the global market. The company’s investment in advanced technology and equipment reflects its dedication to innovation and continuous improvement, ensuring that it remains a leader in the wire mesh industry.As the company continues to expand its presence in the international market, it remains focused on providing exceptional customer service and support, building long-term relationships with its clients, and delivering solutions that exceed expectations. With its extensive product range, custom fabrication capabilities, and unwavering commitment to quality, 316 Stainless Steel Wire Mesh Manufacturer is poised for continued success in the industry.In conclusion, the expansion of the manufacturing facilities is a significant milestone for 316 Stainless Steel Wire Mesh Manufacturer, marking the company’s continued growth and commitment to meeting the evolving needs of its customers. With its dedication to quality, innovation, and customer satisfaction, the company is well-positioned to maintain its position as a leading provider of stainless steel wire mesh products in the global market.

Discover a Wide Range of Fabric Woven Taffeta and Other Woven & Knit Fabrics in our Textile Industry Fabric Directory

Title: Exploring the Vast Potential of the Fabric Woven Taffeta Textile IndustryIntroduction:The fabric woven taffeta textile industry is a flourishing market that encompasses a wide range of woven and knit fabrics. With a myriad of applications and versatile characteristics, taffeta, alongside other fabrics, has established itself as a fabric of choice for various industries. This article delves into the diversity and potential of the fabric woven taffeta textile industry, shedding light on its uses, market trends, and innovation.Market Overview:The fabric woven taffeta textile industry has witnessed steady growth in recent years, driven by its utilization across various sectors. Taffeta, a smooth and lightweight fabric woven with a tight weave, is highly sought after for its lustrous appearance and durability. It finds applications in the fashion and apparel industry, home furnishings, automotive textiles, and more.Fashion and Apparel:Taffeta fabric is widely used in the fashion and apparel industry due to its versatility. It is frequently employed in the creation of elegant evening gowns, bridal wear, and formal dresses, as it possesses a luxurious sheen that adds a touch of sophistication to any garment. Designers also utilize taffeta for skirts, blouses, and lingerie, owing to its crisp and structured nature.Home Furnishings:The fabric woven taffeta textile industry extends its influence to the realm of home furnishings. Taffeta fabric is used for curtains, draperies, and upholstery, where its shimmering texture can enhance the overall aesthetic of a room. The versatility of taffeta allows it to be seamlessly incorporated into both modern and traditional home décor, ensuring its continued popularity in the market.Automotive Textiles:The qualities of taffeta make it ideal for automotive applications as well. The fabric is utilized in the production of car seat covers, door panels, and headliners, thanks to its wrinkle-resistant nature and ability to withstand frequent use and cleaning. Taffeta's durability and lightweight properties contribute to its usage in the automotive industry, maintaining its position as a preferred choice for interior textiles.Emerging Trends and Innovations:The fabric woven taffeta textile industry is not stagnant; it constantly evolves to meet the needs of various industries. As sustainability continues to gain importance, manufacturers are exploring eco-friendly options in fabric production. Introducing recycled polyester taffeta, made from post-consumer plastic bottles, is a notable step in this direction.Additionally, advancements in technology have paved the way for innovative developments in the textile industry. One such example is the emergence of "smart textiles," integrating electronics into fabrics to create interactive and functional textiles. These fabrics have the potential to revolutionize several sectors, including healthcare, sports, and entertainment.Company Profile: Woven Metal FabricAmong the companies operating in the fabric woven taffeta textile industry, Woven Metal Fabric stands out for its unique product offerings. Known for their remarkable innovation, the company specializes in weaving metal fibers into fabric constructions, resulting in an extraordinary blend of strength and style.Woven Metal Fabric's creations find applications in various industries, including architecture, interior design, and apparel. Their metal-woven taffeta textiles have been utilized to create dramatic and eye-catching installations, from decorative mesh curtains to shimmering wall coverings. The fusion of metal fibers with taffeta fabric introduces an exceptional aesthetic, transforming everyday materials into works of art.Conclusion:The fabric woven taffeta textile industry is a dynamic and rapidly evolving market. Taffeta, alongside other woven and knit fabrics, caters to a wide range of industries, including fashion and apparel, home furnishings, and automotive textiles. With emerging trends and innovations, the sector continues to push boundaries and integrate sustainability and technology, ensuring its continued growth and relevance.Companies like Woven Metal Fabric exemplify the industry's ability to innovate and create extraordinary products. As the fabric woven taffeta textile industry continues to evolve, it presents exciting opportunities for designers, manufacturers, and consumers alike, setting the stage for a vibrant and prosperous future.

Top 5 Fabric Wire Options for Your Next Project

Fabric Wire, a leading provider of industrial wiring solutions, has recently announced the launch of its latest product line aimed at revolutionizing the wire and cable industry. The company, known for its high-quality and durable products, has introduced a new range of fabric-insulated wires that are designed to meet the growing demands of the industrial and commercial sectors.With over 20 years of experience in the industry, Fabric Wire has built a reputation for excellence and innovation. The company has consistently focused on research and development to create products that not only meet but exceed industry standards. This commitment to quality has made Fabric Wire a trusted partner for businesses across various sectors, including automotive, aerospace, construction, and telecommunications.The new line of fabric-insulated wires is the result of extensive research and development efforts by Fabric Wire's team of engineers and designers. The goal of the new product line is to provide customers with wiring solutions that offer superior performance, durability, and reliability. By incorporating fabric insulation, the company aims to address common issues such as abrasion resistance, flexibility, and heat resistance, which are often encountered in industrial and commercial applications.One of the key features of Fabric Wire's fabric-insulated wires is their exceptional durability. The company has utilized advanced materials and manufacturing techniques to create wires that can withstand harsh operating conditions and extreme temperatures. This makes the new product line ideal for use in challenging environments where traditional wiring solutions may fall short.In addition to durability, Fabric Wire's fabric-insulated wires also offer enhanced flexibility. The use of fabric insulation allows the wires to maintain their flexibility even in tight spaces or when subjected to constant movement. This makes them suitable for applications that require intricate wiring and where space is limited.Furthermore, the fabric insulation used in Fabric Wire's new product line provides excellent abrasion resistance. This means that the wires are less prone to damage from friction and wear, making them a reliable choice for long-term use in industrial and commercial settings.Another notable advantage of Fabric Wire's fabric-insulated wires is their superior heat resistance. The company has developed a proprietary insulation material that can withstand high temperatures without compromising performance. This makes the wires well-suited for use in applications where heat is a significant factor, such as in industrial machinery and equipment.Fabric Wire is confident that its new product line will set a new standard for wiring solutions in the industry. The company's commitment to quality and innovation, combined with its extensive expertise, positions it as a leader in providing advanced wiring solutions for businesses worldwide.The launch of the new fabric-insulated wires represents a significant milestone for Fabric Wire and underscores the company's dedication to meeting the evolving needs of its customers. With its unwavering focus on quality, reliability, and performance, Fabric Wire continues to be a trusted partner for businesses seeking top-tier wiring solutions.As Fabric Wire's latest product line gains traction in the market, the company remains committed to delivering exceptional value to its customers. Through ongoing research and development, the company aims to further expand its product offerings and reinforce its position as a leader in the wire and cable industry.Fabric Wire's new fabric-insulated wires are now available for purchase, and the company encourages businesses to explore the benefits of these innovative wiring solutions. With a proven track record of excellence and a dedication to customer satisfaction, Fabric Wire is poised to shape the future of industrial and commercial wiring solutions.

Sintered Metal Filter Elements: The Best Solution for Filtration Needs

Sintered Metal Filter Elements: The Ultimate Solution for Industrial FiltrationIn today's industrial environment, the importance of filters cannot be overstated. Filters are an essential component of any manufacturing process as they help to prevent harmful particles from entering products during the production process. One such type of filter that has gained immense popularity in recent years is sintered metal filter elements. These elements are made up of sintered metal powders and are used in a variety of applications including liquid and gas filtration. In this article, we will discuss the benefits of using sintered metal filter elements, and introduce a company that specializes in manufacturing these high-quality products.Benefits of Using Sintered Metal Filter ElementsOne of the primary benefits of using sintered metal filter elements is their ability to withstand high temperatures. They are capable of withstanding temperatures ranging from -200 to 1000°C which makes them ideal for use in high-temperature applications. Additionally, these filter elements offer excellent resistance to corrosion and erosion. They are capable of working in harsh environments and are highly resistant to chemicals, acids, and bases.Another advantage of sintered metal filter elements is their high filtration efficiency. They are designed to provide superior filtration and can capture even the smallest particles present in a liquid or gas medium. This makes them ideal for applications in the food and beverage industry where even the smallest impurities can cause contamination.Sintered metal filter elements are also highly durable and long-lasting. They are made up of high-quality metal powders that are sintered together to form a strong, robust structure. This ensures that they can withstand high pressure and mechanical stress without compromising their filtration efficiency. Additionally, sintered metal filter elements are easy to clean and maintain which makes them a cost-effective solution for industrial filtration.{} Company - A Leading Manufacturer of Sintered Metal Filter Elements{} Company is a well-known name in the field of industrial filtration. The company has been designing and manufacturing sintered metal filter elements for over 30 years and is a leading supplier of these products worldwide.{} Company's sintered metal filter elements are designed for high performance and are available in a variety of shapes, sizes, and materials to meet the specific needs of different industries. The company's product range includes sintered metal filter discs, filter cartridges, filter baskets, and filter plates.{} Company has a state-of-the-art manufacturing facility equipped with advanced production equipment and technology. Their team of skilled engineers and technicians work tirelessly to ensure that each product is of the highest quality. {} Company is committed to providing its customers with the best products and services to meet their industrial filtration needs.ConclusionSintered metal filter elements are an essential part of any industrial filtration process. Their ability to withstand high temperatures, resist corrosion and erosion, and provide high filtration efficiency makes them an ideal choice for a variety of industries. To ensure that you get the best quality sintered metal filter elements, it is essential to choose a reputable manufacturer like {} Company that has a proven track record of delivering high-quality products and exceptional service.

Copper Wire Mesh Panels: Strong and Durable Solution for Various Applications

Title: Copper Wire Mesh Panels: A Versatile Solution for Various ApplicationsIntroduction:In an era of innovation and technological advancements, companies are constantly striving to introduce products that meet the ever-growing demands of various industries. One such product is Copper Wire Mesh Panels, a versatile solution that caters to diverse applications across sectors. This news article delves into the features and applications of these panels, highlighting the significant contributions they make to modern challenges across industries.Section 1: Understanding Copper Wire Mesh PanelsCopper Wire Mesh Panels are manufactured using high-quality copper wires, woven into a durable mesh structure. This composition offers several unique properties that make these panels highly valuable for numerous applications. The robustness of the copper wire mesh ensures durability, while also allowing for flexibility and easy installation. Furthermore, the panels possess excellent thermal and electrical conductivity, making them suitable for a wide range of industrial applications.Section 2: Industrial Applications2.1 Filtration and Separation Processes:Copper Wire Mesh Panels find extensive utilization in filtration and separation processes in industries such as chemicals, pharmaceuticals, mining, and oil and gas. The mesh structure aids in the efficient separation of solid particles, while also facilitating the passage of liquids or gases. These panels are particularly beneficial for applications that involve the removal of contaminants and impurities.2.2 Architectural Applications:The aesthetic appeal of Copper Wire Mesh Panels also makes them a sought-after choice in architectural applications. These panels are commonly used in interior and exterior design elements, including facades, shading systems, stair railings, and decorative meshes. Beyond their visual appeal, these panels offer durability, weather resistance, and unobstructed airflow, enhancing the overall functionality and ambiance of architectural structures.2.3 Electrical and Electronic Applications:Copper Wire Mesh Panels are extensively utilized in electrical and electronic applications due to their superior electrical conductivity properties. They are often employed in grounding systems, electromagnetic shielding, and circuit board components. The efficient transfer of electrical signals, coupled with the panels' durability and corrosion resistance, makes them indispensable in the electronics industry.2.4 EMI/RFI Shielding:With the proliferation of electronic devices, electromagnetic interference (EMI) and radio-frequency interference (RFI) have become significant concerns. Copper Wire Mesh Panels serve as excellent shielders against EMI and RFI, effectively preventing signal interference, and enhancing overall device performance. Industries such as telecommunications, aerospace, and defense rely on these panels to ensure uninterrupted signal transmission and reception.Section 3: Benefits of Copper Wire Mesh Panels3.1 Durability and Resistance:Copper Wire Mesh Panels demonstrate exceptional durability and resistance to corrosion, oxidation, and harsh environmental conditions. These properties ensure long-lasting performance, reducing maintenance costs and increasing overall product lifespan.3.2 Versatility:The versatility of Copper Wire Mesh Panels lies in their ability to cater to a wide range of applications across diverse industries. Their adaptability enables creativity and innovation in design while maintaining functionality and performance.3.3 Sustainability:Copper itself is a highly sustainable material. By choosing Copper Wire Mesh Panels, companies contribute to sustainable practices, as copper is completely recyclable and retains its value even after multiple uses.Conclusion:Copper Wire Mesh Panels have emerged as a highly adaptable and versatile solution across various industries. Their unique properties, including durability, electrical conductivity, and aesthetic appeal, make them instrumental in meeting modern challenges. From filtration to architectural design, electrical applications, and EMI/RFI shielding, these panels continue to elevate performance standards and contribute to advancements across multiple sectors. As industries rapidly evolve, Copper Wire Mesh Panels stand as a reliable investment for present and future applications.