Discover the Latest Innovation in Filter Elements for Enhanced Efficiency

By:Admin

In today's rapidly advancing industrial world, maintaining efficient and clean filtration systems has become essential across various sectors. Epe Filter Element, a leading filtration solutions provider, has been revolutionizing the industry with their cutting-edge technology and unwavering commitment to customer satisfaction. With an extensive range of products designed for diverse applications, Epe Filter Element continues to pave the way for clean technology solutions.

Established in {insert year}, Epe Filter Element has grown to become a trusted name in the global filtration market. Their dedication to research and development, combined with a passion for innovation, has allowed them to consistently deliver state-of-the-art products to meet the evolving needs of their customers.

The core philosophy of Epe Filter Element revolves around providing efficient, reliable, and cost-effective filtration solutions. By focusing on these key principles, the company has successfully built a reputation for excellence and garnered a loyal customer base across a broad spectrum of industries.

Epe Filter Element specializes in the design and production of comprehensive filtration systems that cater to a wide range of applications, including automotive, petrochemical, pharmaceutical, electronics, food and beverage, and many more. Their product portfolio includes filter cartridges, filter bags, filter housings, filter media, and other related accessories.

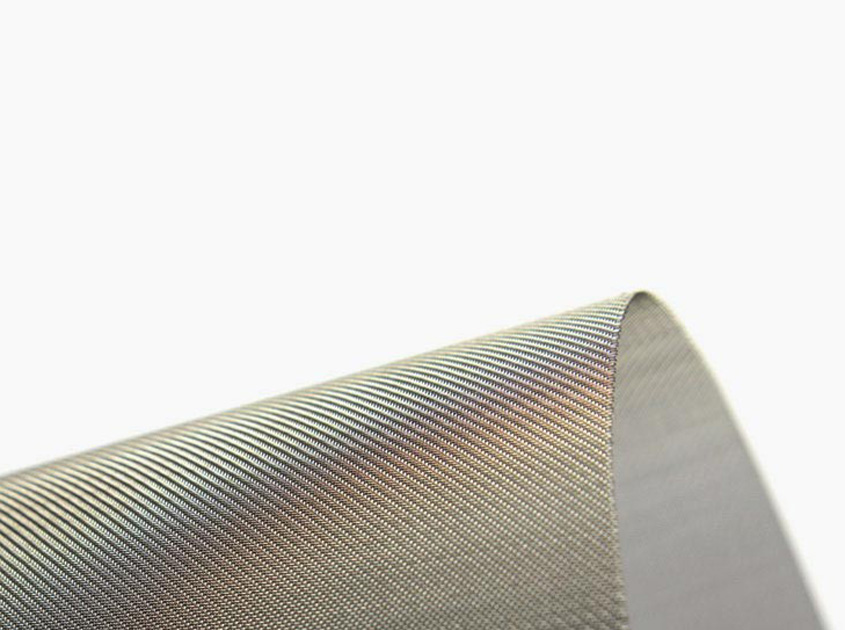

One of the company's standout offerings is their innovative filter cartridges. Engineered using advanced materials and manufacturing techniques, these cartridges offer high-performance filtration with exceptional durability. Epe Filter Element's team of experts collaborates closely with their customers to understand their specific requirements and provide customized solutions that meet their filtration needs.

Epe Filter Element's commitment to sustainability is evident in their products and processes. The company recognizes the importance of protecting the environment and reducing the carbon footprint. As a result, they continuously strive to develop eco-friendly solutions that are energy-efficient and minimize waste generation. By harnessing clean technology, Epe Filter Element ensures their products not only meet regulatory standards but also contribute to a greener future.

Furthermore, Epe Filter Element boasts a state-of-the-art manufacturing facility equipped with cutting-edge machinery and technology. Adhering to strict quality control measures, the company ensures that each product is manufactured to the highest standards of precision and reliability. Their team of highly skilled engineers and technicians continuously improve their manufacturing processes, allowing them to produce filters with consistently superior performance.

To better serve their customers, Epe Filter Element has established a robust global distribution network. With presence in numerous countries, the company provides efficient and timely delivery of products, ensuring customer satisfaction all around the world. Additionally, their dedicated sales and customer service teams are readily available to offer technical support and guidance, ensuring a seamless experience for their clients.

Epe Filter Element's commitment to excellence has garnered numerous accolades and certifications, cementing their position as a trusted filtration solutions provider. The company's ISO 9001 certification for quality management systems and ISO 14001 certification for environmental management systems further validate their dedication to delivering the best products and services.

As industries continue to evolve, there is an increasing demand for advanced filtration solutions that meet stringent requirements. Epe Filter Element, with its cutting-edge technology and unwavering commitment to customer satisfaction, emerges as a market leader in providing clean technology solutions. With their focus on innovation, sustainability, and superior manufacturing processes, Epe Filter Element is well-equipped to cater to the diverse filtration needs of industries worldwide.

In conclusion, Epe Filter Element's extensive range of filtration products, coupled with their commitment to customer satisfaction and clean technology solutions, makes them a preferred choice for companies across various industries.

Company News & Blog

Exploring the Applications and Advantages of Sintered Metal Filter Elements

Sintered Metal Filter Elements Boost Industrial PerformanceIn today's manufacturing industry, a production line's success is greatly affected by the tools it uses. One critical component of these tools is the filter element - a critical tool that maintains a production line's hydraulic systems and ensures the smooth flow of liquids and gases. As such, choosing the right filter element is vital to the process. In light of the current market demands, Sintered Metal Filter Elements are becoming increasingly popular in the industry for their efficiency and effectiveness.At the forefront of the Sintered Metal Filter Elements market is a top-tier manufacturing company. The company specializes in bringing innovative solutions to the manufacturing industry while providing exceptional customer satisfaction. The drive for excellence has seen the company invest in developing cutting-edge filter element technology that meets even the strictest industry standards.Sintered Metal FiltersThe Sintered Metal Filter Elements are built from powdered metals compressed to create a porous structure. The filter material is then sintered to a high temperature, which melts the metal particles, fusing them together to create a durable and robust structure. The manufacturing process provides the filter media with a uniform and symmetrical pore size that can efficiently remove contaminants that could have easily passed through traditional filter elements.Metal filters have several advantages over other types of filter elements. Metal filters deliver excellent performance in high-pressure or high-temperature applications, even when dealing with harsh or aggressive operating conditions, while still providing consistent filtration quality. The uniform pore size of the filter element ensures that only the targeted contaminants are removed while allowing the uncontaminated fluid or gas to pass through easily.The Sintered Metal Filter Elements are customizable with a range of materials, pore sizes, and shapes to fit the production line's specific needs. The company offers high-end filters engineered from various metal alloys such as bronze, brass, copper, stainless steel, and titanium, among others. The array of options provides a perfect filtration solution for almost every contamination scenario, including handling abrasive particles, high-temperature oils, acidic fluids, and even high-pressure hydraulic fluids.The Sintered Metal Filter Elements are designed for optimal adaptability and long service life. The unique metal structure and homogenous pore size greatly enhance the element's durability, allowing it to withstand harsh conditions or possible wear and tear. Furthermore, its enhanced structural strength provides a greater resistance to pressure, reducing the risk of filter element failure, thereby ensuring maximum service life and reducing maintenance costs.Another benefit of Sintered Metal Filter Elements is their minimal environmental impact. The design of traditional filters in the production industry often results in considerable waste, as they frequently require replacement. Sintered Metal Filter Elements, on the other hand, can be cleaned and reused, significantly reducing the need for disposal or environmental pollution. The reduced waste also helps in cost-saving, which is critical for industries looking to maximize profits and stay competitive.In conclusion, the constant drive for innovation in the industrial sector continues to lead to the development of new and improved technologies. The Sintered Metal Filter Elements is now helping industrial companies increase their productivity, reduce costs, and remain compliant while meeting stringent industry standards. The cutting-edge technology and the exceptional support offered by the leading company in this innovative industry make Sintered Metal Filter Elements the perfect solution for all industrial filter applications.

Hydraulic Oil Filter Element for Effective Filtration

Title: Langfang Weierda Filtration Equipment Co. LTD Introduces Advanced Hydraulic Oil Filter Element 8231046410Introduction:Langfang Weierda Filtration Equipment Co. LTD, a leading filtration solutions provider based in China, takes pride in announcing the launch of their advanced hydraulic oil filter element 8231046410. This cutting-edge product aims to enhance filtration efficiency and overall system performance by effectively removing impurities and maintaining oil cleanliness. With a commitment to delivering superior quality filtration systems, Weierda Filtration Equipment continues to be a trusted manufacturer and supplier in the industry.Hydraulic Oil Filter Element 8231046410: Highlighting Superior Filtration CapabilitiesThe hydraulic oil filter element 8231046410, developed by Langfang Weierda Filtration Equipment Co. LTD, is a breakthrough product that meets the evolving needs of customers in the hydraulic oil filtration industry. With its exceptional design and high-quality materials, this filtration element offers unparalleled performance and reliability.The importance of efficient oil filtration cannot be overstated. Impurities such as dirt, debris, and particulate matter can significantly impact the performance and longevity of hydraulic systems. The hydraulic oil filter element 8231046410 effectively removes these contaminants, ensuring optimal oil cleanliness within the system. This, in turn, prevents the wear and tear of expensive hydraulic components, reducing maintenance costs and enhancing the lifespan of the equipment.Advanced Features and Benefits:1. Superior Filtration Efficiency: The hydraulic oil filter element 8231046410 integrates advanced filtration technologies, enabling it to efficiently capture and remove even the smallest particles. With an impressive filtration efficiency, it delivers impeccable performance, ensuring the hydraulic system operates at its full potential.2. Enhanced Durability: Weierda Filtration Equipment Co. LTD utilizes high-quality materials in the manufacturing process of the hydraulic oil filter element, resulting in a durable product that can withstand harsh operating conditions. It ensures longevity even in demanding applications, providing customers with a cost-effective filtration solution.3. Easy Maintenance: The design of the hydraulic oil filter element 8231046410 facilitates convenient maintenance processes. With its user-friendly features, replacing the filter element is a hassle-free task, ensuring minimal downtime and uninterrupted system operation.4. Customization Options: Langfang Weierda Filtration Equipment Co. LTD understands the diverse requirements of their customers. As a result, they offer customizable options for the hydraulic oil filter element 8231046410, catering to specific filtration needs. This flexibility allows customers to tailor the product to suit various applications, ensuring optimum filtration performance.Company Introduction: Weierda Filtration Equipment Co. LTDWeierda Filtration Equipment Co. LTD is a renowned manufacturer of filtration systems, specializing in hydraulic oil filtration. With years of industry experience and a team of skilled professionals, the company has gained a reputation for delivering innovative solutions and exceptional customer service. Committed to quality, Weierda Filtration Equipment prioritizes continuous research and development to meet the evolving demands of the filtration industry.Conclusion:Langfang Weierda Filtration Equipment Co. LTD's launch of the hydraulic oil filter element 8231046410 represents a significant advancement in hydraulic oil filtration technology. With its superior filtration efficiency, durability, easy maintenance, and customization options, this product reaffirms Weierda Filtration Equipment's commitment to providing cutting-edge solutions to customers worldwide. By opting for the hydraulic oil filter element 8231046410, customers can enjoy improved system performance, extended equipment lifespan, reduced maintenance costs, and peace of mind knowing their hydraulic systems are in reliable hands.

Copper Mesh Production Ramps Up in China to Meet Growing Demand

In the world of manufacturing and industrial production, there are few things more important than the quality and reliability of materials. One such material that has proven to be indispensable is copper mesh. One company that has made significant contributions towards the production of high-quality copper mesh is China-based {Brand Name Removed}.{Brand Name Removed} has established an enviable reputation for itself in the manufacturing and production of copper mesh. The company combines innovation, quality control, and customer satisfaction to produce an exceptional product that meets the needs of its clients.The use of copper mesh finds relevance in several industries, ranging from electronics to medical equipment and filtration systems. It is a highly versatile material that is prized for its anti-corrosion properties and high thermal conductivity. Copper mesh is used in electroplating, cathodic protection, radio frequency shielding, and many other applications that require a high level of electrical conductivity.{Brand Name Removed} recognized the importance of copper mesh and has over the years invested in technology and innovation to produce high-quality copper mesh products. The company's copper mesh is produced using the latest manufacturing techniques and equipment that ensures that the final product meets the highest industry standards.One of the key advantages of using {Brand Name Removed} copper mesh is its durability. The company's copper mesh is resistant to corrosion, making it the ideal material for use in harsh environments. It is also easy to cut and shape, making it suitable for use in intricate designs.Another feature that makes {Brand Name Removed} copper mesh stand out is its efficiency in current conduction. The mesh is highly conductive, making it ideal for use in systems that require high current flow rates. The high conductivity of the mesh ensures that current flows smoothly through the system, reducing the risk of damage due to overheating.The company's commitment to quality also means that it conducts rigorous quality control checks to ensure that each batch of copper mesh produced meets the highest standards. Each batch is checked for consistency in thickness, conductivity, and other mechanical properties.{Brand Name Removed} copper mesh is available in a wide range of sizes, making it easy for clients to find the perfect copper mesh for their specific needs. The company also provides customized solutions to clients who require copper mesh products that are tailored to their unique specifications.One noteworthy application of {Brand Name Removed} copper mesh is in the medical industry. The mesh is used in wound healing and tissue engineering applications, thanks to its biocompatibility and flexibility. The copper mesh can be molded into complex shapes, making it ideal for use in reconstructive surgeries.In conclusion, {Brand Name Removed} has set the standard for high-quality copper mesh production in China and beyond. The company's commitment to innovation, quality control, and customer satisfaction have earned it a reputation as a trusted partner in the manufacturing industry. With its wide range of sizes and customized solutions, {Brand Name Removed} copper mesh is the go-to material for clients looking for high quality, dependable copper mesh products.

Unlocking the Potential of Metal Wire Cloth: A Comprehensive Guide

Metal Wire Cloth: A Company Committed to Providing High-Quality and Efficient Filtering SolutionsMetal Wire Cloth is a top-quality manufacturer of wire mesh products and solutions that has been serving various industries worldwide for over two decades. The company offers custom-made wire mesh and filtration solutions that meet a wide range of applications, from simple to complex.Headquartered in China, Metal Wire Cloth has a well-equipped manufacturing unit backed by a team of highly skilled professionals. Their production facilities are equipped with advanced machinery and operate under strict quality control standards to ensure that every product is of high quality.The company's portfolio comprises a wide range of wire mesh products, including stainless steel wire mesh, brass wire mesh, and copper wire mesh, among others. These materials are popular for their durability, corrosion resistance, and high tensile strength properties. Metal Wire Cloth's wire mesh is available in different shapes and sizes, making it easy to customize to meet specific application requirements.Their filtering solutions include filter discs, sintered filters, and filter elements for applications in the automotive, chemical, food, and beverage, and pharmaceutical industries, among others. The filter discs are made from high-quality stainless steel wire mesh and are available in various micron ratings for efficient particle filtration. The filter elements are designed to provide high filtration efficiency, low-pressure drop, and long service life. Metal Wire Cloth's filtering solutions are highly efficient and reliable, making them ideal for use in demanding filtration applications.The company's mission is to provide efficient and reliable filtration solutions that help customers meet their unique filtration needs. They achieve this goal by continuously investing in research and development to improve product quality and innovation. The company's skilled engineers and technicians work with customers to understand their specific requirements to provide customized filtering solutions that meet their unique needs.Metal Wire Cloth prides itself on its commitment to quality and customer satisfaction. They strive to ensure that every product they produce meets or exceeds customer requirements and quality standards. The company's quality control processes are designed to test products at every stage of production, from raw materials to finished products, to ensure that they meet or exceed customer specifications.In addition to their commitment to quality, Metal Wire Cloth is also dedicated to maintaining environmentally friendly manufacturing practices. The company's production facilities comply with environmental regulations and are equipped with modern technologies that reduce emissions and minimize waste.The company has established a wide distribution network that enables them to serve customers in various parts of the world. They have developed a reputation as a reliable and trustworthy supplier of high-quality wire mesh products and filtering solutions. Their customers appreciate the company's commitment to quality, innovation, and customer satisfaction.In conclusion, Metal Wire Cloth is a leading manufacturer of wire mesh products and filtration solutions that have earned a reputation for quality, efficiency, and reliability. Their commitment to providing tailored solutions to meet unique customer needs has made them an ideal partner for companies looking for reliable filtering solutions. The company's focus on quality, innovation, and customer satisfaction is evident in everything they do, making Metal Wire Cloth a brand that customers can trust.

Understanding Wire Cloth in Automotive Applications: Definition and Importance Discussed

Wire Cloth in Automotive Applications: Understanding the Role of Molybdenum (Mo) Wire ClothWire cloth is a popular material used in different industrial applications. It consists of a matrix of interlaced and interconnected wires, designed to provide strength, durability, and filtration properties. In the automotive industry, wire cloth is used in various components, such as air filters, oil filters, fuel filters, and exhaust systems.One of the key benefits of wire cloth in automotive applications is its ability to filter different types of impurities and contaminants that may negatively affect the performance and efficiency of the engine. For example, air filters made of wire cloth can prevent dust, dirt, and other airborne particles from entering the engine's combustion chamber, which can lead to reduced power, fuel economy, and increased emissions.Similarly, oil filters that incorporate wire cloth can trap metal shavings, dirt, and other impurities that may accumulate in the engine oil, ensuring optimal lubrication and preventing premature wear and tear. Fuel filters with wire cloth can also prevent dirt, rust, and other contaminants from entering the fuel system, which can cause engine stalling, decreased performance, and potential safety hazards.Another use of wire cloth in automotive applications is in the exhaust system. Wire cloth can be used as a catalytic converter substrate, providing a large surface area for the chemical reactions that convert harmful pollutants into less harmful compounds. In this case, the selection of the right type of wire cloth is critical to ensure optimal gas flow and conversion efficiency.When it comes to wire cloth for automotive applications, one of the most important factors to consider is the material composition. In particular, the inclusion of molybdenum (Mo) in the wire cloth can provide significant advantages in terms of strength, durability, and corrosion resistance.Molybdenum is a refractory metal that has excellent resistance to high temperatures, corrosion, and wear. When added to wire cloth, it enhances the material's properties, making it suitable for challenging conditions and applications. For example, molybdenum wire cloth is ideal for use in high-temperature environments, such as exhaust systems, where it can withstand the harsh conditions and maintain its structural integrity.Molybdenum wire cloth is also highly resistant to corrosion, making it suitable for use in corrosive environments, such as marine applications. Additionally, it has excellent wear resistance, which can extend the lifespan of the wire cloth and reduce maintenance costs.In conclusion, wire cloth is a versatile material that plays a crucial role in various automotive applications. Its unique properties, such as filtration, strength, and durability, make it suitable for different components, such as air filters, oil filters, fuel filters, and exhaust systems. When it comes to selecting wire cloth for automotive applications, the inclusion of molybdenum (Mo) can provide significant benefits in terms of high-temperature resistance, corrosion resistance, and wear resistance. By choosing the right wire cloth for your automotive application, you can ensure optimal performance, efficiency, and durability.

Discover the Widest Selection of Crypto Mining Accessories for Sale in South Africa

Title: A Complete Guide to Stainless Steel Hardware Cloth for Cryptocurrency MiningIntroduction:Cryptocurrency mining has gained significant popularity in recent years. As more individuals and businesses look to profit from this digital revolution, the demand for reliable and efficient mining hardware has skyrocketed. In this blog, we will explore the significance of stainless steel hardware cloth in the realm of cryptocurrency mining. Whether you're a beginner or a seasoned miner, this comprehensive guide will provide invaluable insights into the benefits and applications of this essential accessory.Understanding the Need for Cryptocurrency Mining Hardware:Cryptocurrency mining involves the process of solving complex mathematical algorithms to verify and validate transactions on a blockchain network. This process requires powerful hardware, capable of performing intensive computations. As the mining industry continues to evolve, so does the need for advanced equipment that offers enhanced durability, efficiency, and security.Introducing Stainless Steel Hardware Cloth:Stainless steel hardware cloth, also known as wire mesh or wire netting, is a versatile accessory used in various industries. Its sturdy construction and resistance to corrosion make it an ideal choice for cryptocurrency mining hardware. Stainless steel hardware cloth acts as a protective layer, preventing unwanted intrusions while allowing optimal airflow and ventilation to maintain the temperature integrity of mining rigs.Benefits of Stainless Steel Hardware Cloth for Cryptocurrency Mining:1. Enhanced Security: The durable nature of stainless steel hardware cloth ensures that your mining rigs are adequately protected from physical damage and unauthorized access. Its small, closely spaced openings effectively deter pests and prevent them from causing disruptions.2. Optimal Airflow and Ventilation: Mining rigs generate a significant amount of heat. Stainless steel hardware cloth promotes efficient airflow, reducing the risk of overheating and prolonging the lifespan of your mining equipment. The spacious design of the cloth allows proper ventilation, preventing the accumulation of dust and debris.3. Corrosion Resistance: The high-quality stainless steel used in hardware cloth offers exceptional resistance to corrosion, ensuring long-term durability even in harsh environments. This resistance is crucial for miners operating in areas with high humidity or extreme temperatures.4. Versatility: Stainless steel hardware cloth is available in various mesh sizes, wire gauges, and dimensions, making it compatible with different mining setups. It can be custom-tailored to meet specific requirements, providing miners with flexibility and ease of installation.Applications of Stainless Steel Hardware Cloth in Cryptocurrency Mining:1. Mining Enclosures: Stainless steel hardware cloth is commonly used as a protective barrier around mining rigs, ensuring adequate airflow and ventilation while offering unparalleled security.2. Rack Covers: By using stainless steel hardware cloth as a rack cover, miners can safeguard their valuable mining equipment from unwanted contact or material accumulation.3. Air Filtration Systems: Incorporating stainless steel hardware cloth into air filtration systems helps trap dust and other particles, preventing them from clogging sensitive mining components.4. Power Supply Protection: Cryptocurrency mining rigs rely heavily on power supply units. Employing stainless steel hardware cloth as a protective layer can prevent accidental contact or damage to these critical components.Conclusion:In the dynamic and competitive world of cryptocurrency mining, investing in the right hardware and accessories can significantly impact your success. Stainless steel hardware cloth offers unparalleled benefits in terms of security, airflow, ventilation, and corrosion resistance. Whether you are a mining enthusiast or a professional miner, prioritizing the protection and prolonged lifespan of your valuable mining equipment is paramount. Explore the wide range of stainless steel hardware cloth options available and secure your mining infrastructure today!Disclaimer: This blog is intended for informational purposes only and should not be considered as financial or investment advice.

Top-quality Stainless Steel Woven Wire Mesh: The Ultimate Guide

Introducing the Versatility and Durability of Stainless Woven Wire Mesh[City, Date] - In today's rapidly evolving world, industries across various sectors are constantly seeking innovative solutions to meet their specific requirements. One such solution that has gained immense popularity is stainless woven wire mesh. Renowned for its multifunctional properties, this mesh has emerged as a top choice for a wide range of applications.Stainless woven wire mesh is a versatile material composed of high-quality stainless steel wires expertly woven together to form a precise mesh pattern. This impeccable craftsmanship results in a material that possesses exceptional strength, corrosion resistance, and durability. Furthermore, it can be customized to suit the unique needs of different industries, making it a highly sought-after product in today's market.One of the key advantages of stainless woven wire mesh is its resistance to corrosion, making it suitable for use in harsh environments. The stainless steel composition ensures that the mesh remains unaffected by moisture, chemicals, or extreme temperatures, prolonging its lifespan significantly. This durability makes it an ideal choice for applications in sectors such as mining, agriculture, construction, and oil and gas, where the mesh is subjected to demanding conditions.Additionally, thanks to its woven structure, stainless woven wire mesh offers exceptional filtration capabilities. It can be tailored to achieve precise aperture sizes, allowing for the filtration of specific particle sizes. This makes it particularly useful in industries such as pharmaceuticals, food processing, and water treatment, where precise filtration is crucial.Moreover, stainless woven wire mesh also finds extensive application in the architectural and design sectors. It serves as an elegant and functional material for various applications, including interior and exterior decoration, façades, sunscreens, and balustrades. Its aesthetic appeal, combined with its durability, ensures that it not only enhances the visual appeal of spaces but also provides long-lasting functionality.One company at the forefront of manufacturing top-quality stainless woven wire mesh is [Company’s Name]. With a rich history of delivering excellence, [Company’s Name] has established itself as a leader in the industry. Their commitment to superior craftsmanship and customer satisfaction has made them a trusted partner for countless prestigious projects across the globe.[Company’s Name] offers a diverse range of stainless woven wire mesh, providing solutions to meet varying industry needs. They understand the importance of customization, allowing clients to choose the desired dimensions, patterns, and wire thicknesses to ensure a perfect fit for their specific applications. This flexibility sets [Company’s Name] apart, enabling them to cater to a wide range of sectors, including mining, agriculture, oil and gas, construction, architecture, and design.Furthermore, [Company’s Name] also operates with a strong emphasis on sustainability and eco-friendliness. Their manufacturing processes adhere to strict environmental standards, ensuring that their products have minimal impact on the planet. By continually investing in research and development, they aim to provide cutting-edge solutions that are both efficient and environmentally responsible.In conclusion, stainless woven wire mesh has emerged as a versatile and durable solution for various sectors. Its exceptional strength, corrosion resistance, and customization options make it an ideal choice for demanding applications. With a trusted industry leader like [Company’s Name] at the forefront, ensuring top-quality products and impeccable customer service, the future of stainless woven wire mesh remains bright.About [Company’s Name]:[Company’s Name] is a leading manufacturer and supplier of stainless woven wire mesh. With a commitment to superior craftsmanship, customization, and sustainability, they have become a trusted partner for industries across the globe. Their diverse product range and dedication to customer satisfaction have set them apart as a leader in the industry.Press Contact:[Company’s Name][Email][Phone Number]

Shop Online for Coarse and Match Landing Nets - Find Quality Fishing Accessories and Equipment

Title: Coarse and Match Landing Nets: The Essential Angling Accessories for Every Fishing Enthusiast Introduction:The world of angling is as diverse as the species that inhabit our waters, and having the right equipment is essential for a successful fishing experience. Among these essential tools, landing nets play a crucial role in safely capturing fish and ensuring their well-being. In this article, we will explore the significance of coarse and match landing nets and their indispensable role in the angling community.Understanding Coarse Mesh:Coarse mesh landing nets are designed to be used primarily in carp and coarse fishing. Constructed with a wider mesh pattern, these nets optimize water flow, reducing resistance while maneuvering through the water. The coarse mesh reduces the chances of damage to the fish's fins, scales, and slime, ensuring their safe release later. Coarse mesh landing nets are also favored by many anglers as they reduce drag, allowing for smooth and efficient netting.The Importance of Match Landing Nets:Match landing nets are specifically crafted for match and pleasure fishing, where delicate handling of fish is of utmost importance. They are engineered with a finer mesh, offering increased protection to the species with smaller body structures. Match nets are designed to minimize resistance when submerged, reducing the possibility of fish escaping. The use of match landing nets reflects the angling community's commitment to practicing responsible catch and release, ensuring the well-being of fish populations.The Role of Landing Nets in Sustainable Fishing Practices:In recent years, environmental consciousness and sustainable angling practices have become increasingly important. The use of the right landing nets plays a vital role in ensuring these practices are upheld. By utilizing landing nets with suitable mesh sizes, anglers minimize stress on the fish, enabling them to return to the water unharmed. Additionally, these nets allow for easy removal of hooks, further reducing the potential for injury.Modern Innovations in Landing Net Design:With advancements in technology and materials, landing net designs have evolved to maximize efficiency and performance. Contemporary landing nets often feature lightweight yet durable frames made from materials such as carbon fiber or aluminum alloys. These materials provide strength while reducing overall weight, making it easier for anglers to maneuver their nets in challenging angling situations. Furthermore, the incorporation of telescopic handles enables easier transportation without sacrificing functionality.Choosing the Right Landing Net:Selecting the ideal landing net for your angling needs relies on various factors. Consider the species you primarily target, as well as the fishing techniques employed. Coarse mesh landing nets suit larger fish, whereas match landing nets are perfect for smaller specimens. Ensure that the net's handle length is suitable for your fishing style and environment, allowing for comfortable and effective netting. Additionally, always prioritize nets that comply with local fishing regulations and ethical angling practices.In Summary:The significance of landing nets in angling cannot be overstated. Coarse mesh landing nets offer ample water flow and reduced resistance, ideal for carp and coarse fishing. Match landing nets, with their finer mesh, provide delicate handling for smaller species. Incorporating landing nets in our angling practices plays a crucial role in protecting fish populations and promoting sustainable fishing. By choosing the right landing net, we can ensure the well-being of fish and enhance our angling experience.

Complete Guide to Spring Wire Sizes for Industrial Applications

Spring Wire Size Chart: A Tool for Optimal PerformanceAs technology advances, more and more applications require springs with specific lengths and diameters. Determining the size of the spring wire to be used in the production of these springs is critical to ensuring optimal performance. Fortunately, a spring wire size chart can make the task of selecting the correct wire size easier and more efficient.A spring wire size chart is a comprehensive guide that outlines the physical attributes of wires typically used in the production of springs. It contains the necessary information that helps spring manufacturers select the appropriate wire size and specification based on the intended application of the spring.The main factors that influence the wire size selected for any spring include the load requirements, available space, and the spring's overall strength. Wire size charts typically provide essential information on a wide range of spring wire sizes, including the diameter, tensile strength, and stiffness of the wire.Manufacturers of springs use this chart as a reference guide to ensure that every spring they produce meets the required specifications. The spring wire size chart provides recommendations on the block load capacity and spring rate, which are both critical parameters of spring strength.Moreover, the spring wire size chart also helps reduce the potential of failures caused by incorrect wire selection. A spring with wires that are too thin can cause excessive stress, leading to premature failure. On the other hand, a spring with wires that are too thick can result in a stiff spring with inadequate flexibility.The use of a spring wire size chart ensures that manufacturers produce high-quality springs that meet the required specifications. Engineers and designers can also rely on the chart to provide precise measurements to guide their design choices.However, it is critical to select a reliable and reputable manufacturer that has experience in producing springs in different sizes as outlined on the wire size chart. Only a manufacturer with a broad range of experience can guarantee the production of springs that can withstand the rigors of various applications.At [Brand Name Removed], we have over [X] years of experience in producing high-quality springs. Our manufacturing process adheres to strict quality control measures that ensure all our products meet the required industry standards. We also produce springs in different wire sizes, and our experienced team can provide technical assistance to guide clients in selecting the optimal wire size for their specific application.Our spring wire size chart provides comprehensive information on wire sizes and properties as well as potential applications. We use the chart as a guide to produce springs that meet or exceed our clients' requirements while providing superior performance in various environments.In conclusion, the spring wire size chart is a valuable tool for manufacturers, engineers, and designers when designing and producing high-performance springs. It simplifies the wire selection process and ensures that the springs produced meet the required specifications. However, it is essential to select a reputable and experienced manufacturer with adequate technical expertise to ensure the production of springs that can withstand various applications' rigors.

Copper Wire Mesh Panels: Strong and Durable Solution for Various Applications

Title: Copper Wire Mesh Panels: A Versatile Solution for Various ApplicationsIntroduction:In an era of innovation and technological advancements, companies are constantly striving to introduce products that meet the ever-growing demands of various industries. One such product is Copper Wire Mesh Panels, a versatile solution that caters to diverse applications across sectors. This news article delves into the features and applications of these panels, highlighting the significant contributions they make to modern challenges across industries.Section 1: Understanding Copper Wire Mesh PanelsCopper Wire Mesh Panels are manufactured using high-quality copper wires, woven into a durable mesh structure. This composition offers several unique properties that make these panels highly valuable for numerous applications. The robustness of the copper wire mesh ensures durability, while also allowing for flexibility and easy installation. Furthermore, the panels possess excellent thermal and electrical conductivity, making them suitable for a wide range of industrial applications.Section 2: Industrial Applications2.1 Filtration and Separation Processes:Copper Wire Mesh Panels find extensive utilization in filtration and separation processes in industries such as chemicals, pharmaceuticals, mining, and oil and gas. The mesh structure aids in the efficient separation of solid particles, while also facilitating the passage of liquids or gases. These panels are particularly beneficial for applications that involve the removal of contaminants and impurities.2.2 Architectural Applications:The aesthetic appeal of Copper Wire Mesh Panels also makes them a sought-after choice in architectural applications. These panels are commonly used in interior and exterior design elements, including facades, shading systems, stair railings, and decorative meshes. Beyond their visual appeal, these panels offer durability, weather resistance, and unobstructed airflow, enhancing the overall functionality and ambiance of architectural structures.2.3 Electrical and Electronic Applications:Copper Wire Mesh Panels are extensively utilized in electrical and electronic applications due to their superior electrical conductivity properties. They are often employed in grounding systems, electromagnetic shielding, and circuit board components. The efficient transfer of electrical signals, coupled with the panels' durability and corrosion resistance, makes them indispensable in the electronics industry.2.4 EMI/RFI Shielding:With the proliferation of electronic devices, electromagnetic interference (EMI) and radio-frequency interference (RFI) have become significant concerns. Copper Wire Mesh Panels serve as excellent shielders against EMI and RFI, effectively preventing signal interference, and enhancing overall device performance. Industries such as telecommunications, aerospace, and defense rely on these panels to ensure uninterrupted signal transmission and reception.Section 3: Benefits of Copper Wire Mesh Panels3.1 Durability and Resistance:Copper Wire Mesh Panels demonstrate exceptional durability and resistance to corrosion, oxidation, and harsh environmental conditions. These properties ensure long-lasting performance, reducing maintenance costs and increasing overall product lifespan.3.2 Versatility:The versatility of Copper Wire Mesh Panels lies in their ability to cater to a wide range of applications across diverse industries. Their adaptability enables creativity and innovation in design while maintaining functionality and performance.3.3 Sustainability:Copper itself is a highly sustainable material. By choosing Copper Wire Mesh Panels, companies contribute to sustainable practices, as copper is completely recyclable and retains its value even after multiple uses.Conclusion:Copper Wire Mesh Panels have emerged as a highly adaptable and versatile solution across various industries. Their unique properties, including durability, electrical conductivity, and aesthetic appeal, make them instrumental in meeting modern challenges. From filtration to architectural design, electrical applications, and EMI/RFI shielding, these panels continue to elevate performance standards and contribute to advancements across multiple sectors. As industries rapidly evolve, Copper Wire Mesh Panels stand as a reliable investment for present and future applications.