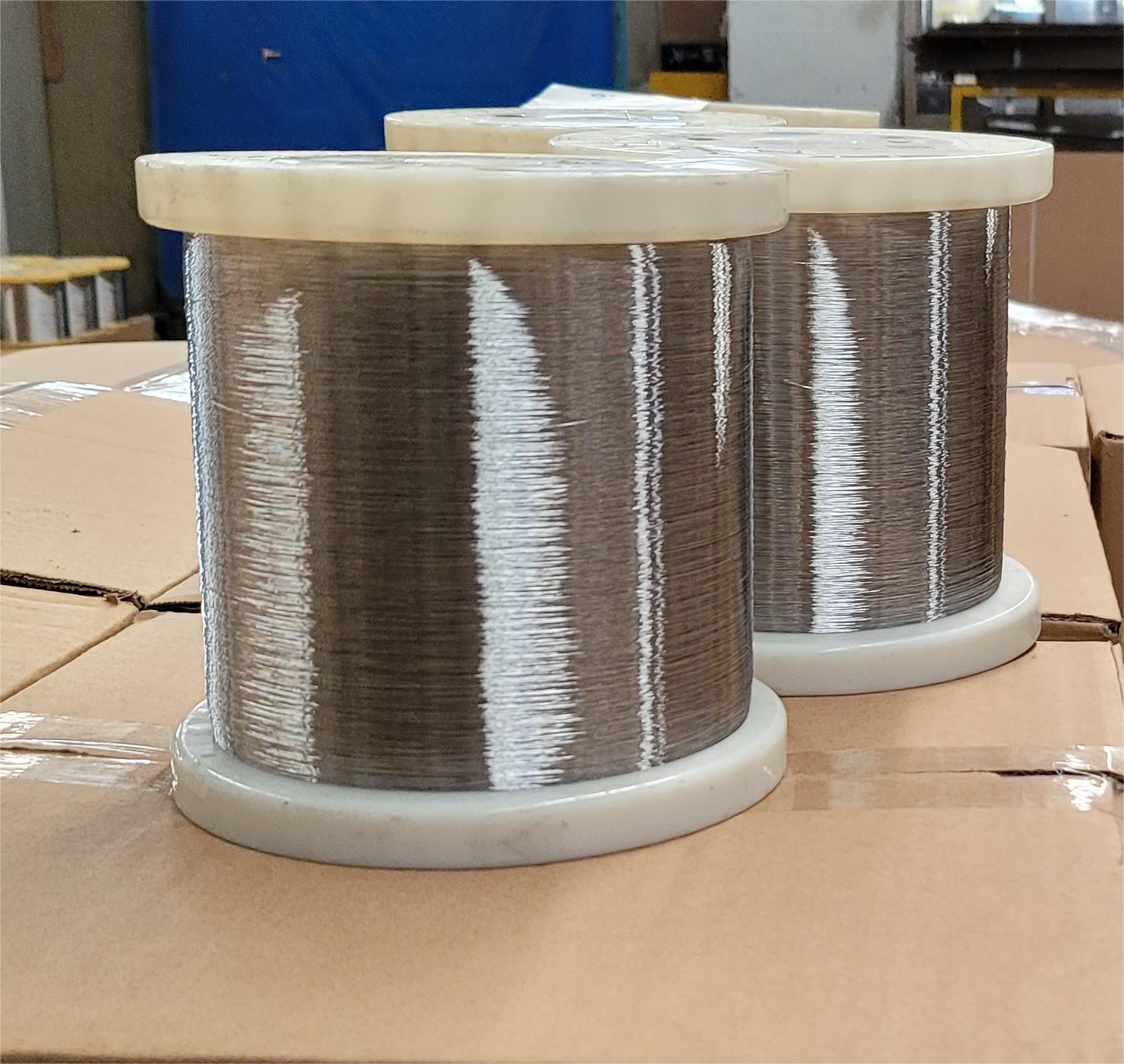

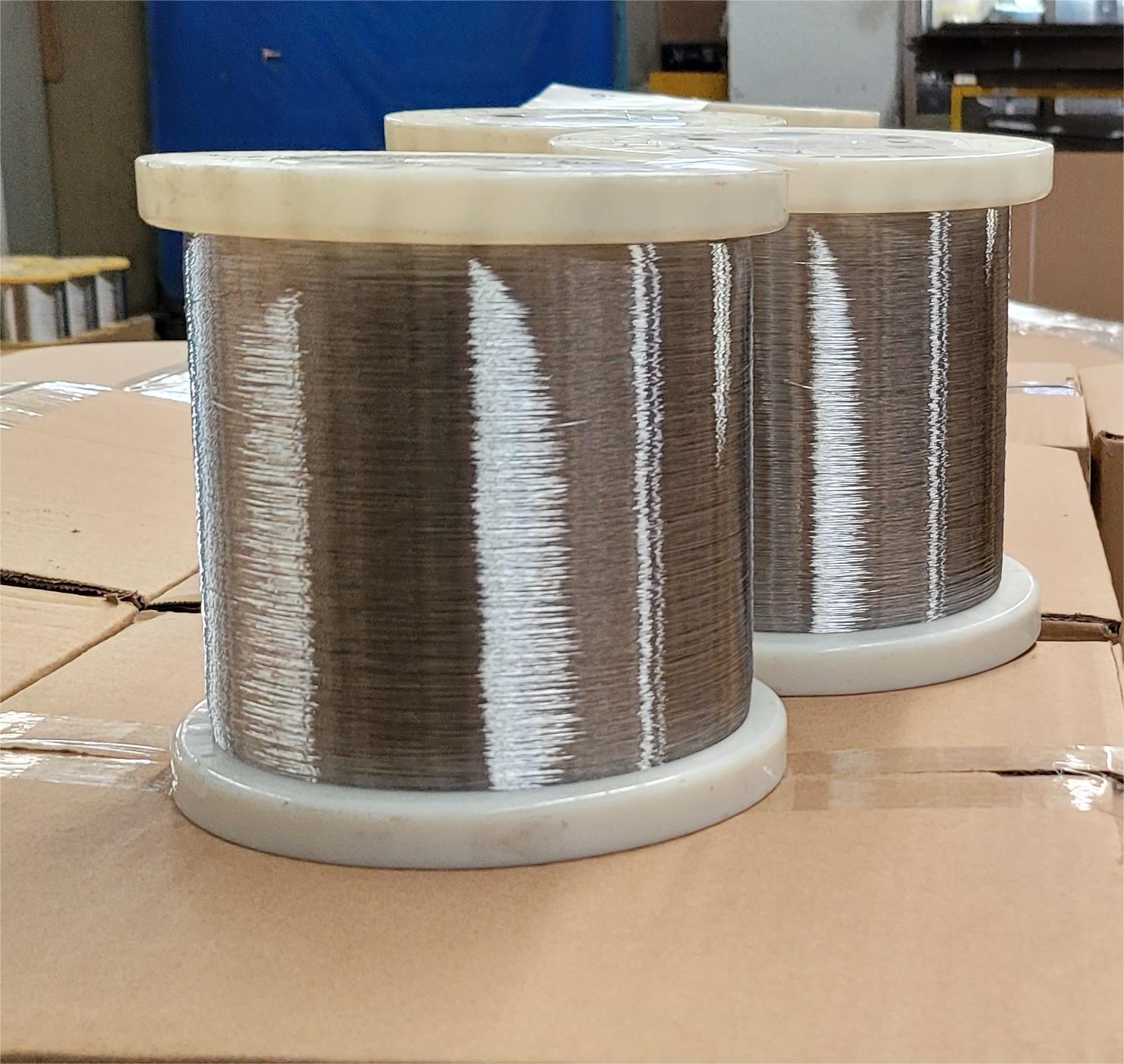

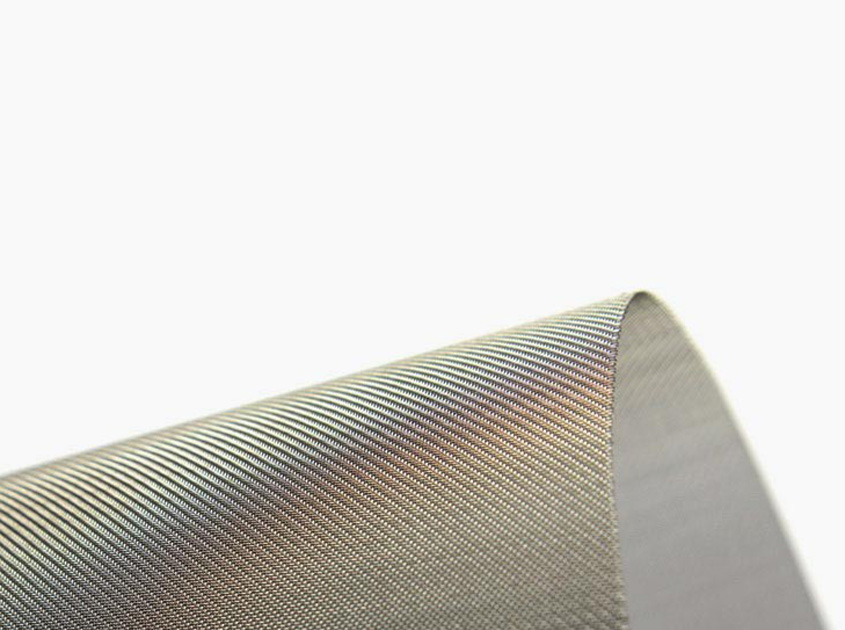

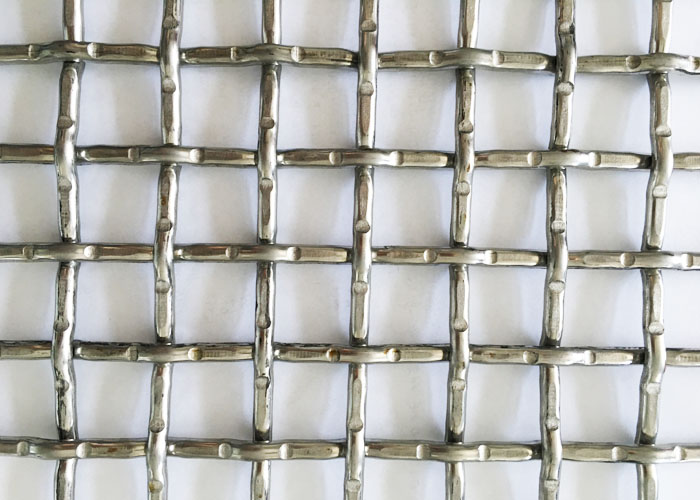

Specifications • Material: stainless steel. • Wire diameter: 0.30–6.00 mm • Surface: bright finish, dull finish

Specifications • Material: stainless steel. • Wire diameter: 0.30–6.00 mm • Surface: bright finish, dull finish | Table 1: Raw Materials & Chemical Components | |||||||||||

| Grade | Chemical Components (%)

| Tensile Strength N/mm2 (MPa) | |||||||||

| Type | C | Si | Mn | P | S | Ni | Cr | Mo | Cu | Other | |

| SUS302 | 0.15 | 1.00 | 2.00 | 0.045 | 0.030 | 8.0–10.0 | 17.0–19.0 | – | – | – | JIS standard |

| SUS304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 8.0–10.0 | 18.0–20.0 | – | – | – | JIS standard |

| SUS316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 10.0–14.0 | 16.0–18.0 | 2.0–3.0 | – | – | JIS standard |

| 321 | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 9.0–13.0 | 17.0–19.0 | – | – | Ti≥5×C% | ASTM standard |

| 347 | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 9.0–13.0 | 17.0–19.0 | – | – | Nb≥10×C% | ASTM standard |

| SUS631(J1) | 0.09 | 1.00 | 1.00 | 0.040 | 0.030 | 6.50–8.50 | 16.0–18.0 | – | – | Al: 0.75–1.5 | JIS standard |

| Note: The single value represents the maximum value in the table above. | |||||||||||

| Table 2: SUS302, SUS304, SUS316 & SUS631(J1) Stainless Steel Spring Wires –JIS Standard | ||||

| Wire Diameter D (mm) | Tensile Strength N/mm2 (MPa) | |||

| Class A | Class B | Class C | Class D | |

| SUS302-WPA SUS304-WPA SUS316-WPA | SUS302-WPB SUS304-WPB SUS304-WPBSa) | SUS631J1–WPCb) | SUS304–WPDS | |

| 0.29 ≤ D ≤ 0.40 | 1600–1850 | 2050–2300 | 1930–2180 | 1700–2000 |

| 0.40 < D ≤ 0.60 | 1950–2200 | 1850–2100 | 1650–1950 | |

| 0.60 < D ≤ 0.70 | 1530–1780 | 1850–2100 | 1800–2050 | 1550–1850 |

| 0.70 < D ≤ 0.90 | 1550–1800 | |||

| 0.90 < D ≤ 1.00 | 1500–1750 | |||

| 1.00 < D ≤ 1.20 | 1450–1700 | 1750–2000 | 1700–1950 | 1470–1720 |

| 1.20 < D ≤ 1.40 | 1420–1670 | |||

| 1.40 < D ≤ 1.60 | 1400–1650 | 1650–1900 | 1600–1850 | 1370–1620 |

| 1.60 < D ≤ 2.00 | – | |||

| 2.00 < D ≤ 2.60 | 1320–1570 | 1550–1800 | 1500–1750 | |

| 2.60 < D ≤ 4.00 | 1230–1480 | 1450–1700 | 1400–1650 | |

| 4.00 < D ≤ 6.00 | 1100–1350 | 1350–1600 | 1300–1550 | |

| Grade, Temper and Classification | |||

| Grade

| Temper

| Classification | |

| Division | Symbol | Austenitic series | |

| SUS302 | Class A Class B | WPA WPB | |

| SUS304 | Class A Class B Class D | WPA WPB, WPBSc) WPDSc) | |

| SUS316 | Class A | WPA | |

| SUS631J1 | Class C | WPC | Precipitations hardening series |

| Notec) The letter “S” at the tail of the symbols indicates wires requiring straightness. | |||

| Applicable Wire Diameter

| |

| Temper symbol | Wire Diameter D (mm) |

| WPA | 0.080 ≤ D ≤ 8.00 |

| WPB | 0.080 ≤ D ≤ 12.00 |

| WPC | 0.10 ≤ D ≤ 6.00 |

| WPBS, WPDS | 0.29 ≤ D ≤ 1.60 |

| Table 3: 321 & 347d) Stainless Steel Spring Wires – ASTM Standard | |

| Wire Diameter D (mm) | Tensile Strength N/mm2 (MPa) |

| 0.25 < D ≤ 0.38 | 1655–1860 |

| 0.38 < D ≤ 0.61 | 1620–1825 |

| 0.61 < D ≤ 1.04 | 1620–1825 |

| 1.04 < D ≤ 1.19 | 1585–1790 |

| 1.19 < D ≤ 1.37 | 1550–1760 |

| 1.37 < D ≤ 1.57 | 1515–1725 |

| 1.57 < D ≤ 1.83 | 1480–1690 |

| 1.82 < D ≤ 2.03 | 1450–1655 |

| 2.03 < D ≤ 2.34 | 1415–1620 |

| 2.34 < D ≤ 2.67 | 1380–1585 |

| 2.67 < D ≤ 3.05 | 1345–1550 |

| 3.05 < D ≤ 3.76 | 1275–1480 |

| 3.76 < D ≤ 4.22 | 1240–1450 |

| 4.22 < D ≤ 4.50 | 1170–1380 |

| 4.50 < D ≤ 5.26 | 1105–1310 |

| 5.26 < D ≤ 5.72 | 1070–1275 |

| 5.72 < D ≤ 6.35 | 1035–1240 |

| Note:d) When wire is specified in straightened and cut lengths, the minimum tensile strength shall be 90 % of the values listed in the table. | |