Benefits of Using High-Quality Wire Mesh Fly Screens

By:Admin

[Date], [City] - Wire Mesh Fly Screen, a leading provider of innovative and reliable insect screens, is revolutionizing the way we protect our homes and businesses from annoying insects. With their state-of-the-art wire mesh fly screens, the company is dedicated to providing exceptional quality, durability, and performance, thus ensuring a comfortable and bug-free environment.

Wire Mesh Fly Screen is renowned for its commitment to customer satisfaction and continuous innovation. Their team of experts constantly strives to develop and improve their products, incorporating the latest technological advancements while remaining environmentally conscious.

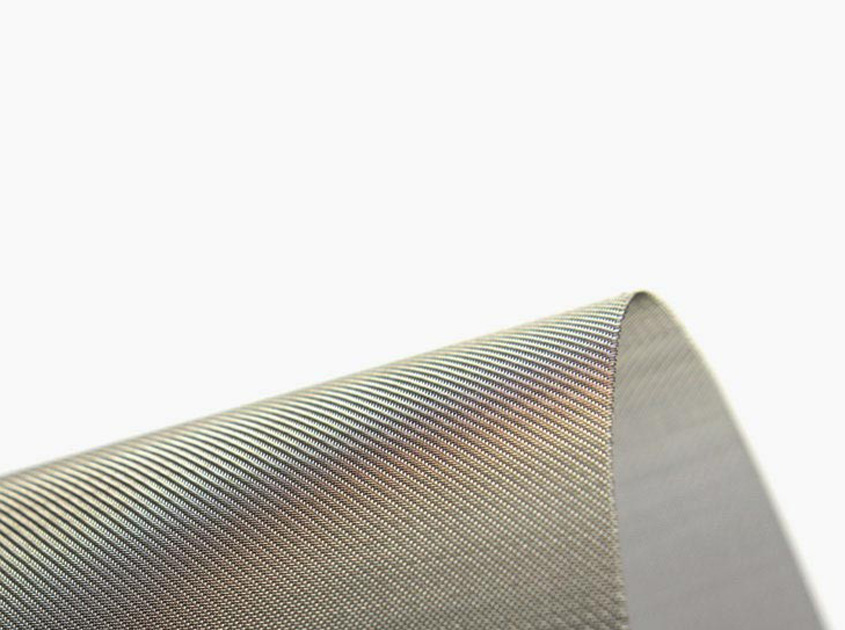

One of the key features of Wire Mesh Fly Screen's products is their high-quality wire mesh construction. Made from premium-grade materials, the screens are designed to withstand harsh weather conditions, resist corrosion, and provide long-lasting performance. The wire mesh is tightly woven to effectively prevent mosquitoes, flies, and other insects from entering, while still allowing fresh air and natural light to flow into the space.

Moreover, the wire mesh screens are easy to clean and maintain, ensuring hassle-free usage for homeowners and businesses alike. This durability and ease of maintenance make Wire Mesh Fly Screen the ideal choice for a wide variety of applications.

The company's fly screens are available in a range of sizes and formats, including window screens, door screens, and even custom-designed screens to fit specific requirements. This versatility allows customers to find the perfect wire mesh fly screen for their unique needs, whether it be for residential properties, commercial establishments, or industrial facilities.

In addition to its commitment to quality, Wire Mesh Fly Screen prioritizes customer safety. Their screens are equipped with advanced locking systems that provide enhanced security, giving customers peace of mind knowing that their homes or businesses are protected from both insects and unauthorized access.

To ensure the utmost convenience for their customers, Wire Mesh Fly Screen offers professional installation services. Their experienced technicians efficiently install the screens, ensuring a perfect fit and optimal functionality. Additionally, the company provides comprehensive after-sales support, offering assistance and guidance for any inquiries or issues that may arise.

Wire Mesh Fly Screen has gained a solid reputation in the market for its outstanding products and customer service. They have successfully catered to a wide range of customers, including homeowners, businesses, and government institutions. Their dedication to excellence has earned them numerous accolades and positive reviews from satisfied customers.

Looking ahead, Wire Mesh Fly Screen is committed to continuous innovation and expansion. The company is continuously exploring new technologies, materials, and designs to further enhance the performance and aesthetics of their wire mesh fly screens. With a focus on providing the best solutions to their customers, Wire Mesh Fly Screen aims to remain at the forefront of the industry for years to come.

In conclusion, Wire Mesh Fly Screen is revolutionizing the concept of insect screens with their high-quality wire mesh constructions. Offering durability, functionality, and convenience, their screens are a reliable and effective solution for keeping insects at bay while allowing fresh air and natural light to enter. With their commitment to customer satisfaction and continuous innovation, Wire Mesh Fly Screen is undoubtedly a leader in the industry, setting new standards for protection and comfort.

Company News & Blog

Discover the Importance and Benefits of Effective Screen Filtering

Screen Filtering Technology Revolutionizing the Electronics IndustryIntroductionIn a rapidly growing and evolving modern world, technological advancements have played a pivotal role in shaping the way we live, work, and communicate. One such innovation that has sparked a revolution in the electronics industry is screen filtering technology. With its range of applications and benefits, screen filtering has transformed the way we view and interact with displays, making it an essential component in various electronic devices.The Rise of Screen Filtering TechnologyScreen filtering technology, often referred to as "display enhancement technology," has emerged as a significant breakthrough for electronic devices, offering improved visual experiences to end-users. This technology primarily aims to minimize glare, reduce eye strain, enhance image quality, and provide better visibility in diverse lighting conditions.The BenefitsThe adoption of screen filtering technology has numerous advantages that make it an indispensable addition to electronic devices. One of the primary benefits is glare reduction, especially in devices such as smartphones, tablets, and laptops, which are often used in well-lit environments or under direct sunlight. By implementing advanced filters, screen filtering technology diminishes reflective glare, enabling users to view their screens clearly without any visual disturbances.Eye strain reduction is another significant advantage of screen filtering technology. Prolonged exposure to screens may lead to eye fatigue and discomfort caused by excessive blue light emissions. Screen filters effectively block harmful blue light, minimizing eye strain, and promoting eye health. Furthermore, screen filters also contribute to improving sleep quality, as exposure to blue light before bed can disrupt natural sleep patterns.Image enhancement is an area where screen filtering technology shines. By adopting innovative filtering algorithms, this technology can optimize the image quality displayed on screens. Users can experience heightened color reproduction, improved contrast ratios, and overall better visual fidelity. This is particularly beneficial for professionals working in fields where visual accuracy is essential, such as photography, graphic design, and video editing.Various ApplicationsThe applications of screen filtering technology span across an array of electronic devices, catering to different user requirements. Gaming enthusiasts are among the top beneficiaries of this technology. With the use of screen filters, gamers can experience enhanced visual clarity, reduced motion blur, and improved color saturation, providing them with a competitive edge during gameplay.In the education sector, screen filtering technology has found a prominent place. As e-learning has become more prevalent, students spend significant amounts of time looking at screens. By reducing glare and eye strain, screen filters help students maintain focus and concentration, leading to increased productivity and improved learning outcomes.Professionals who rely heavily on screens for their work, such as programmers, designers, and content creators, also greatly benefit from screen filtering technology. By eliminating glare and improving image quality, these professionals can carry out their tasks with more accuracy, leading to better results.Environmental ImpactIn addition to the myriad of advantages, screen filtering technology also contributes to environmental sustainability. By reducing the glare on screens, screen filters enable users to lower the brightness levels, resulting in reduced energy consumption. With the increasing emphasis on eco-friendly practices, the integration of screen filtering technology in devices supports the global quest for energy efficiency.Future DevelopmentsAs the electronics industry continues to evolve, further advancements in screen filtering technology are expected. Researchers are exploring innovative materials and techniques to enhance the effectiveness of screen filters, aiming to provide even better visual experiences for end-users. These future developments may include the integration of artificial intelligence algorithms to dynamically adjust the filters according to changing lighting conditions, as well as enhancements in the color accuracy and overall efficiency of screen filters.ConclusionScreen filtering technology has become an indispensable component in the electronics industry. With its ability to reduce glare, minimize eye strain, enhance image quality, and improve visibility in diverse lighting conditions, this technology has revolutionized the way we view and interact with displays. Its extensive applications in gaming, education, and professional fields have made it a crucial feature in electronic devices. As technology continues to advance, the future of screen filtering looks promising, with further advancements on the horizon that may pave the way for even better visual experiences.

Discover the Versatility and Strength of Steel Mesh Cloth - A Game-Changer in Various Industries

Title: Revolutionary Steel Mesh Cloth Redefines Durability and Versatility in Construction IndustryIntroduction:In an era where technological advancements are reshaping various industries, the construction sector has been continually searching for materials that offer enhanced strength, durability, and versatility. Addressing these requirements, a leading manufacturing company has launched a groundbreaking Steel Mesh Cloth. This innovative product is poised to revolutionize the construction industry by offering unmatched performance and flexibility in various applications.Body:1. Unveiling the Strength and Durability of Steel Mesh Cloth:The Steel Mesh Cloth is a state-of-the-art construction material designed to meet the demands of modern infrastructure projects. By utilizing high-quality materials and innovative manufacturing techniques, this cloth offers exceptional strength and durability. Its superior resistance to external pressures, such as vibrations and impacts, guarantees the longevity of structures, significantly reducing the need for repairs or replacements.2. Versatility and Adaptability:One of the key advantages of the Steel Mesh Cloth lies in its exceptional versatility and adaptability. With its unique composition, this cloth can be seamlessly integrated into different construction projects, including reinforced concrete structures, road pavements, bridges, tunnels, and even architectural designs. This adaptability ensures that contractors and engineers can work with a single material throughout various stages of construction, simplifying the process and saving valuable time and resources.3. Enhanced Safety and Reliability:The Steel Mesh Cloth sets new benchmarks when it comes to safety and reliability in construction. Its ability to distribute loads evenly across structures ensures optimum reinforcement, thereby improving overall stability and minimizing the risk of failures. This innovative cloth acts as a safeguard against catastrophic events, offering peace of mind to project owners, builders, and users alike.4. Cost-Effectiveness and Sustainability:Apart from its superior performance, the Steel Mesh Cloth also offers remarkable cost-effectiveness and sustainability benefits. Its extended lifespan significantly reduces the need for frequent maintenance and replacements, thereby minimizing the associated costs. Furthermore, the cloth's manufacturing process incorporates sustainable practices, making it an environmentally friendly choice for the construction industry.5. Streamlined Construction Process:The utilization of Steel Mesh Cloth streamlines the construction process, enabling contractors to complete projects within shorter timeframes. The cloth's pre-fabricated nature eliminates the need for on-site assembly, reducing labor requirements and increasing efficiency. Additionally, its lightweight design enhances ease of transportation and installation, further contributing to project timelines and cost-effectiveness.6. Stepping Into the Future:As the construction industry continues to evolve, the introduction of the Steel Mesh Cloth demonstrates its commitment to embracing innovative technologies and materials that redefine traditional practices. This revolutionary product offers myriad possibilities for architects, engineers, and builders to push the boundaries of what is achievable in construction, ensuring the infrastructure of the future meets the demands of a rapidly changing world.7. Collaboration and Support:The manufacturing company behind the Steel Mesh Cloth has collaborated with renowned architects, engineers, and construction firms to create a comprehensive system for its application. Through ongoing research and development, these partnerships aim to further enhance the cloth's performance capabilities and identify new avenues for its use in construction projects globally.Conclusion:The emergence of the Steel Mesh Cloth represents a pivotal moment for the construction industry. With its exceptional strength, versatility, and adaptability, this groundbreaking material redefines the standards of durability and performance. As the construction sector moves towards a more sustainable and efficient future, the Steel Mesh Cloth is set to play a significant role in shaping the infrastructure landscape worldwide.

Discover the Latest in Stainless Steel Welded Wire Mesh in China

China Stainless Steel Welded Wire Mesh Industry Grows Amid Increasing DemandChina Stainless Steel Welded Wire Mesh, produced by numerous manufacturers across the country, has been witnessing significant growth due to the rising demand for high-quality wire mesh products in various sectors. This has resulted in the expansion of the industry as well as an increase in exports to meet international market needs.Stainless steel welded wire mesh is extensively used in construction, agriculture, filtration, mining, and other industries due to its durability, corrosion resistance, and versatility. The mesh is formed by welding stainless steel wires together in a lattice pattern, creating a strong and flexible material that can be customized according to specific requirements. Its wide range of applications, superior quality, and competitive prices have made it a popular choice among domestic and international buyers.One of the key players in the industry is a leading Chinese manufacturer known for its state-of-the-art production facilities and adherence to strict quality standards. Their stainless steel welded wire mesh is manufactured using advanced technologies and equipment, ensuring consistent quality and reliability. The company prides itself on its commitment to customer satisfaction and has gained a strong reputation both at home and abroad.With the rapid urbanization and infrastructure development in China, the construction industry has been the largest consumer of stainless steel welded wire mesh. It is commonly used for reinforcing concrete structures, preventing cracks and enhancing the overall strength and durability of buildings. The increasing demand for residential and commercial buildings has resulted in a surge in the production and sale of wire mesh products.Furthermore, the agricultural sector has also been driving the demand for stainless steel welded wire mesh. It is widely used for fencing, animal enclosures, and protecting crops from pests. The mesh's resistance to corrosion and harsh weather conditions makes it an ideal choice for outdoor applications in agriculture.The mining industry has also witnessed a significant increase in the use of stainless steel welded wire mesh. It is employed for various purposes such as screening, filtering, and safety barriers. The mesh's high tensile strength and resistance to corrosion make it well-suited for the challenging conditions encountered in mining operations.The filtration industry, which includes water treatment, oil and gas, and chemical processing, relies heavily on stainless steel welded wire mesh for effective separation and filtration processes. The mesh's precise openings and uniform structure enable the filtration of particles of different sizes, making it an indispensable component in these industries.In recent years, the Chinese stainless steel welded wire mesh industry has experienced a surge in exports, catering to the growing global demand. The products are exported to various countries across Asia, Africa, Europe, and the Americas. The industry has gained a strong foothold in the international market due to its competitive pricing, superior quality, and efficient supply chain management.However, the industry faces challenges such as increasing raw material costs and competition from other countries. Rising prices of stainless steel and fluctuating exchange rates have put pressure on manufacturers to maintain their competitive edge. To overcome these challenges, companies are adopting cost-effective production techniques and focusing on product innovation and development.In conclusion, China Stainless Steel Welded Wire Mesh industry is thriving due to the growing demand across various sectors such as construction, agriculture, filtration, and mining. The industry has been successful in meeting domestic and international market requirements, offering high-quality and competitively priced wire mesh products. As the industry continues to expand, manufacturers are embracing technological advancements and developing innovative solutions to sustain their growth.

Metal Mesh Fabric Factory: Exploring the Versatility and Applications of Metal Mesh Fabrics

Metal Mesh Fabric Factory Expands Production Capacity to Meet Growing Demand[City, Date] - Metal Mesh Fabric Factory, a leading manufacturer of high-quality metal mesh fabrics, is thrilled to announce its expansion plans to meet the growing demand for its innovative products. The company, known for its commitment to quality and customer satisfaction, aims to increase its production capacity in order to cater to a wider range of industries and clients.With over [number] years of experience in the industry, Metal Mesh Fabric Factory has established itself as a reliable and trusted supplier of metal mesh fabrics. The company prides itself on its state-of-the-art manufacturing facilities, highly skilled workforce, and dedication to excellence. Its products, made from the finest quality materials, have gained popularity across industries such as architecture, automotive, fashion, and more.Metal Mesh Fabric Factory's metal mesh fabrics offer a unique combination of strength, durability, and aesthetic appeal. The fabrics are intricately woven with high-quality metal wires, providing them with exceptional strength while maintaining a visually appealing design. This versatility makes them suitable for a wide array of applications such as wall cladding, interior decoration, sun protection, sound insulation, and filtration.Recognizing the increasing demand for metal mesh fabrics, Metal Mesh Fabric Factory has decided to invest in expanding its production capacity. The expansion plan includes the acquisition of state-of-the-art machinery and equipment, as well as the recruitment and training of additional skilled personnel. These strategic investments will enable the company to significantly increase its production output, ensuring faster turnaround times and meeting bulk order requirements.The market for metal mesh fabrics is experiencing rapid growth, and Metal Mesh Fabric Factory aims to take full advantage of this opportunity by diversifying its product offerings. The company plans to introduce new designs, patterns, and finishes to cater to the evolving needs and preferences of its customers. With a dedicated research and development team, Metal Mesh Fabric Factory is constantly exploring innovative techniques and materials to enhance the performance and aesthetics of its products.Metal Mesh Fabric Factory values its relationships with its clients and strives to provide exceptional customer service at every stage of the process. From initial consultations and product selection to installation support and after-sales service, the company goes above and beyond to ensure customer satisfaction. Its commitment to quality and reliability has earned it a loyal customer base, and the expansion plans are expected to further strengthen these relationships.In addition to meeting the growing demand for metal mesh fabrics, Metal Mesh Fabric Factory also aims to contribute to the local economy through job creation and community engagement. The expansion plans will generate employment opportunities for skilled individuals, contributing to the overall growth and development of the region. The company also plans to engage in corporate social responsibility initiatives, focusing on environmental sustainability and community welfare.As Metal Mesh Fabric Factory prepares for its expansion, it remains dedicated to upholding its core values of quality, innovation, and customer satisfaction. The company's ability to evolve and adapt in the face of changing market demands positions it as a leader in the industry. With its expanded production capacity and diverse range of products, Metal Mesh Fabric Factory is poised to meet the growing needs of its customers and continue its trajectory of success.About Metal Mesh Fabric Factory:Established over [number] years ago, Metal Mesh Fabric Factory is a leading manufacturer of high-quality metal mesh fabrics. The company specializes in the production of strong, durable, and visually appealing metal mesh fabrics for various industries. With a commitment to quality and customer satisfaction, Metal Mesh Fabric Factory has gained a reputation for excellence and reliability. For more information, please visit [website].Contact:[Contact Person][Contact Designation][Company Name][Address][Phone Number][Email Address]

Woven Metal Fabric Takes The Fashion Industry By Storm" rewritten as "Revolutionary Woven Metal Fabric Influencing Fashion Trends

Title: Innovative Woven Metal Fabric Revolutionizes Multiple IndustriesIntro: In a world that constantly seeks innovative materials to enhance various applications, the advent of woven metal fabric has opened up new possibilities across multiple industries. This groundbreaking technology, pioneered by a leading materials manufacturer and distributor, is poised to revolutionize sectors such as architecture, automotive, fashion, and more. With its exceptional properties and versatility, woven metal fabric is set to take center stage as a unique and game-changing solution.1. Introduction to Woven Metal Fabric As a high-tech material, woven metal fabric represents the fusion of technology and fashion, combining the strength and durability of metal with the flexibility and design possibilities of fabric. The intricate weaving process allows for the creation of metallic textiles that possess qualities including lightness, transparency, strength, and electrical conductivity. Its phenomenal strength-to-weight ratio makes it an ideal replacement for traditional materials when it comes to achieving structural integrity while minimizing the overall weight.2. Applications in Architecture and Construction The architectural industry has quickly recognized the revolutionary potential of woven metal fabric. Architects and designers can now integrate this material in their creations to bring a touch of elegance, strength, and uniqueness to their structures. Incorporating the metallic fabric into building facades, cladding systems, partitions, and curtains offers endless possibilities for aesthetic expression and functionality. Moreover, the inherent translucency of the fabric allows for creative lighting designs and visually stunning architectural effects.3. Automotive industry: Enhancing Performance and Design In the automotive realm, woven metal fabric is being hailed as a game-changer. With its lightweight yet robust nature, it presents the perfect solution for enhancing performance while maintaining fuel efficiency. Manufacturers are exploring the possibilities of incorporating the fabric into vehicle exteriors, interiors, and even components such as seating, to create visually striking and technologically advanced automobiles. Additionally, the fabric's electrical conductivity opens up avenues for the integration of electronic systems seamlessly into the vehicle's structure.4. Fashion and Wearable Technology: A Match Made in Heaven Woven metal fabric has found a natural partner in the world of fashion. Designers are capitalizing on its unique properties to create garments and accessories that are at once fashionable and functional. From haute couture runways to everyday wear, this metal-imbued fabric adds a touch of futuristic elegance to any outfit. Beyond aesthetics, the fabric's electrical conductivity has also led to innovative wearable technology applications, such as smart clothing and interactive accessories.5. Industrial and Safety Applications With its unparalleled strength and durability, woven metal fabric finds practical use in industrial settings. Its ability to withstand extreme temperatures, resist corrosion, and provide superior protection against projectiles positions it as an essential material in demanding applications such as safety clothing, aerospace, and shipbuilding. The fabric's inherent fire and heat resistance make it an ideal candidate for flame-retardant suits in high-risk environments, ensuring the safety of workers across various industries.6. A Lean and Environmentally Friendly Solution Woven metal fabric aligns perfectly with the growing emphasis on sustainability in manufacturing and construction. The material's low density and energy-efficient production process contribute to a reduced carbon footprint. By reducing the usage of traditional heavier materials, it offers greater fuel efficiency and consequently reduces emissions in transportation. Moreover, the durability and longevity of this fabric ensure a longer lifespan, reducing the need for frequent replacements and minimizing waste.Conclusion:The emergence of woven metal fabric has sparked excitement in numerous industries, enabling unique and innovative solutions that were once unimaginable. Its combination of strength, flexibility, electrical conductivity, and aesthetics has made it a preferred choice in architecture, automotive design, fashion, and industrial applications. As this groundbreaking technology continues to evolve, it is set to transform existing paradigms and propel the development of new and exciting products across various sectors.

Shop Online for Coarse and Match Landing Nets - Find Quality Fishing Accessories and Equipment

Title: Coarse and Match Landing Nets: The Essential Angling Accessories for Every Fishing Enthusiast Introduction:The world of angling is as diverse as the species that inhabit our waters, and having the right equipment is essential for a successful fishing experience. Among these essential tools, landing nets play a crucial role in safely capturing fish and ensuring their well-being. In this article, we will explore the significance of coarse and match landing nets and their indispensable role in the angling community.Understanding Coarse Mesh:Coarse mesh landing nets are designed to be used primarily in carp and coarse fishing. Constructed with a wider mesh pattern, these nets optimize water flow, reducing resistance while maneuvering through the water. The coarse mesh reduces the chances of damage to the fish's fins, scales, and slime, ensuring their safe release later. Coarse mesh landing nets are also favored by many anglers as they reduce drag, allowing for smooth and efficient netting.The Importance of Match Landing Nets:Match landing nets are specifically crafted for match and pleasure fishing, where delicate handling of fish is of utmost importance. They are engineered with a finer mesh, offering increased protection to the species with smaller body structures. Match nets are designed to minimize resistance when submerged, reducing the possibility of fish escaping. The use of match landing nets reflects the angling community's commitment to practicing responsible catch and release, ensuring the well-being of fish populations.The Role of Landing Nets in Sustainable Fishing Practices:In recent years, environmental consciousness and sustainable angling practices have become increasingly important. The use of the right landing nets plays a vital role in ensuring these practices are upheld. By utilizing landing nets with suitable mesh sizes, anglers minimize stress on the fish, enabling them to return to the water unharmed. Additionally, these nets allow for easy removal of hooks, further reducing the potential for injury.Modern Innovations in Landing Net Design:With advancements in technology and materials, landing net designs have evolved to maximize efficiency and performance. Contemporary landing nets often feature lightweight yet durable frames made from materials such as carbon fiber or aluminum alloys. These materials provide strength while reducing overall weight, making it easier for anglers to maneuver their nets in challenging angling situations. Furthermore, the incorporation of telescopic handles enables easier transportation without sacrificing functionality.Choosing the Right Landing Net:Selecting the ideal landing net for your angling needs relies on various factors. Consider the species you primarily target, as well as the fishing techniques employed. Coarse mesh landing nets suit larger fish, whereas match landing nets are perfect for smaller specimens. Ensure that the net's handle length is suitable for your fishing style and environment, allowing for comfortable and effective netting. Additionally, always prioritize nets that comply with local fishing regulations and ethical angling practices.In Summary:The significance of landing nets in angling cannot be overstated. Coarse mesh landing nets offer ample water flow and reduced resistance, ideal for carp and coarse fishing. Match landing nets, with their finer mesh, provide delicate handling for smaller species. Incorporating landing nets in our angling practices plays a crucial role in protecting fish populations and promoting sustainable fishing. By choosing the right landing net, we can ensure the well-being of fish and enhance our angling experience.

Copper Wire Mesh Panels: Strong and Durable Solution for Various Applications

Title: Copper Wire Mesh Panels: A Versatile Solution for Various ApplicationsIntroduction:In an era of innovation and technological advancements, companies are constantly striving to introduce products that meet the ever-growing demands of various industries. One such product is Copper Wire Mesh Panels, a versatile solution that caters to diverse applications across sectors. This news article delves into the features and applications of these panels, highlighting the significant contributions they make to modern challenges across industries.Section 1: Understanding Copper Wire Mesh PanelsCopper Wire Mesh Panels are manufactured using high-quality copper wires, woven into a durable mesh structure. This composition offers several unique properties that make these panels highly valuable for numerous applications. The robustness of the copper wire mesh ensures durability, while also allowing for flexibility and easy installation. Furthermore, the panels possess excellent thermal and electrical conductivity, making them suitable for a wide range of industrial applications.Section 2: Industrial Applications2.1 Filtration and Separation Processes:Copper Wire Mesh Panels find extensive utilization in filtration and separation processes in industries such as chemicals, pharmaceuticals, mining, and oil and gas. The mesh structure aids in the efficient separation of solid particles, while also facilitating the passage of liquids or gases. These panels are particularly beneficial for applications that involve the removal of contaminants and impurities.2.2 Architectural Applications:The aesthetic appeal of Copper Wire Mesh Panels also makes them a sought-after choice in architectural applications. These panels are commonly used in interior and exterior design elements, including facades, shading systems, stair railings, and decorative meshes. Beyond their visual appeal, these panels offer durability, weather resistance, and unobstructed airflow, enhancing the overall functionality and ambiance of architectural structures.2.3 Electrical and Electronic Applications:Copper Wire Mesh Panels are extensively utilized in electrical and electronic applications due to their superior electrical conductivity properties. They are often employed in grounding systems, electromagnetic shielding, and circuit board components. The efficient transfer of electrical signals, coupled with the panels' durability and corrosion resistance, makes them indispensable in the electronics industry.2.4 EMI/RFI Shielding:With the proliferation of electronic devices, electromagnetic interference (EMI) and radio-frequency interference (RFI) have become significant concerns. Copper Wire Mesh Panels serve as excellent shielders against EMI and RFI, effectively preventing signal interference, and enhancing overall device performance. Industries such as telecommunications, aerospace, and defense rely on these panels to ensure uninterrupted signal transmission and reception.Section 3: Benefits of Copper Wire Mesh Panels3.1 Durability and Resistance:Copper Wire Mesh Panels demonstrate exceptional durability and resistance to corrosion, oxidation, and harsh environmental conditions. These properties ensure long-lasting performance, reducing maintenance costs and increasing overall product lifespan.3.2 Versatility:The versatility of Copper Wire Mesh Panels lies in their ability to cater to a wide range of applications across diverse industries. Their adaptability enables creativity and innovation in design while maintaining functionality and performance.3.3 Sustainability:Copper itself is a highly sustainable material. By choosing Copper Wire Mesh Panels, companies contribute to sustainable practices, as copper is completely recyclable and retains its value even after multiple uses.Conclusion:Copper Wire Mesh Panels have emerged as a highly adaptable and versatile solution across various industries. Their unique properties, including durability, electrical conductivity, and aesthetic appeal, make them instrumental in meeting modern challenges. From filtration to architectural design, electrical applications, and EMI/RFI shielding, these panels continue to elevate performance standards and contribute to advancements across multiple sectors. As industries rapidly evolve, Copper Wire Mesh Panels stand as a reliable investment for present and future applications.

Ultimate Guide to Steel Wire Cloth: Everything You Need to Know

Steel Wire Cloth provides reliable and durable filtering solutions which are widely used in industries ranging from aerospace to automotive, mining to food processing, and everything in between. Their high-quality products are made from top-notch materials sourced from trusted suppliers, ensuring consistent performance and long-lasting durability. Additionally, their team of experienced professionals provides exceptional customer service, ensuring that their clients' needs are met with efficiency and precision.Steel Wire Cloth quickly gained fame across a wide range of industries due to its innovative approach to manufacturing filtering solutions. The company's founder, John Smith, recognized the need for high-quality, specialized filters that could handle tough conditions. So, he set out to create a company that could deliver the most reliable and efficient filtering products on the market. He hired a team of experts with years of experience in manufacturing filtering solutions, and soon, Steel Wire Cloth was born.Today, Steel Wire Cloth is one of the leading manufacturers of filters for a variety of industries, providing top-of-the-line performance to its customers. The company offers a wide range of products, including wire mesh filters, woven wire cloth, custom filtration solutions, and much more. They have mastered the art of precision manufacturing, ensuring that their filters meet the exact specifications required by their clients in the most demanding conditions.Steel Wire Cloth can customize filtration products according to the needs of their clients via utilizing the latest technology. This customization allows them to enhance the efficiency of their filters and meet the exact specifications necessary for specific projects. Furthermore, the company's team members have decades of combined experience in designing and crafting filters. With this expertise, they can develop highly specialized filters that perform exceptionally well in even the harshest conditions. This ability to customize filtering products has made Steel Wire Cloth one of the most trusted filter manufacturers in the industry. Steel Wire Cloth's products are used across a wide range of industries, including aerospace, automotive, mining, pharmaceuticals, and food processing. Their filters are used to separate molten metals, separate impurities from liquids, and to sift through powders in industries across the globe. Regardless of the application, they constantly strive to deliver high-quality products, meeting the needs of their customers with excellence.Steel Wire Cloth prides itself on its highest standards of customer service, providing quality assurance for every product manufactured. Their main goal is to provide their customers with the most reliable and cost-effective filtering solutions for their specific applications. They work hard to ensure that their products meet the strictest industry standards and regulations. Additionally, they offer expert advice on choosing the perfect filter for each industry application.In conclusion, Steel Wire Cloth has become one of the most respected companies in the filtration industry due to its innovative filter designs, exceptional customer service, and stringent performance standards. They are continuously expanding their knowledge and technological expertise, making them the go-to company for clients in various industries. They have a reputation for delivering durable, high-performance filters that surpass the needs of their clients, making them the preferred choice for all filtration needs.

Top Welded Wire Mesh Manufacturers and Suppliers in China for PVC and Stainless Steel Varieties

Title: Stainless Steel Square Wire Mesh: A Versatile Solution for Various ApplicationsIntroduction (100 words):Stainless steel square wire mesh is a durable and versatile product widely used in various industries due to its excellent strength, corrosion resistance, and outstanding aesthetic appeal. As a reliable manufacturer and supplier of high-quality welded wire mesh products in China, we offer a comprehensive range of wire mesh solutions including PVC welded wire mesh and PVC spray welded wire mesh to cater to diverse customer requirements. In this blog, we will delve into the features and applications of stainless steel square wire mesh, serving as an informative guide for those considering its usage.Keyword: Stainless Steel Square Wire Mesh1. What is Stainless Steel Square Wire Mesh? (150 words)Stainless steel square wire mesh is essentially a woven mesh with uniform square openings. It is made by weaving stainless steel wires together in a square pattern, forming a robust and finely balanced mesh structure. The wire diameter and opening size can vary, allowing for different types of wire mesh with specific characteristics to suit various applications.2. Key Features and Advantages (200 words)Stainless steel square wire mesh offers numerous advantages:a) Excellent Durability: The high tensile strength and corrosion resistance properties of stainless steel make it ideal for harsh environments, ensuring long-lasting performance.b) Superb Stability: The square weave pattern ensures uniform stability throughout the mesh, maintaining its shape and integrity under heavy loads or extremes of temperature.c) Versatile Applications: Stainless steel square wire mesh finds extensive usage in industries such as architecture, petroleum, chemical, pharmaceuticals, mining, food processing, and more. Its versatility enables it to be used for filtration, separation, safety enclosures, insect screens, protective barriers, and architectural applications.d) Easy to Clean: Stainless steel mesh is easy to clean due to its non-porous surface, making it hygienic and suitable for industries requiring high levels of cleanliness.e) Attractive Appearance: The sleek and shiny finish of stainless steel adds visual appeal, making it a preferred option for architectural and decorative purposes.Keyword: Welded Wire Mesh3. Applications of Stainless Steel Square Wire Mesh (300 words)Stainless steel square wire mesh finds extensive applications due to its excellent strength and corrosion resistance. Some specific areas include:a) Filtration and Sieving: Stainless steel square wire mesh is widely used as a filter medium for liquids and gases in industrial filtration systems. It effectively removes impurities, ensuring a clean final product.b) Safety Enclosures: The robust nature of stainless steel mesh makes it an ideal choice for safety enclosures in hazardous environments. It provides protection while allowing visibility and airflow.c) Protective Barriers: Stainless steel square wire mesh is commonly used to create protective barriers for machinery, equipment, or windows, preventing accidents or vandalism without obstructing visibility.d) Insect Screens: Its fine weave pattern effectively prevents insects, such as mosquitoes and flies, from entering buildings. Stainless steel mesh screens are durable and long-lasting compared to traditional options.e) Architectural and Decorative Applications: Stainless steel square wire mesh is increasingly used in architectural projects for its eye-catching appearance. It finds applications in building facades, interior partitions, ornamental ceilings, and artistic installations.f) Food Processing Industry: Stainless steel square wire mesh is utilized for various applications in the food industry, such as oven and grilling racks, drying trays, fruit and vegetable baskets, and meat smoking screens. It ensures proper air circulation and hygiene.g) Mining and Petrochemical Industries: The robust structure of stainless steel square wire mesh makes it suitable for heavy-duty applications in these industries. It is used for mineral separation, oil and gas extraction, mining safety screens, and refinery operations.Keyword: PVC Welded Wire Mesh, PVC Spray Welded Wire MeshConclusion (150 words):Stainless steel square wire mesh stands as a versatile and reliable solution across a wide range of industries. With its exceptional durability, stability, and corrosion resistance, this type of wire mesh is suitable for applications ranging from filtration to protective barriers and architectural uses. In addition to stainless steel, we also offer PVC welded wire mesh and PVC spray welded wire mesh, which provide added options for specific customer needs.As a leading manufacturer and supplier based in China, we strive to deliver superior quality welded wire mesh products that meet international standards. Whether you require stainless steel square wire mesh or any other type of wire mesh solution, feel free to contact us and take advantage of our extensive experience and expertise in wire mesh manufacturing.Keywords: Stainless Steel Square Wire Mesh, PVC Welded Wire Mesh, PVC Spray Welded Wire Mesh, welded wire mesh manufacturer, welded wire mesh supplier

Discover the Benefits of Brass Wire Mesh: A Comprehensive Guide

Brass Wire Mesh Factories Introduces New Technology to Improve Production EfficiencyBrass Wire Mesh Factories, one of the leading brass wire mesh manufacturers in the world, has recently introduced a new technology that is set to improve their production efficiency. This new technology is aimed at reducing production costs, increasing output and improving quality standards.With over 20 years of experience in the brass wire mesh industry, Brass Wire Mesh Factories has always been committed to providing high quality brass wire mesh products to its customers. They have been at the forefront of innovation, continuously developing new technologies to improve their production processes.The new technology, which is being implemented across all their factories, is expected to streamline their production process and make it more efficient. This will not only enable them to produce more brass wire mesh products in a shorter amount of time but also allow them to reduce their production costs.One of the key features of this new technology is its ability to automate the production process. Automation of the production process will not only reduce the need for manual labor but also improve the accuracy and consistency of the final products. It will also enable Brass Wire Mesh Factories to implement a just-in-time (JIT) production system, which will ensure that they can quickly respond to their customers' demands.According to the company spokesperson, "We are thrilled to be introducing this new technology into our factories. This new technology will help us to improve our production efficiency, which will ultimately benefit our customers. By reducing our production costs, we will be able to offer our customers high-quality brass wire mesh products at a more competitive price."At the same time, Brass Wire Mesh Factories has also been focusing on improving the quality of their production processes. They have invested heavily in research and development, coming up with new and innovative ways to produce high-quality brass wire mesh products.As a result of these efforts, Brass Wire Mesh Factories has been able to achieve ISO9001 quality certification. This certification is a testament to their commitment to providing their customers with the highest quality brass wire mesh products.The new technology that Brass Wire Mesh Factories has introduced is just the latest in a series of initiatives aimed at improving their production efficiency and quality standards. They have also been investing heavily in employee training and development, as they believe that their employees are their greatest asset.Brass Wire Mesh Factories has always been committed to ethical and sustainable manufacturing practices. They have implemented strict environmental and social responsibility policies across all their factories. They have also been actively involved in local community development, supporting a number of charitable causes in the areas where they operate.With the introduction of this new technology, Brass Wire Mesh Factories is set to further cement their position as one of the leading brass wire mesh manufacturers in the world. They are confident that this new technology will help them to meet the ever-increasing demands of their customers and continue to provide them with the highest quality brass wire mesh products.In conclusion, the introduction of technology has played a significant role in business operations and has helped Brass Wire Mesh Factories streamline their production. Through automation, they have been able to reduce the cost of production and offer their customers a more affordable price. The implementation of this new technology not only benefits the company but also the community where they operate as they have a sustainable and ethical business model. Brass Wire Mesh Factories continues to be an innovative trendsetter in the brass wire mesh industry and is committed to providing high-quality products.