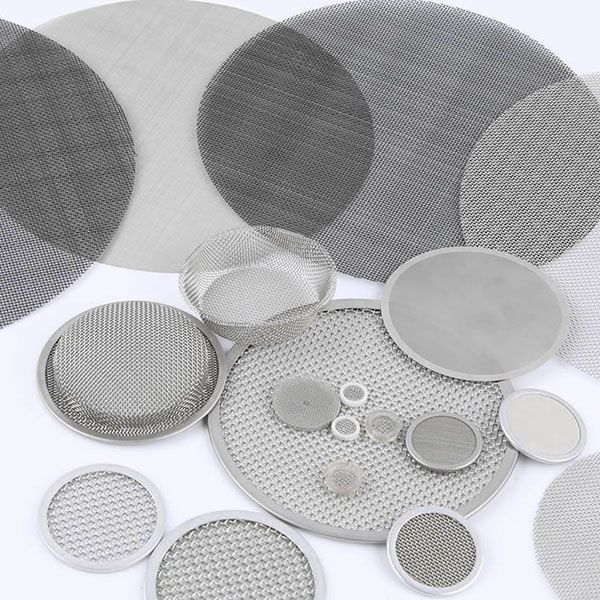

Durable and Versatile Wire Mesh for Screen Applications

By:Admin

The company's wire mesh products are known for their durability, strength, and reliability. They are designed to withstand harsh conditions and heavy use, making them ideal for demanding industrial environments. With a commitment to quality, Screen Wire Mesh ensures that its products meet the highest standards and adhere to industry regulations.

One of the key factors that set Screen Wire Mesh apart from its competitors is its dedication to continuous improvement and technological advancement. The company invests heavily in research and development to create innovative mesh solutions that offer enhanced performance and efficiency. By staying at the forefront of technological trends, Screen Wire Mesh is able to provide its customers with cutting-edge products that deliver exceptional results.

Screen Wire Mesh is also committed to sustainability and environmentally friendly practices. The company utilizes eco-friendly materials and processes in its manufacturing operations, minimizing its impact on the environment. Additionally, Screen Wire Mesh actively seeks out ways to reduce waste and optimize resource usage to create a more sustainable and responsible business model.

In addition to its high-quality products and commitment to innovation, Screen Wire Mesh places a strong emphasis on customer satisfaction. The company understands the unique needs of its clients and works closely with them to develop tailored mesh solutions that meet their specific requirements. The team at Screen Wire Mesh is dedicated to providing exceptional service and support, ensuring that customers receive the right products and assistance for their projects.

As part of its dedication to customer satisfaction, Screen Wire Mesh offers comprehensive technical support and guidance. The company's team of experienced professionals is available to provide expert advice and assistance to clients, helping them navigate the selection and installation process with confidence. This level of support sets Screen Wire Mesh apart as a trusted partner in the industry, known for its reliability and expertise.

Screen Wire Mesh also prides itself on its strong partnerships and collaborations within the industry. The company works closely with suppliers, manufacturers, and distributors to ensure a seamless supply chain and access to the best materials and resources. By leveraging these relationships, Screen Wire Mesh is able to consistently deliver top-quality products and maintain its position as a leading wire mesh provider.

Looking to the future, Screen Wire Mesh is poised for continued growth and success. The company remains committed to its core values of innovation, quality, sustainability, and customer satisfaction, driving its ongoing expansion and development. With a strong foundation and a clear vision for the future, Screen Wire Mesh is well-positioned to meet the evolving needs of the industry and continue to provide exceptional wire mesh solutions to its clients.

In conclusion, Screen Wire Mesh stands out as a premier provider of wire mesh products, known for its commitment to innovation, quality, and customer satisfaction. With its focus on continuous improvement and sustainability, the company is a trusted partner for clients across a wide range of industrial sectors. As Screen Wire Mesh continues to expand and evolve, it will undoubtedly maintain its position as a leader in the wire mesh industry.

Company News & Blog

Discover the Benefits of Shielding Mesh for Effective Protection

Title: Innovative Shielding Mesh Reinvents the Way We Protect Our EnvironmentsIntroduction:In an era of increasing technological advancements, Shielding Mesh has emerged as a groundbreaking solution to effectively shield against electromagnetic interference (EMI). Developed by a leading industry player, this product is set to revolutionize the way we protect our environments, ensuring utmost safety and uninterrupted operations. Continuously striving toward innovation in electromagnetic shielding technology, this company has set a new benchmark in EMI protection.Body:1. Understanding the Importance of Electromagnetic Shielding:Electromagnetic interference poses a significant threat to the stability and reliability of electronic devices and systems. With the proliferation of wireless communication technologies, this interference has become increasingly common. Shielding Mesh, with its advanced composition and design, offers an efficacious shield against electromagnetic radiation, preserving the integrity of sensitive components and reducing the risks associated with EMI.2. Cutting-Edge Technology Behind Shielding Mesh:Developed through rigorous research and development, Shielding Mesh embodies state-of-the-art material engineering techniques. Composed of a unique combination of conductive metals, it forms a fine mesh that effectively blocks electromagnetic radiation while allowing air and light to pass through. This mesh is adept at shielding against a wide range of frequencies, making it adaptable to various applications.3. Applications of Shielding Mesh:a) Aerospace and Defense Industry: Shielding Mesh finds extensive use in the aerospace and defense sectors, protecting sensitive electronic systems from electromagnetic interference. It ensures uninterrupted communication, enhances the security and reliability of critical onboard equipment, and contributes to mission success.b) Medical Field: In healthcare applications, Shielding Mesh plays a vital role in maintaining the reliability and safety of sensitive medical equipment, such as MRI machines, by preventing interference from external electromagnetic sources. This translates into accurate diagnoses and improved patient care.c) Telecommunications: The ever-evolving telecom industry relies heavily on effective EMI mitigation. Shielding Mesh provides an optimal solution to protect communication systems from interference, ensuring seamless connectivity and minimizing signal disruptions.d) Industrial and Residential Settings: Electromagnetic radiation can negatively impact both industrial processes and residential environments. By incorporating Shielding Mesh into infrastructural frameworks, industries can safeguard their sensitive machinery, while homeowners can create safer living spaces, immune to external EMI sources.4. Advantages and Features:a) Ease of Installation: Shielding Mesh, designed for simple and efficient installation, can be adapted to suit various requirements. Its flexible nature enables it to be seamlessly integrated into existing systems or structures.b) Cost-Effectiveness: Compared to traditional EMI protection methods, Shielding Mesh offers a cost-effective alternative while ensuring high performance and durability.c) Durability and Longevity: The high-quality materials used in Shielding Mesh prolong its service life, making it a reliable long-term investment.d) Environment-Friendly: Shielding Mesh is manufactured using environmentally-sustainable practices, reflecting the company's commitment to reducing its ecological footprint.5. Industry Recognition and Certifications:Shielding Mesh has received widespread acclaim for its superior performance and reliability. Recognized by leading industry bodies, it has obtained several certifications, including ISO 9001, ISO 14001, and RoHS compliance. These accreditations reinforce its credibility and safety standards.Conclusion:Shielding Mesh has revolutionized the field of electromagnetic shielding, providing an innovative solution to combat interference and protect sensitive electronic systems. With its cutting-edge technology, adaptability, and wide range of applications, this product has proven to be a game-changer in various sectors, including aerospace, healthcare, telecommunications, and residential settings. As the demand for EMI protection continues to rise, Shielding Mesh stands ready to safeguard our environments, ensuring uncompromised reliability and safety for the digital age.

High Quality Brass Wire Mesh for Various Applications

Brass wire mesh is a versatile and durable material that has a wide range of applications across various industries. From filtration and separation to decorative and architectural uses, brass wire mesh has proven to be an essential component in many different products and systems.One of the leading manufacturers of brass wire mesh is dedicated to providing high-quality products that meet the demands of their customers. With a focus on innovation and customer satisfaction, the company has established itself as a trusted supplier in the wire mesh industry.The company has a long history of producing high-quality brass wire mesh products, and their commitment to excellence has earned them a reputation for reliability and performance. The company's brass wire mesh is manufactured using the latest technology and equipment, ensuring that each product meets the highest standards of quality and consistency.In addition to their dedication to quality, the company also places a strong emphasis on customer service. They work closely with their clients to understand their specific needs and requirements, and they are always ready to provide expert advice and support to ensure that their customers get the best possible solution for their applications.The company's brass wire mesh is available in a wide range of specifications and configurations, making it suitable for a variety of applications. Whether it's for industrial filtration, architectural design, or decorative purposes, their brass wire mesh products can be customized to meet the unique requirements of their customers.Not only does the company offer a diverse range of brass wire mesh products, but they also provide additional services such as customization, cutting, and shaping to ensure that their customers receive the perfect solution for their needs. This level of flexibility and customization sets them apart from other suppliers in the industry and makes them a preferred choice for many businesses.With a strong focus on research and development, the company is constantly exploring new ways to improve their brass wire mesh products and expand their range of offerings. By staying at the forefront of technological advancements, they are able to deliver innovative solutions that meet the evolving needs of their customers and the industries they serve.As a reputable manufacturer with a global presence, the company is committed to sustainability and environmental responsibility. They adhere to strict standards and practices to minimize their impact on the environment, making their brass wire mesh products an eco-friendly choice for businesses seeking to reduce their carbon footprint.In conclusion, brass wire mesh is a versatile and essential material that serves a wide range of industries and applications. With a commitment to quality, innovation, and customer satisfaction, the company has established itself as a trusted supplier of brass wire mesh products. Their dedication to excellence, customer service, and sustainability makes them a top choice for businesses seeking high-quality brass wire mesh solutions.

Discover the Perfect Hydraulic Filter Element by Size for Your Needs

Hydraulic Filter Element: Finding the Perfect Fit for Your SystemIn the world of hydraulic systems, ensuring the proper filtration of hydraulic fluids is crucial for the efficient and reliable operation of machinery. One of the key components that play a significant role in this process is the hydraulic filter element. These filter elements are designed to remove contaminants and impurities from the hydraulic fluid, thus preventing damage to the system and its components.When it comes to hydraulic filter elements, one size does not fit all. Choosing the right filter element size is essential for ensuring optimal filtration performance and prolonging the life of the hydraulic system. With a wide range of hydraulic filter element sizes available in the market, it can be challenging to find the perfect fit for your specific system requirements. However, with the right knowledge and guidance, selecting the correct filter element size can be made much simpler.When it comes to selecting the right hydraulic filter element size, it is important to consider the specific requirements of the hydraulic system. Factors such as flow rate, pressure rating, and fluid viscosity play a critical role in determining the appropriate filter element size. Additionally, the type and size of contaminants that need to be removed from the hydraulic fluid also influence the selection of the filter element size.To aid in the selection process, it is essential to turn to a reputable and reliable provider of hydraulic filter elements. One such company that has established itself as a leader in the industry is {}. With a strong focus on innovation and quality, {} has been providing high-performance hydraulic filter elements to a wide range of industries for many years.{} offers a comprehensive range of hydraulic filter elements tailored to meet the diverse needs of hydraulic systems. With a keen understanding of the importance of proper filtration in hydraulic systems, {} is committed to delivering superior products that ensure the longevity and efficiency of hydraulic machinery.One of the key factors that sets {} apart from its competitors is its emphasis on customization. {} understands that every hydraulic system is unique, and as such, it offers custom sizing options for its hydraulic filter elements. This allows customers to find the perfect fit for their specific system requirements, ensuring optimal filtration performance.Another standout feature of {} is its dedication to quality and reliability. The company's hydraulic filter elements are manufactured using the highest quality materials and advanced manufacturing processes, ensuring consistent and reliable performance in the most demanding environments. With a strong emphasis on quality control, {} guarantees that its filter elements meet the highest industry standards.In addition to providing high-quality products, {} also offers expert guidance and support to help customers navigate the selection process. With a team of experienced professionals, {} is equipped to provide technical assistance and advice to ensure that customers find the ideal hydraulic filter element size for their systems.With a commitment to excellence and a customer-centric approach, {} has solidified its reputation as a trusted provider of hydraulic filter elements. Whether it's for industrial, mobile, or marine applications, {} has the expertise and resources to deliver tailored solutions to meet the unique needs of its customers.In conclusion, selecting the right hydraulic filter element size is essential for the proper functioning and longevity of hydraulic systems. With the support of a reputable company like {}, customers can benefit from high-quality, customized filter elements that are specifically designed to meet their system requirements. By choosing the right hydraulic filter element size, customers can ensure optimal filtration performance and safeguard their hydraulic systems against damage and downtime.

High-Quality Nickel Mesh for Efficient Screening of Battery Materials

Nickel Mesh for Screening of Battery MaterialsThe market for battery materials is rapidly growing, driven by the increasing demand for electric vehicles and energy storage systems. As the need for high-performance batteries continues to rise, the importance of quality screening and separation processes for battery materials becomes even more critical. One company at the forefront of advancing these processes is [Company Name], a leading manufacturer of nickel mesh for the screening of battery materials.[Company Name] has been a key player in the battery materials industry for over a decade, specializing in the production of high-quality nickel mesh that is used in various stages of battery manufacturing. The company's nickel mesh plays a crucial role in the screening and separation of battery materials, ensuring that only the finest and most uniform particles are used in the production of advanced batteries.The high-performance nickel mesh produced by [Company Name] is specially designed to meet the rigorous demands of the battery industry. It is engineered to provide excellent conductivity, corrosion resistance, and durability, making it an ideal choice for screening and separating battery materials. The company's state-of-the-art manufacturing processes and stringent quality control measures ensure that their nickel mesh consistently meets the highest standards of performance and reliability.In addition to its superior quality, [Company Name]'s nickel mesh also offers several key advantages for battery material screening. Its precise and uniform mesh structure allows for efficient and effective separation of particles, ensuring that only the desired size and shape of materials are used in battery production. This level of precision is crucial for optimizing the performance and energy density of modern batteries, ultimately leading to enhanced battery life and overall efficiency.Furthermore, the exceptional conductivity of [Company Name]'s nickel mesh contributes to the overall efficiency of battery manufacturing processes. By enabling rapid and uniform flow of materials, the nickel mesh enhances the performance and reliability of the screening and separation processes. This, in turn, results in improved consistency and quality of battery materials, ultimately leading to the production of high-performance batteries that meet the evolving industry standards.As the demand for advanced battery materials continues to surge, [Company Name] remains committed to driving innovation and excellence in the screening and separation processes. The company continuously invests in research and development to further enhance the performance and capabilities of its nickel mesh, ensuring that it remains at the forefront of battery material screening technology.With a dedicated team of experts and a state-of-the-art manufacturing facility, [Company Name] is well-positioned to meet the evolving needs of the battery industry. The company's commitment to quality, innovation, and customer satisfaction has solidified its reputation as a trusted and reliable partner for manufacturers of advanced batteries.In conclusion, [Company Name] is a leading manufacturer of high-performance nickel mesh for the screening of battery materials. With a focus on quality, precision, and innovation, the company continues to play a pivotal role in advancing the capabilities of battery material screening and separation. As the demand for high-performance batteries continues to grow, [Company Name] remains at the forefront of driving excellence and efficiency in the battery materials industry.

High-Pressure Filter Elements: Enhancing Filtering Efficiency

Title: Cutting-Edge High Pressure Filter Element Revolutionizes Filtration TechnologyIntroduction:In today's rapidly advancing industrial sector, businesses are constantly searching for innovative solutions to enhance operational efficiency, productivity, and environmental sustainability. Strengthening this quest further, an industry-leading company has recently unveiled its groundbreaking High Pressure Filter Element, poised to revolutionize the filtration technology landscape. By effectively removing contaminants from fluids under high-pressure circumstances, this cutting-edge filter element promises to deliver superior performance, exceptional quality, and unparalleled reliability across a wide range of industries.Main Body:1. The Need for Advanced Filtration Technology (100 words)In industries dealing with high-pressure fluid systems, such as oil and gas, automotive, manufacturing, and aerospace, the demand for robust and efficient filtration technology is paramount. Contaminants, such as particles, oil varnish, water, and other impurities, can greatly impact the performance and longevity of critical components. Hence, the introduction of the High Pressure Filter Element is a significant development, as it addresses these challenges with its advanced filtration capabilities.2. Unveiling the High Pressure Filter Element (150 words)Manufactured by a globally recognized company committed to technological advancements and customer satisfaction, the High Pressure Filter Element incorporates state-of-the-art design principles and cutting-edge materials. Its unique construction ensures exceptional strength, longevity, and unrivaled filtering performance, making it the ideal choice for high-pressure filtration applications. The innovative design consists of multiple layers of advanced filtration media that allow for efficient removal of contaminants without compromising fluid flow rates.3. Superior Performance and Efficiency (150 words)The High Pressure Filter Element has been extensively tested and validated to provide remarkable filtration efficiency, capable of removing particles as small as a few microns. This ensures that the filtered fluid meets or exceeds industry cleanliness specifications, safeguarding the integrity of vital equipment and reducing maintenance costs. The filter element's high dirt-holding capacity prolongs service intervals, resulting in improved operational uptime and reduced downtime. Moreover, its robust construction enables reliable operation even under extreme pressures and fluctuating conditions, ensuring consistent and high-quality filtration performance.4. Versatility and Customization Options (150 words)Recognizing the diverse needs of various industries, the High Pressure Filter Element offers a wide array of options and customization possibilities. Clients can choose from a range of filtration ratings, sizes, and configurations to match their specific requirements. With compatibility across multiple fluids, including hydraulic oils, lubricants, coolants, and process fluids, this versatile filter element caters to a broad range of applications. Additionally, advanced monitoring features such as pressure differential indicators and bypass valves can be incorporated to enhance the system's functionality and provide improved filter element change-out timelines.5. Environmental Sustainability and Cost Savings (150 words)Apart from its exceptional performance and versatility, the High Pressure Filter Element contributes significantly to environmental sustainability efforts. By effectively removing contaminants, it helps extend the service life of equipment, reducing the need for frequent component replacements, and minimizing waste generated from maintenance activities. As a result, businesses can experience substantial cost savings in terms of replacement parts, downtime, and disposal. Furthermore, the filter element's optimized design and advanced materials promote energy efficiency, ensuring that the filtration process consumes minimal power, which aligns with the company's commitment to reducing carbon footprints.Conclusion:The introduction of the High Pressure Filter Element heralds a new era in filtration technology, providing industries with a cutting-edge solution that delivers superior performance, exceptional quality, and unwavering reliability. This innovative filter element addresses the critical need for advanced filtration capabilities in high-pressure fluid systems, safeguarding equipment while reducing maintenance costs and environmental impact. With its versatility, customization options, and commitment to sustainability, this groundbreaking product promises to create a lasting impact on various industries, contributing to a more efficient, productive, and environmentally-conscious future.

Metal Mesh Fabric Factory: Exploring the Versatility and Applications of Metal Mesh Fabrics

Metal Mesh Fabric Factory Expands Production Capacity to Meet Growing Demand[City, Date] - Metal Mesh Fabric Factory, a leading manufacturer of high-quality metal mesh fabrics, is thrilled to announce its expansion plans to meet the growing demand for its innovative products. The company, known for its commitment to quality and customer satisfaction, aims to increase its production capacity in order to cater to a wider range of industries and clients.With over [number] years of experience in the industry, Metal Mesh Fabric Factory has established itself as a reliable and trusted supplier of metal mesh fabrics. The company prides itself on its state-of-the-art manufacturing facilities, highly skilled workforce, and dedication to excellence. Its products, made from the finest quality materials, have gained popularity across industries such as architecture, automotive, fashion, and more.Metal Mesh Fabric Factory's metal mesh fabrics offer a unique combination of strength, durability, and aesthetic appeal. The fabrics are intricately woven with high-quality metal wires, providing them with exceptional strength while maintaining a visually appealing design. This versatility makes them suitable for a wide array of applications such as wall cladding, interior decoration, sun protection, sound insulation, and filtration.Recognizing the increasing demand for metal mesh fabrics, Metal Mesh Fabric Factory has decided to invest in expanding its production capacity. The expansion plan includes the acquisition of state-of-the-art machinery and equipment, as well as the recruitment and training of additional skilled personnel. These strategic investments will enable the company to significantly increase its production output, ensuring faster turnaround times and meeting bulk order requirements.The market for metal mesh fabrics is experiencing rapid growth, and Metal Mesh Fabric Factory aims to take full advantage of this opportunity by diversifying its product offerings. The company plans to introduce new designs, patterns, and finishes to cater to the evolving needs and preferences of its customers. With a dedicated research and development team, Metal Mesh Fabric Factory is constantly exploring innovative techniques and materials to enhance the performance and aesthetics of its products.Metal Mesh Fabric Factory values its relationships with its clients and strives to provide exceptional customer service at every stage of the process. From initial consultations and product selection to installation support and after-sales service, the company goes above and beyond to ensure customer satisfaction. Its commitment to quality and reliability has earned it a loyal customer base, and the expansion plans are expected to further strengthen these relationships.In addition to meeting the growing demand for metal mesh fabrics, Metal Mesh Fabric Factory also aims to contribute to the local economy through job creation and community engagement. The expansion plans will generate employment opportunities for skilled individuals, contributing to the overall growth and development of the region. The company also plans to engage in corporate social responsibility initiatives, focusing on environmental sustainability and community welfare.As Metal Mesh Fabric Factory prepares for its expansion, it remains dedicated to upholding its core values of quality, innovation, and customer satisfaction. The company's ability to evolve and adapt in the face of changing market demands positions it as a leader in the industry. With its expanded production capacity and diverse range of products, Metal Mesh Fabric Factory is poised to meet the growing needs of its customers and continue its trajectory of success.About Metal Mesh Fabric Factory:Established over [number] years ago, Metal Mesh Fabric Factory is a leading manufacturer of high-quality metal mesh fabrics. The company specializes in the production of strong, durable, and visually appealing metal mesh fabrics for various industries. With a commitment to quality and customer satisfaction, Metal Mesh Fabric Factory has gained a reputation for excellence and reliability. For more information, please visit [website].Contact:[Contact Person][Contact Designation][Company Name][Address][Phone Number][Email Address]

Introduction to Plain Weave: A Versatile and Widely Used Wire Mesh

Plain weave wire mesh is a versatile and widely used material in a variety of industries. Its unique construction and properties make it an ideal option for a range of applications, making it a popular and reliable choice for many different purposes. Whether you are looking for a material that is durable, flexible, or easy to work with, plain weave wire mesh is a great option to consider.One of the main benefits of plain weave wire mesh is its simplicity. The weave is made by running wires parallel to each other in one direction, and then weaving other wires perpendicular to them. This creates a mesh pattern that is uniform and consistent, with each wire evenly distributed throughout the fabric. This simple construction makes the material easy to work with, and allows it to be used in a variety of different ways.One of the most common uses for plain weave wire mesh is in the construction of screens and filters. Its fine mesh pattern allows air and liquid to pass through, while keeping out larger particles and debris. This makes it a popular choice for applications such as window screens, dust covers, and HVAC systems.In addition to its use as a filter or screen, plain weave wire mesh is also frequently used for reinforcement and support. Its strong construction makes it ideal for use in industrial settings, where it can help to add strength and stability to machinery and other equipment. It is also commonly used in construction, where it can serve as a reinforcing material for building materials such as concrete and plaster.Plain weave wire mesh is also a popular option for decorative purposes. Its uniform, grid-like pattern can be visually appealing, and it is often used for decorative accents or to add texture to surfaces such as walls and ceilings. It can also be used in art and design, where its unique properties can be used to create interesting and dynamic pieces.Overall, plain weave wire mesh is a highly versatile and useful material that can be used in a variety of different applications. Whether you are looking for a material that is strong, flexible, or visually appealing, plain weave wire mesh is a great option to consider. So if you are in need of a reliable and high-quality material for your next project, be sure to check out plain weave wire mesh and see how it can work for you.

Discover a Wide Range of Fabric Woven Taffeta and Other Woven & Knit Fabrics in our Textile Industry Fabric Directory

Title: Exploring the Vast Potential of the Fabric Woven Taffeta Textile IndustryIntroduction:The fabric woven taffeta textile industry is a flourishing market that encompasses a wide range of woven and knit fabrics. With a myriad of applications and versatile characteristics, taffeta, alongside other fabrics, has established itself as a fabric of choice for various industries. This article delves into the diversity and potential of the fabric woven taffeta textile industry, shedding light on its uses, market trends, and innovation.Market Overview:The fabric woven taffeta textile industry has witnessed steady growth in recent years, driven by its utilization across various sectors. Taffeta, a smooth and lightweight fabric woven with a tight weave, is highly sought after for its lustrous appearance and durability. It finds applications in the fashion and apparel industry, home furnishings, automotive textiles, and more.Fashion and Apparel:Taffeta fabric is widely used in the fashion and apparel industry due to its versatility. It is frequently employed in the creation of elegant evening gowns, bridal wear, and formal dresses, as it possesses a luxurious sheen that adds a touch of sophistication to any garment. Designers also utilize taffeta for skirts, blouses, and lingerie, owing to its crisp and structured nature.Home Furnishings:The fabric woven taffeta textile industry extends its influence to the realm of home furnishings. Taffeta fabric is used for curtains, draperies, and upholstery, where its shimmering texture can enhance the overall aesthetic of a room. The versatility of taffeta allows it to be seamlessly incorporated into both modern and traditional home décor, ensuring its continued popularity in the market.Automotive Textiles:The qualities of taffeta make it ideal for automotive applications as well. The fabric is utilized in the production of car seat covers, door panels, and headliners, thanks to its wrinkle-resistant nature and ability to withstand frequent use and cleaning. Taffeta's durability and lightweight properties contribute to its usage in the automotive industry, maintaining its position as a preferred choice for interior textiles.Emerging Trends and Innovations:The fabric woven taffeta textile industry is not stagnant; it constantly evolves to meet the needs of various industries. As sustainability continues to gain importance, manufacturers are exploring eco-friendly options in fabric production. Introducing recycled polyester taffeta, made from post-consumer plastic bottles, is a notable step in this direction.Additionally, advancements in technology have paved the way for innovative developments in the textile industry. One such example is the emergence of "smart textiles," integrating electronics into fabrics to create interactive and functional textiles. These fabrics have the potential to revolutionize several sectors, including healthcare, sports, and entertainment.Company Profile: Woven Metal FabricAmong the companies operating in the fabric woven taffeta textile industry, Woven Metal Fabric stands out for its unique product offerings. Known for their remarkable innovation, the company specializes in weaving metal fibers into fabric constructions, resulting in an extraordinary blend of strength and style.Woven Metal Fabric's creations find applications in various industries, including architecture, interior design, and apparel. Their metal-woven taffeta textiles have been utilized to create dramatic and eye-catching installations, from decorative mesh curtains to shimmering wall coverings. The fusion of metal fibers with taffeta fabric introduces an exceptional aesthetic, transforming everyday materials into works of art.Conclusion:The fabric woven taffeta textile industry is a dynamic and rapidly evolving market. Taffeta, alongside other woven and knit fabrics, caters to a wide range of industries, including fashion and apparel, home furnishings, and automotive textiles. With emerging trends and innovations, the sector continues to push boundaries and integrate sustainability and technology, ensuring its continued growth and relevance.Companies like Woven Metal Fabric exemplify the industry's ability to innovate and create extraordinary products. As the fabric woven taffeta textile industry continues to evolve, it presents exciting opportunities for designers, manufacturers, and consumers alike, setting the stage for a vibrant and prosperous future.

High-Quality Insect Screens Mesh for Sale - Find the Best Deals Now

Insect Screens Mesh Factory is a renowned company that specializes in the production of high-quality insect screens for doors and windows. The company has been in the industry for over a decade and has established itself as a leader in providing insect protection solutions for residential and commercial properties.With a state-of-the-art manufacturing facility and a team of skilled professionals, Insect Screens Mesh Factory is committed to delivering superior products that offer both functionality and aesthetic appeal. The company's products are designed to effectively keep out insects while allowing for proper ventilation and natural light to enter the space.Insect Screens Mesh Factory offers a wide range of insect screen options, including retractable screens, magnetic screens, and fixed frame screens, to cater to the diverse needs of their customers. The company also provides customized solutions to meet specific requirements, ensuring that every client receives a product that perfectly fits their doors and windows.The team at Insect Screens Mesh Factory takes pride in using only the highest quality materials in their manufacturing process. The screens are constructed using durable and weather-resistant materials that are designed to withstand the elements and provide long-term protection against insects. This commitment to quality ensures that customers receive products that are built to last and perform at optimal levels.In addition to their focus on product quality, Insect Screens Mesh Factory is dedicated to providing exceptional customer service. The company's team of professionals is highly knowledgeable and experienced in the insect screen industry, allowing them to offer expert advice and guidance to customers. Whether it's selecting the right product for a specific application or providing installation assistance, the team at Insect Screens Mesh Factory is committed to ensuring a seamless and satisfying experience for every client.Furthermore, Insect Screens Mesh Factory is dedicated to staying at the forefront of innovation in the industry. The company continuously invests in research and development to improve their existing products and develop new solutions to meet evolving customer needs. This commitment to innovation has enabled Insect Screens Mesh Factory to stay ahead of the competition and maintain its position as a leading provider of insect protection solutions.With a strong focus on quality, customer service, and innovation, Insect Screens Mesh Factory has earned a stellar reputation in the industry. The company's products are trusted by homeowners, businesses, and builders alike, and are known for their reliability and effectiveness in keeping out insects.Insect Screens Mesh Factory's dedication to excellence has also earned the company recognition from industry organizations and associations. The company has received accolades for its superior products and commitment to customer satisfaction, further solidifying its position as a trusted provider of insect screens.As the demand for insect protection solutions continues to grow, Insect Screens Mesh Factory remains committed to meeting the needs of its customers and providing top-notch products and services. The company's unwavering dedication to quality, innovation, and customer satisfaction sets it apart as a leader in the industry, and positions it for continued success in the future.

High Quality Ss Woven Wire Mesh 24x110 for Various Applications

Ss Woven Wire Mesh 24x110 is a high-quality product that has gained popularity in various industrial and commercial applications. This wire mesh is known for its strength, durability, and versatility, making it an ideal choice for a wide range of uses.This Ss woven wire mesh is manufactured by {}, a leading company in the field of wire mesh and related products. With a strong focus on quality and innovation, {} has been at the forefront of developing and producing industry-leading wire mesh products for over two decades.The Ss Woven Wire Mesh 24x110 is one of the company's flagship products, known for its precise construction and superior performance. It is made from high-quality stainless steel wire, which provides excellent resistance to corrosion, heat, and chemical damage. This makes it suitable for applications in demanding environments such as filtration, separation, and protection.The 24x110 designation of the wire mesh refers to the number of wires per inch in the warp and weft directions, respectively. This configuration results in a fine mesh with a relatively high open area, making it suitable for applications that require precision filtration and excellent throughput.The Ss Woven Wire Mesh 24x110 is commonly used in industries such as pharmaceuticals, food and beverage, chemical processing, and oil and gas. It can be manufactured into various forms, including flat sheets, discs, cylinders, and custom shapes, to meet specific application requirements. This flexibility in manufacturing allows {} to cater to a wide range of customer needs, making them a preferred supplier for many businesses.In addition to its standard product offerings, the company also provides custom solutions for unique applications. Their team of experienced engineers and technicians work closely with clients to understand their specific requirements and develop tailored wire mesh products that meet their needs. This level of customization sets {} apart from other suppliers in the industry and has earned them a reputation for excellence.With a strong commitment to quality and customer satisfaction, {} ensures that all their products, including the Ss Woven Wire Mesh 24x110, undergo rigorous testing and inspection processes. This guarantees that the wire mesh meets the highest standards for performance, consistency, and reliability. Customers can have confidence in the quality of the products they receive from {} and trust that they will perform as expected in their applications.Furthermore, {} is dedicated to sustainability and environmental responsibility in their manufacturing processes. They source their raw materials from reputable suppliers and adhere to strict environmental regulations to minimize their impact on the planet. This commitment to sustainability resonates with many of their clients who value ethical and responsible business practices.In conclusion, the Ss Woven Wire Mesh 24x110 from {} is a top-quality product that offers exceptional performance and versatility for a wide range of industrial applications. With its superior construction, durability, and customization options, it has become a preferred choice for businesses across various industries. As {} continues to lead the way in wire mesh innovation, customers can expect to see even more advanced and effective products from them in the future.